Hot forging in the fashion sector

Hot forging presses are also used in the fashion industry manufacturing.

The worldwide fashion sector is characterized by extremely significant business volumes: around 3 thousand billion euros and it employs 50 million people.

Italy is one of main districts for the fashion industry with historic brands and production chains deeply rooted in the territory.

The sector is affected by global uncertainties linked to inflation, geopolitical tensions, post-Covid recovery but double-digit growth is estimated in the coming years. The increase in business volume is possible thanks to a high dynamism full of creativity and style which canalizes an important flow of news and innovations every season.

The digitalization of sales channels and operational departments and the near-shoring approach have created the need to make the manufacturing process increasingly productive and efficient.

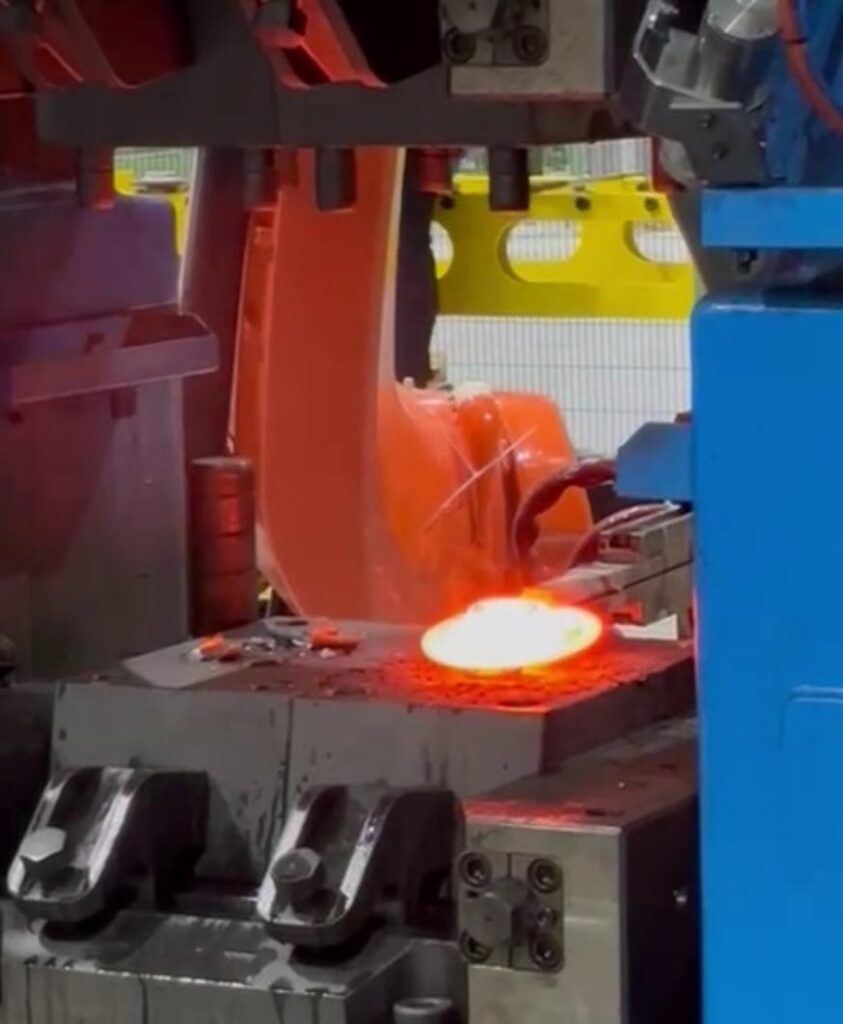

Metals hot forging is a key operation to characterize fashion products and accessories. The logos of the major brands applied on bags, shoes, clothes and belts are made through hot forging and then finished with other downstream processes.

Mecolpress has been the protagonist of this continuous growth process, offering technologically advanced forging solutions with the aim of:

- Increasing production capacity up to 1500 pieces per hour;

- Reducing machine downtimes due to maintenance and tool changes (availability >95%);

- Reducing the consumption of materials, energy and CO2 emissions by 50% (GREEN TECHNOLOGY Industry 5.0);

- Allowing the digital communication between production line and company system and remote diagnostic access (Industry 4.0);

- Flexibility in forging products of different sizes and materials (steel/brass/aluminium);

- Increasing the safety of the production line by reducing human intervention (industry 5.0).

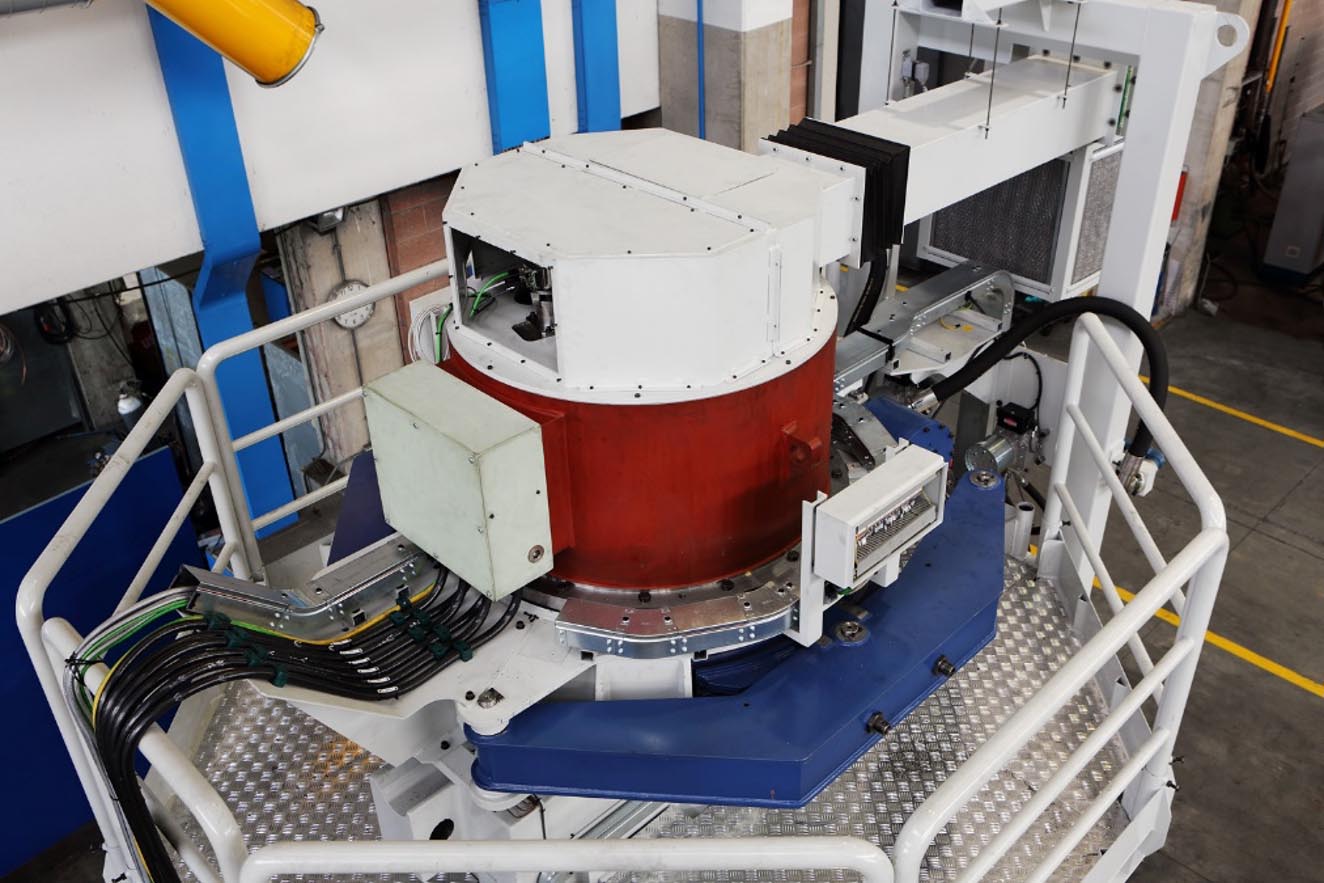

TDS Electrical Torque-Driven Screw presses

TDS Electrical Torque-Driven Screw presses result to be particularly suitable for the hot forging of parts destined to fashion sector.

Here below the 4 strong points that make many customers to prefer these hot forging screw presses:

- Cycle time does not dependent on forging energy => always optimized productivity

- Reduction of friction parts => less maintenance and less energy consumption

- Flexibility in energy settings => production flexibility for product size and type of material (brass, steel, aluminium) and reduction in dies wear

- Energy recovery of braking energy => reduction in energy consumption

Click on the image to enlarge

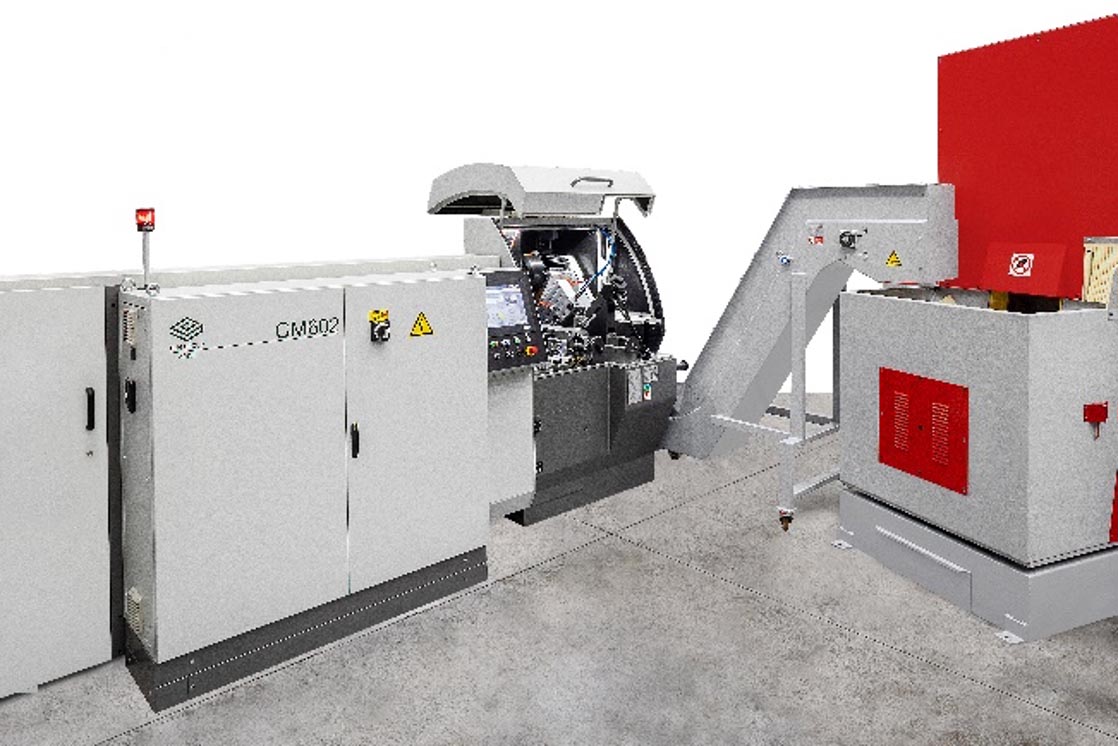

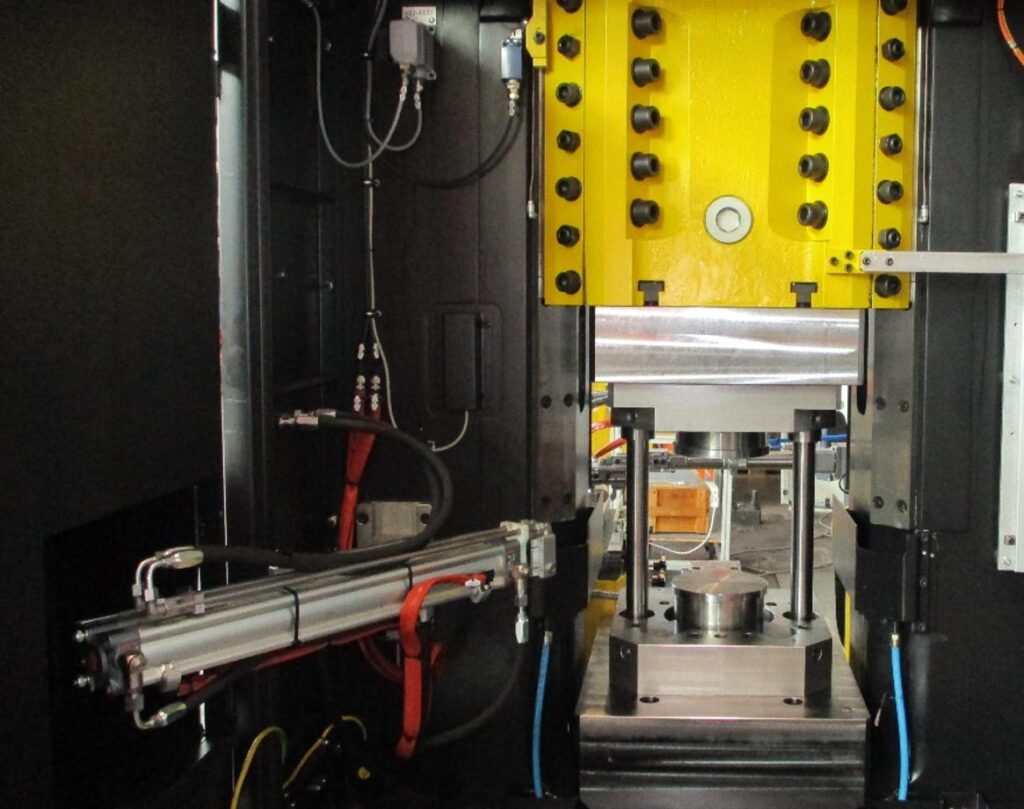

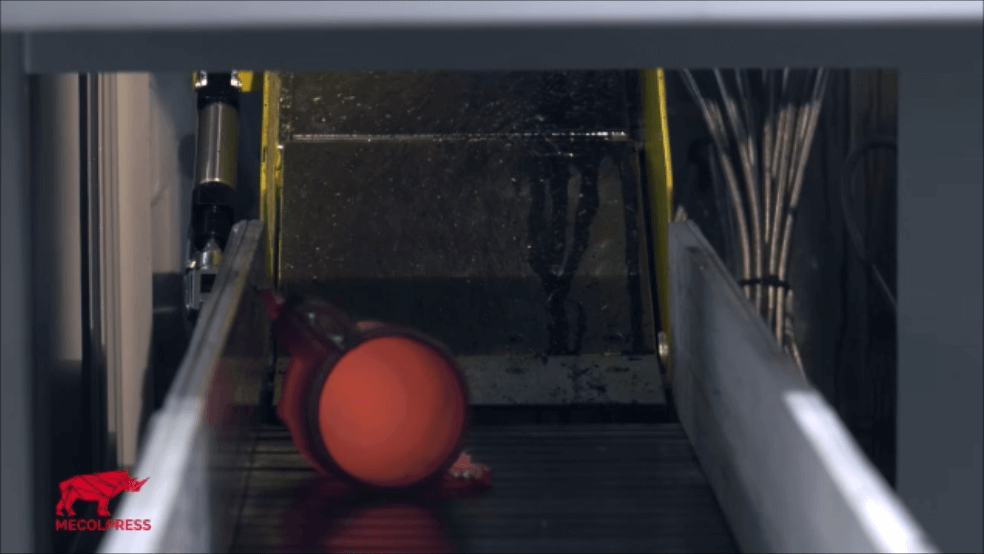

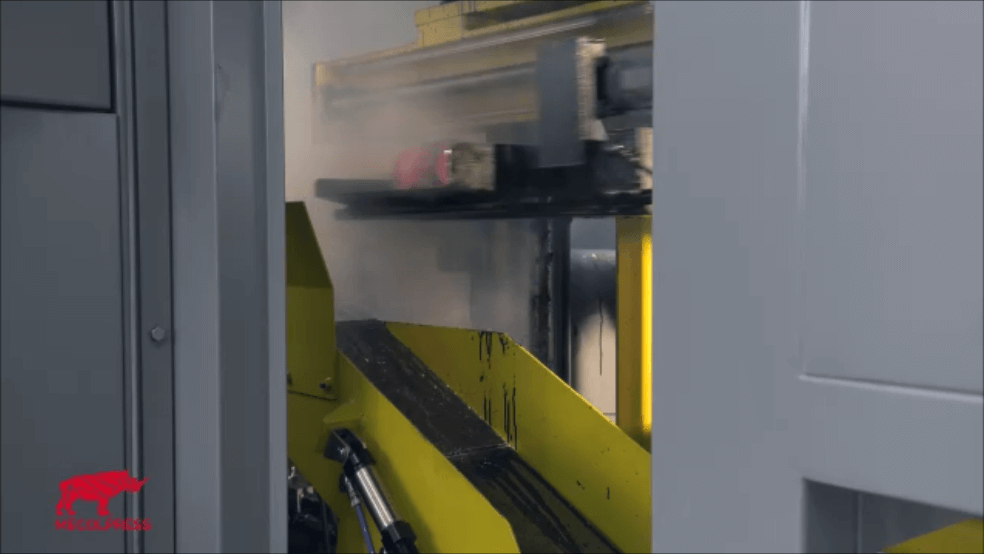

Complete forging lines integration

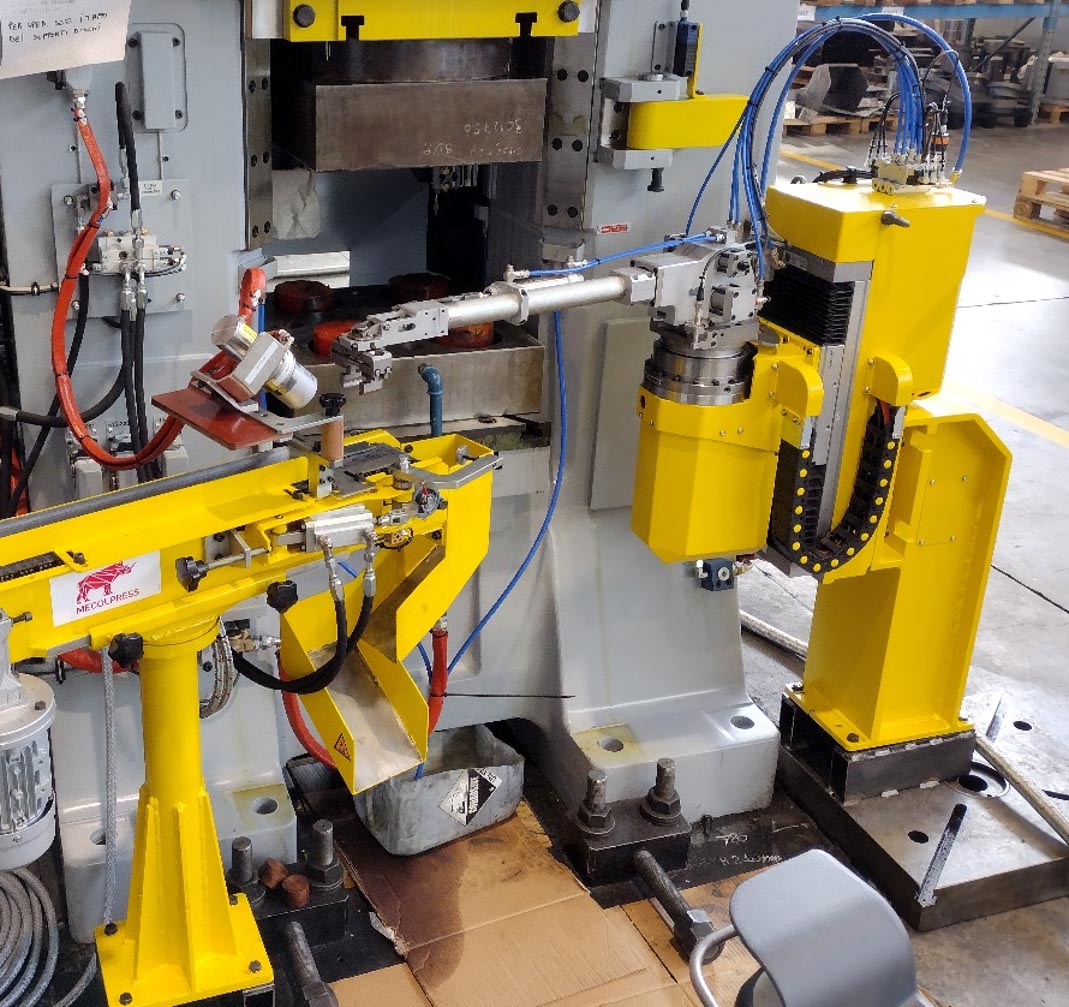

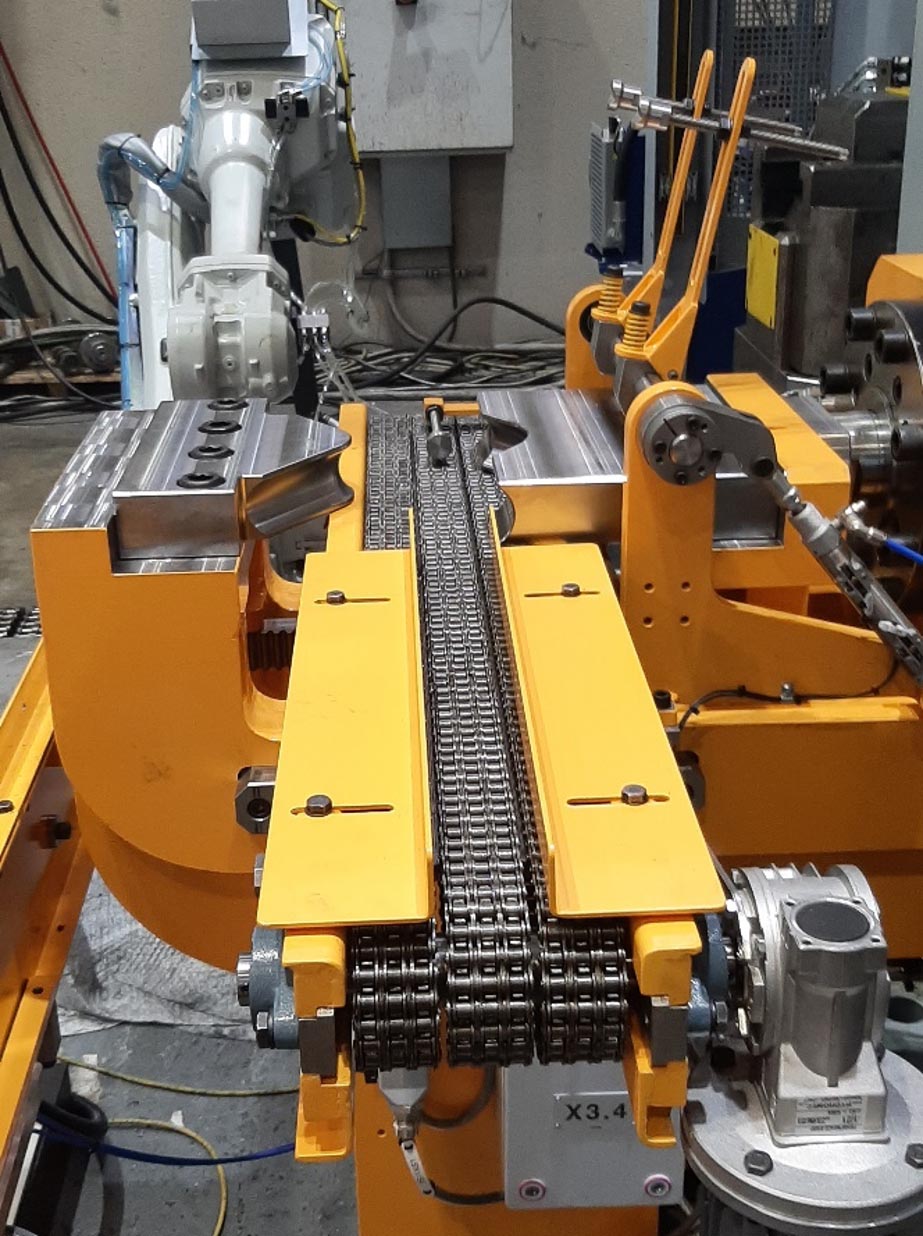

Even in the fashion sector, the frequent request is to have complete forging lines.

We can supply the line following the customer need, so in addition to the hot forging press, we integrate the cutting, heating, forging and deburring of the forged pieces.

Click on the image to enlarge

The presses for forging of parts destined to fashion sector have to optimize the process phases:

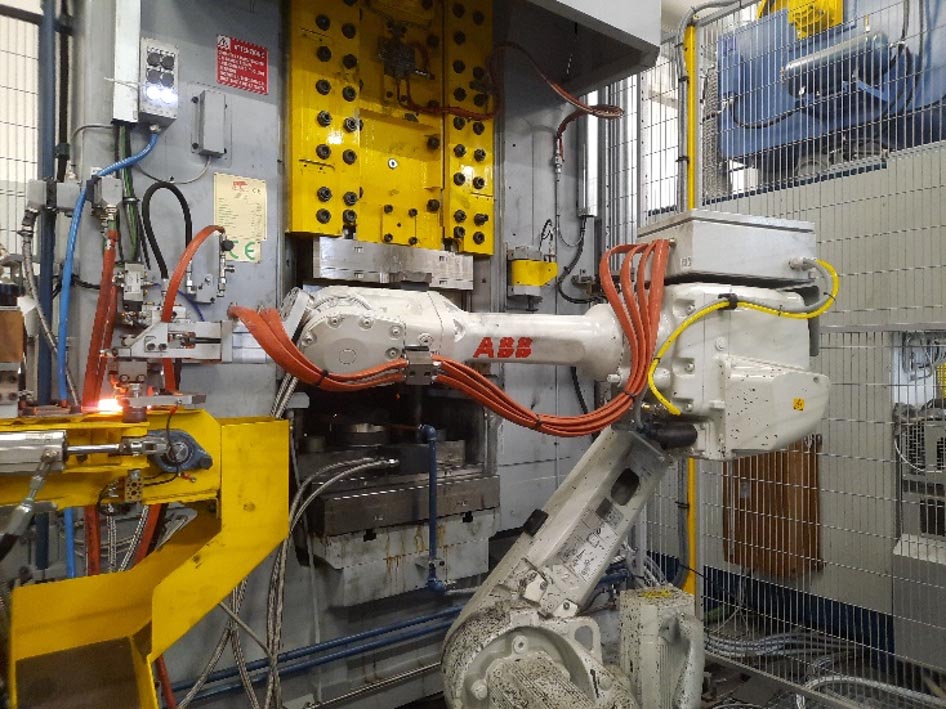

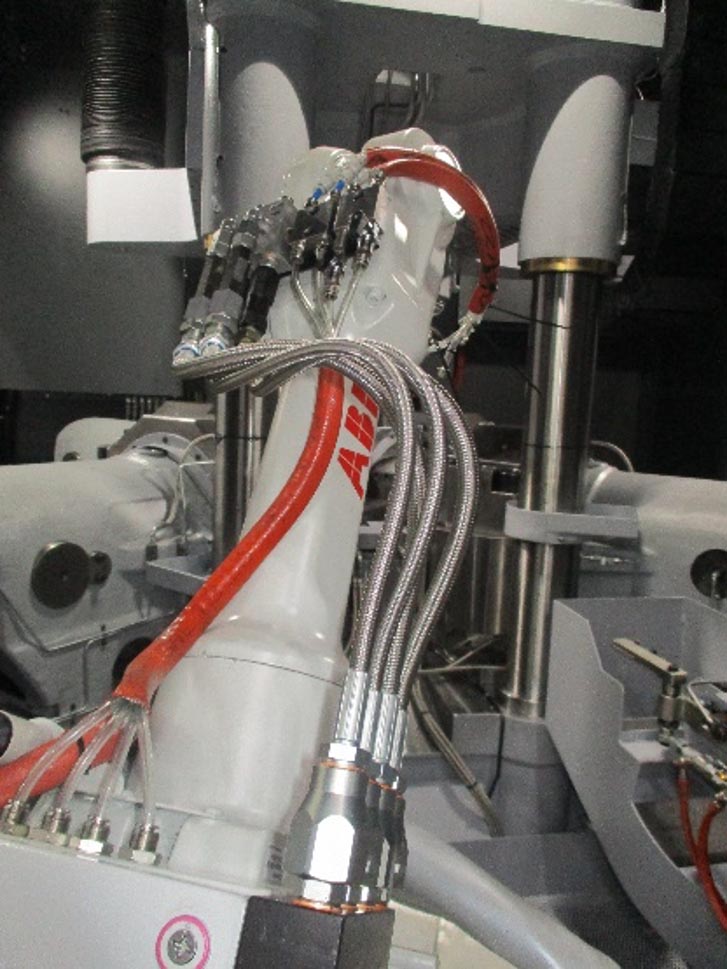

Automation of machine loading and unloading

We underlined the importance of automating the loading and unloading phases of pieces. The presses must include certain solutions to guarantee maximum performance:

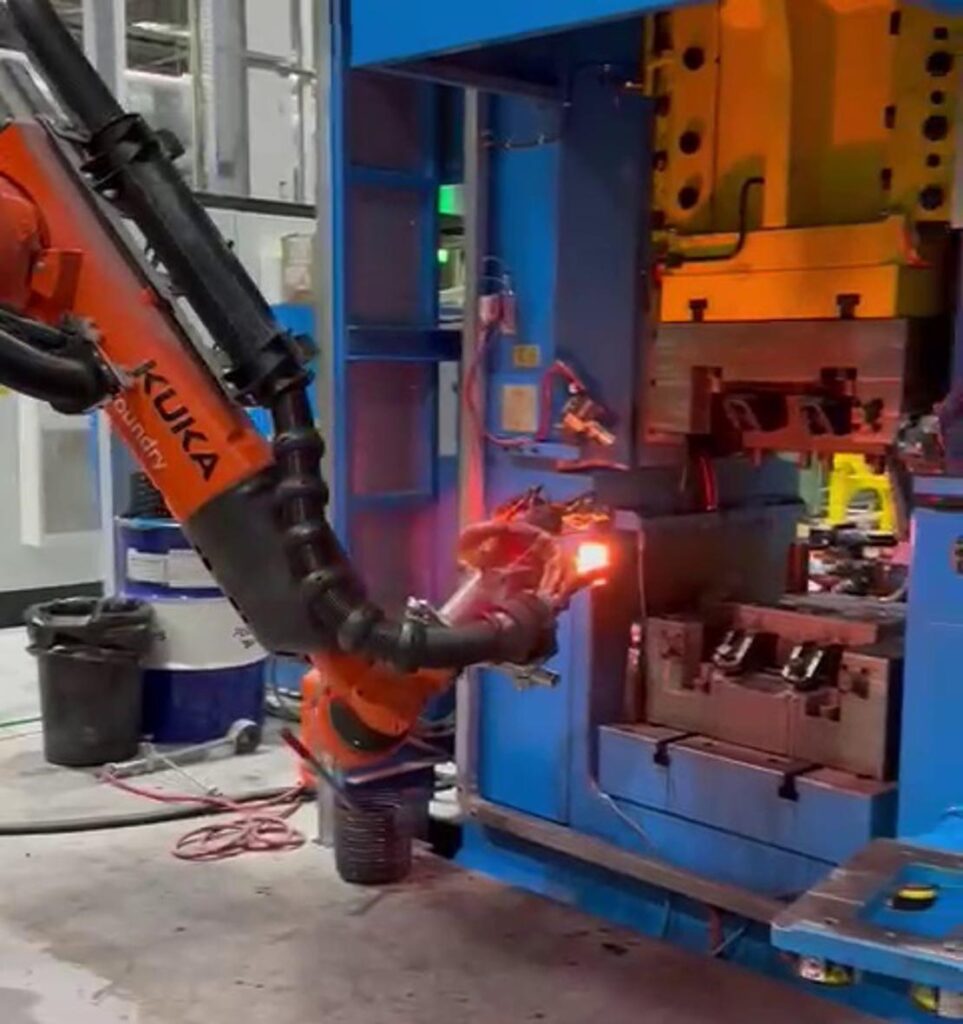

- High-speed Cartesian systems for heated material loading.

- Flexible anthropomorphic robots for heated material loading.

- Unloading of the forged product via air blow to avoid sliding and contact defects.

- Folding of the material to be forged to have a shape as close as possible to the forged parts and to reduce material consumption.

- Possibility of different shapes of the starting material from the traditional round billet to customized shapes (letters, symbols, …).

Click on the image to enlarge

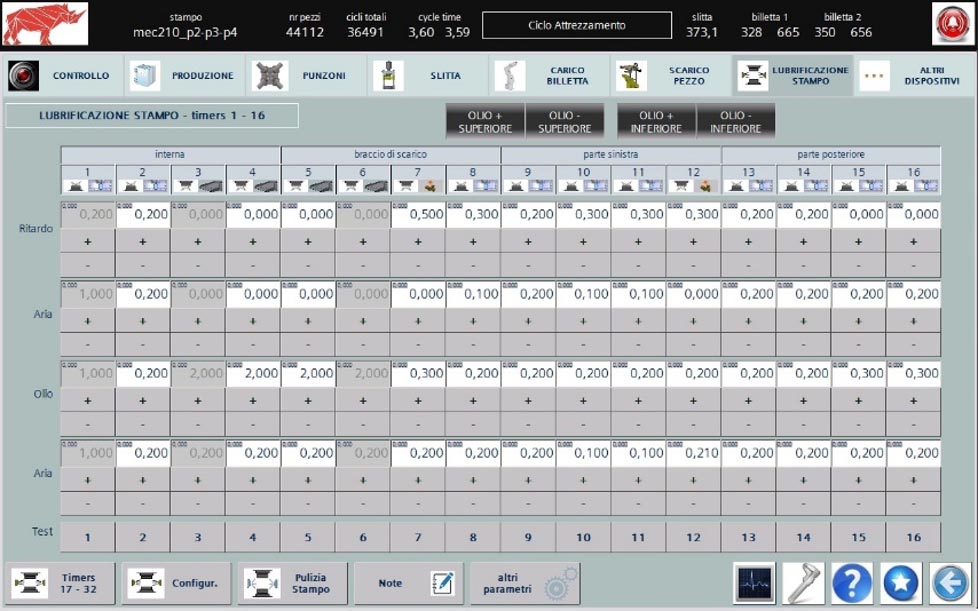

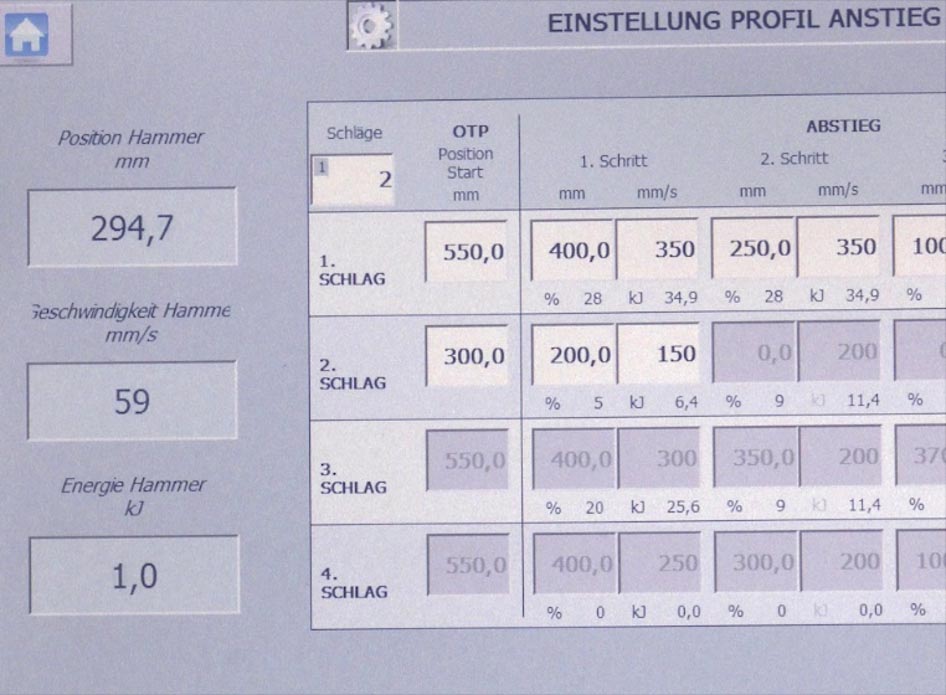

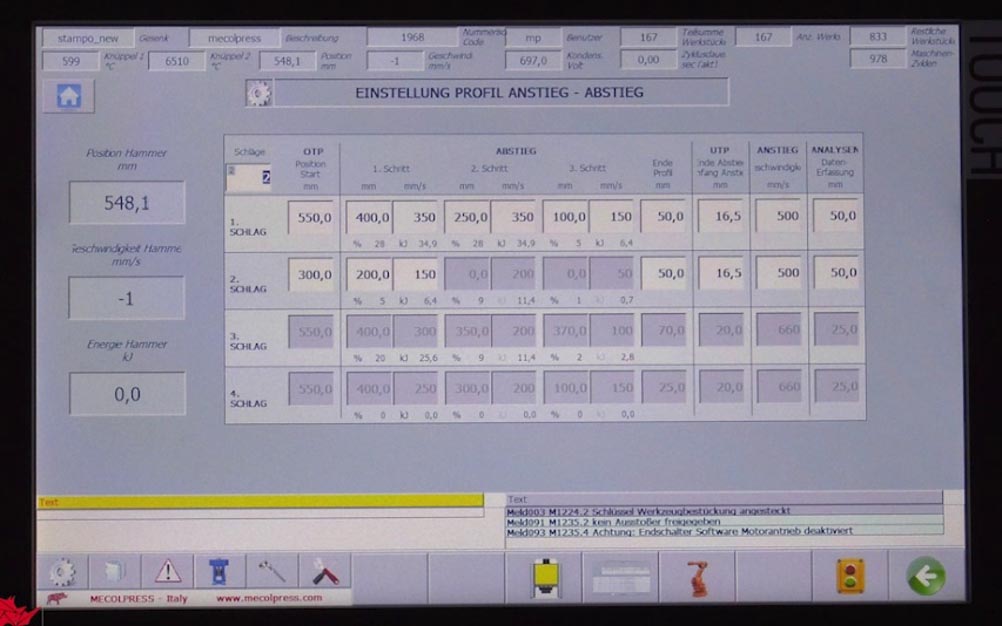

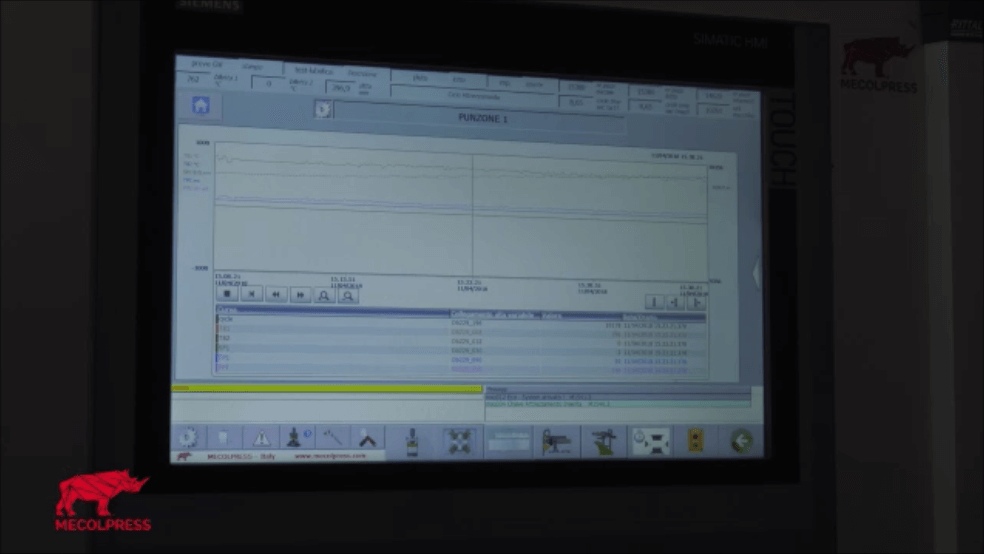

Productive process data control system

An important solution to take into consideration to start a successful hot forging project for parts in the fashion sector is certainly to equip yourself with a control system of the productive process.

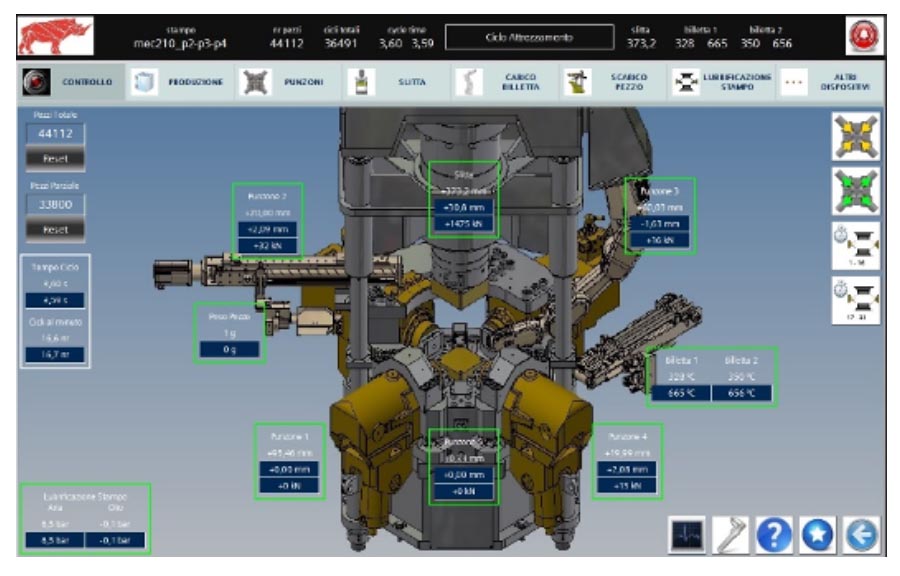

Mecolpress Calipso Software allows to monitor and to adjust the data connected to forging process, and it presents numerous advantages, among which:

- Based on HMI architecture complete with touch screen display

- Functioning parameters of the press and of the auxiliaries that can be inserted from the display.

- For each forging cycle, the main parameters are saved for collection and analysis.

- Integrable with company MES/MRP systems.

- Remote access for diagnostics and problems solving

Click on the image to enlarge

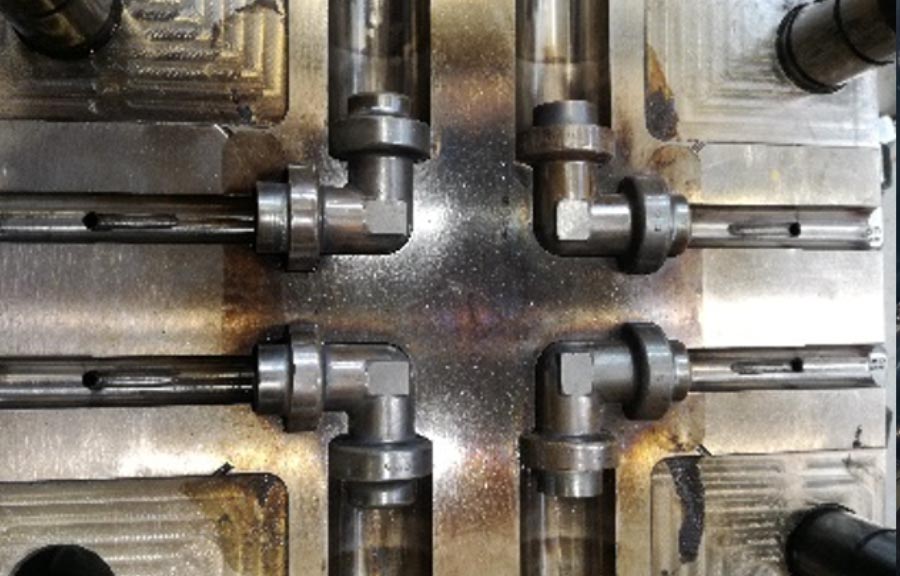

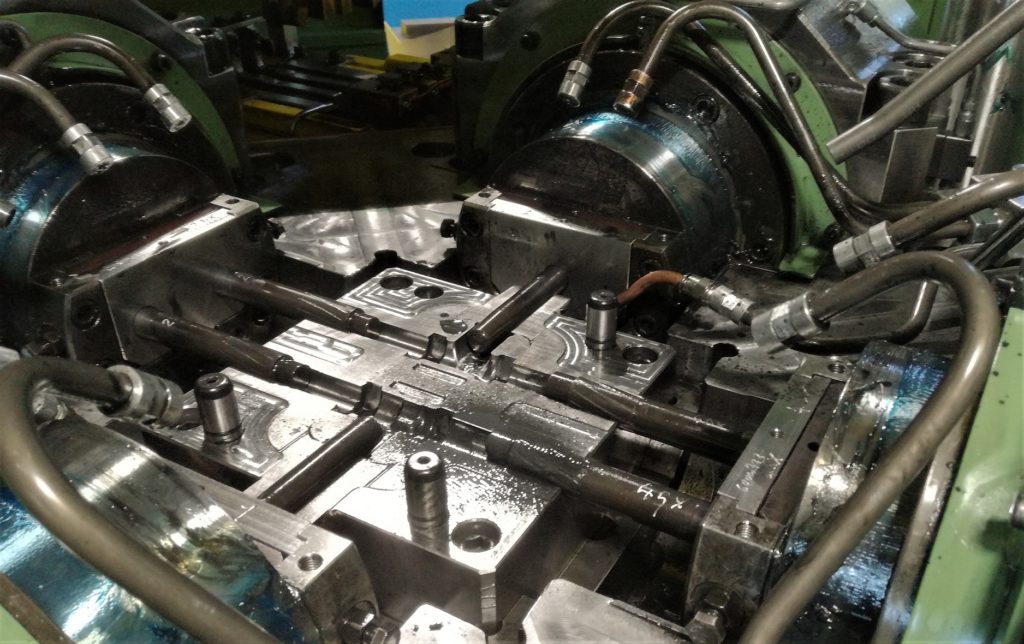

Dies lubrication

The proper dies lubrication makes the difference for a successful hot forging process.

A correct lubrication does not mean a lot of lubrication, but it must be properly dosed, the most suitable lubricants must be chosen based on the metal to be forged and the required piece.

We propose:

- Automatic air-oil lubrication unit managed by the control panel.

- Up to 30 lubrication points.

- Automated lubrication arm synchronized with the forging cycle.

Click on the image to enlarge

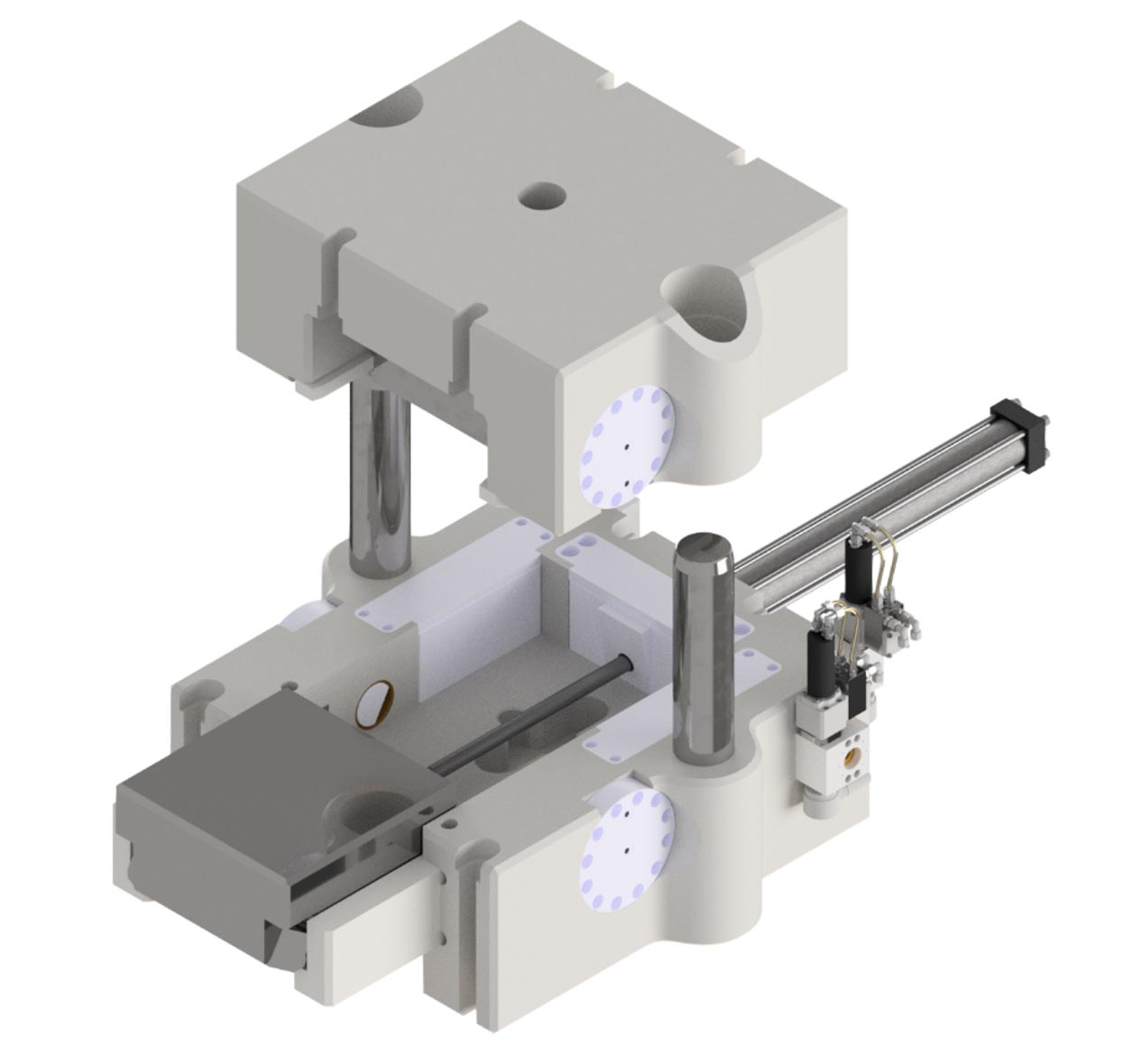

Dies changing system

To allow a quick unlocking, the die holder has been optimized, and the auxiliary arm becomes essential for bringing the dies out of the working area of the press.

Click on the image to enlarge

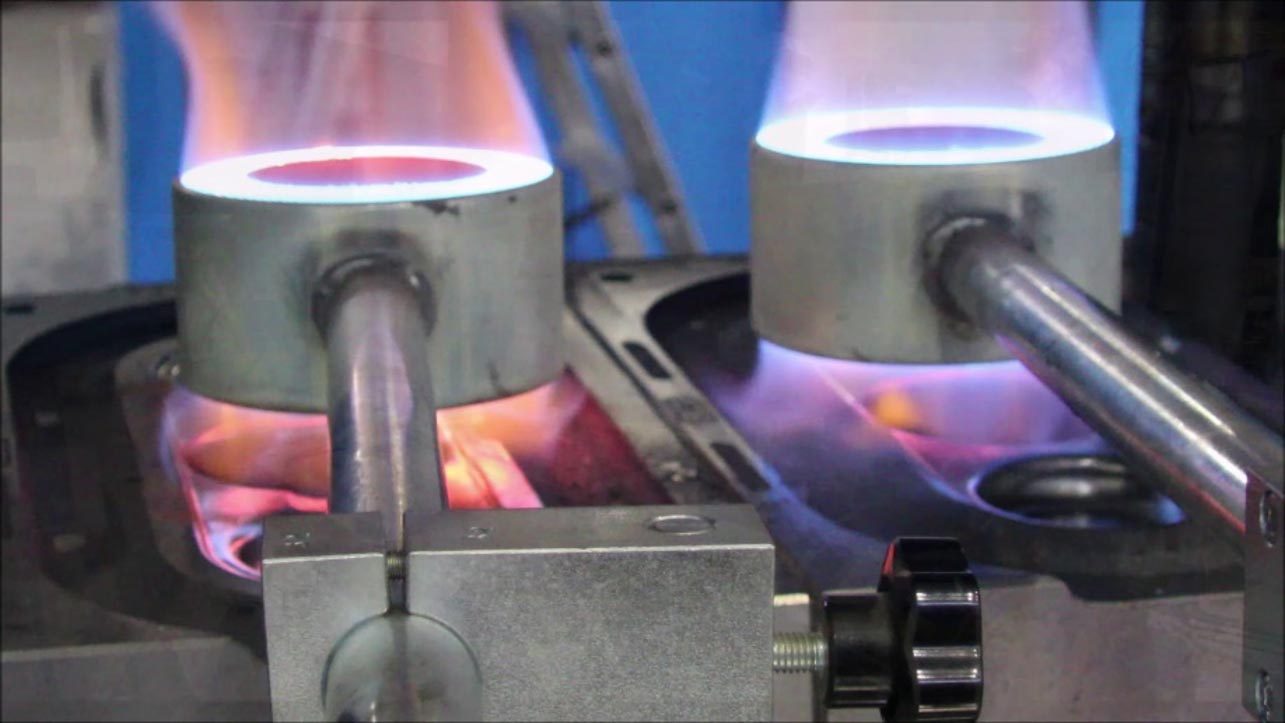

Dies pre-heating

This is an important phase of the hot forging productive process that foresees the use of modern induction technologies avoiding open flames or CO2 emissions.

In the fashion sector, therefore, hot forging presses and related devices are widely used.

It is always important to develop an accurate and successful forging project to maximize profits and reduce waste.

If the forging industrial process is stable and steady, it generates profit!

If the forging industrial process is stable and steady, it generates profit!

Today more than ever it is very important that the industrial process, in our case the hot forging one, remains stable and steady during operations time. As a matter of fact, by achieving this goal it is possible to generate profit.

The costs increase in raw materials, energy and specialized personnel is a more and more important and relevant constant for every manufacturing business. The profit of each order or job must always deal with these variables which can hardly be controlled.

The production stability can be controlled: the process must always be repeatable in the performances and must grant steady operative costs.

The metals hot forging is not an exception. Annual productions can reach tens of millions of pieces and each of these must be produced following the expected and planned parameters, the profit expectation must be guaranteed!

How is it possible to manage, monitor and correct tens of parameters, for millions of parts, granting the stability?

It is possible to grant the process stability even when millions of parts are produced and the process parameters are numerous, in this way:

01

=> monitoring the variability factors that influence each process to understand if they are under control or not by means of the statistical control.

02

=> Obtaining highest rigidities, forging force, and positioning precision.

03

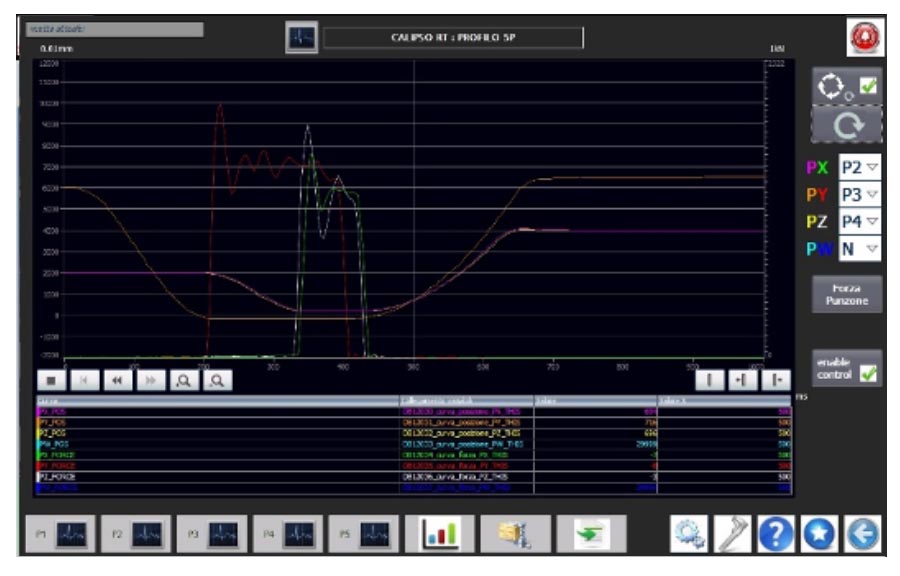

=> Real time check of the behaviour of the main process parameters.

04

=> Modification of the main forging values without interrupting the production.

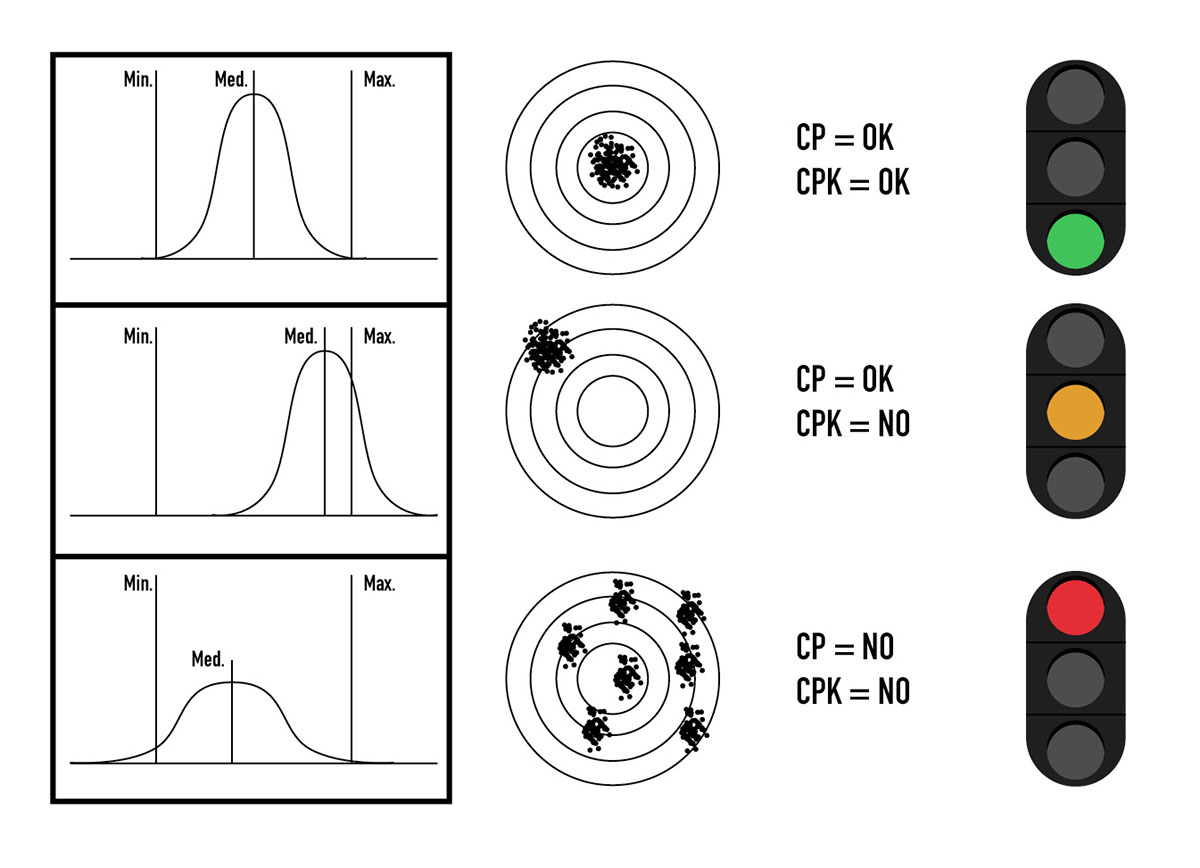

Statistics teaches that Cp and Cpk parameters are fundamental for controlling the progress of the forging process, for each variable in fact they are the key to understand its stability.

The example of the shooting with darts game allows you to quickly understand the concept:

a good Cp indicates that we are very repeatable in our shots, but it does not mean that we are hitting the target.

Only by obtaining a good Cpk, too, as a matter of fact, the optimal result is guaranteed!

=> Cp e Cpk must be much higher than one.

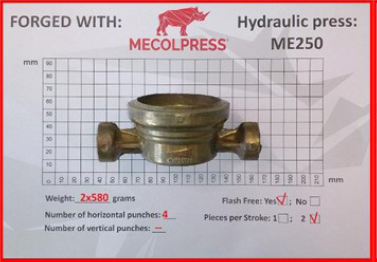

Let’s move on to a practical forging example:

-

Forging a batch of 25,000 water meters.

-

or forging a batch of 50,000 gas control valves

The dimensions of the forged parts are determined:

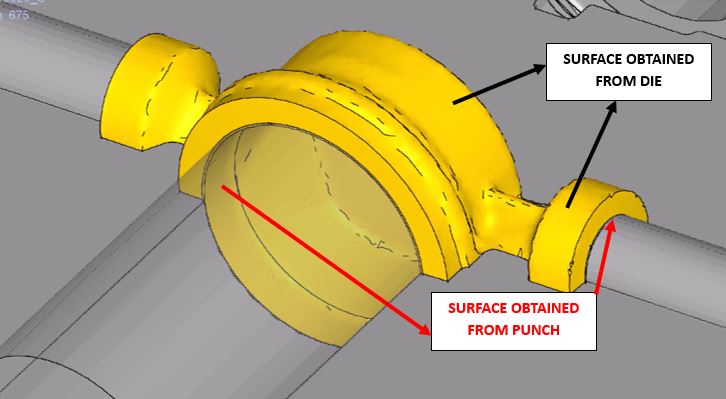

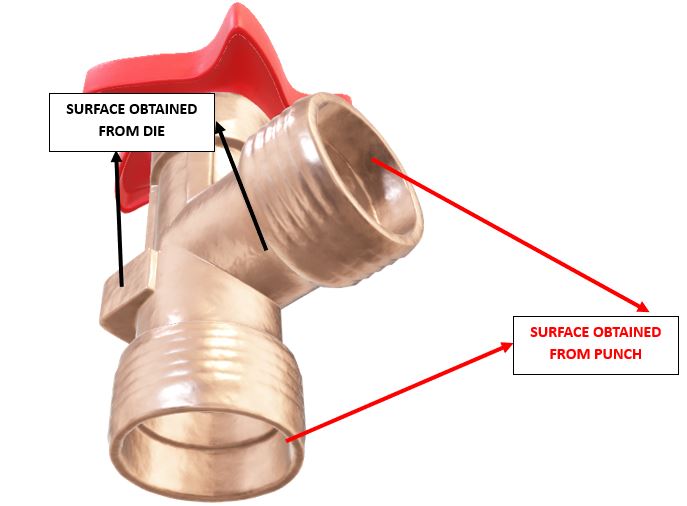

- by the surfaces of the part shape created in the die.

Cp depends on the presses rigidity performance and on the die design.

Cpk depends on the correct evaluation of the material shrinkage, which is related to the forging temperatures, to the part geometry and raw material chemical composition.

- by the punches involved in the material deformation.

Cp is obtained from punches rigidity and thrust force.

Cpk is obtained from the possibility to adjust the punch arrival position.

During the forging tests carried out with our customers from all over the world, the dimensional statistical analyses carried out on the produced samples (batches of thousands of pieces) have demonstrated that Cp and Cpk parameters were always abundantly and stably higher than one.

The complex geometries or the parts dimensions are not a problem.

How could we maintain the forging industrial process stable on our ME Hydraulic Presses?

- Mecolpress presses are equipped with Calipso software for operative parameters setting and their continuous control. Calipso, software entirely developed by Mecolpress, allows you to control the main process parameters in real time (forging forces, position, speed, …). Even before measuring the pieces, it is possible to understand if the forging process is stable and guarantees constant performance.

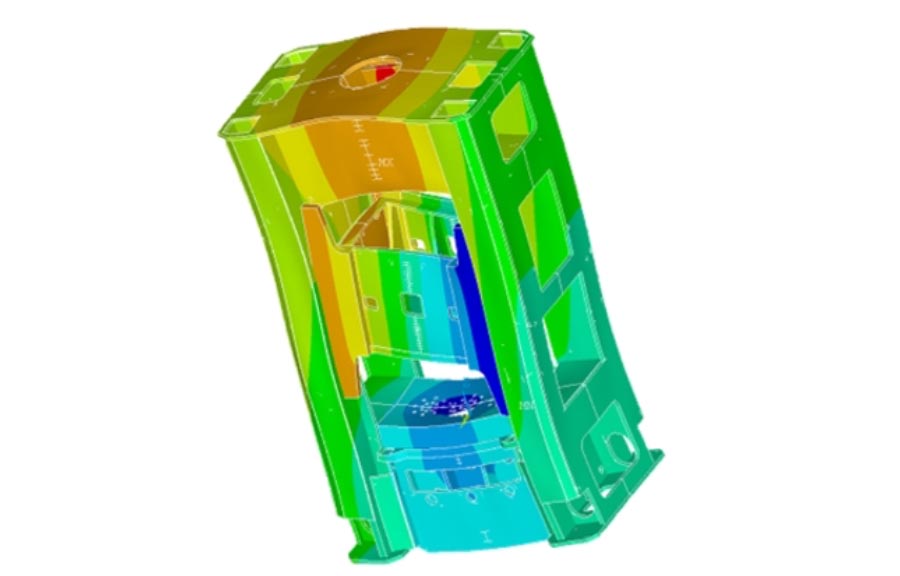

- Our presses are designed with advanced calculation systems (FEM) which allow to predict the rigidity of the components with the utmost precision, minimizing their deformations, even if subjected to high loads.

=> Cp under control

- We have designed our hot forging presses in order to have the highest possible dies closing force and maximum punch thrust force.

=> Cp under control

- The stroke adjustment of the individual punches occurs in real time, thus allowing the related dimensions to be modified during production.

=> Cp under control

- The long experience in dies design and the collaboration with the best specialized companies in the sector have allowed us to create the dies with extreme accuracy, in order to guarantee stable production of the pieces.

=> Cp under control

ME 350 NEXT GENERATION PRESS

ME 350 Next Generation Press: still the most powerful press, now it also minimizes the energy consumption.

ME350 press is the powerful of Mecolpress hydraulic presses: the latest version we have developed is able to grant a significant reduction in energy consumption.

Our goal is to make our customers more competitive in a very challenging market. The increase in the costs of raw materials and energy is not yet stabilized and a substantial reduction is not yet in sight. Our customers have to manage and deal with variables such as:

- product differentiation,

- the need to adapt to high volume production batches,

- managing frequent product changes,

- the difficulty of finding a stable workforce,

- the need to produce just in time,

- the increasingly high quality required of the forged product.

Mecolpress technological innovation starts from the challenges the market imposes on producers with the aim of overcoming them.

The new ME350 Next Generation press incorporates all the latest innovations:

01

Maximum dies closing force and maximum one of the independent extruder punches => flash-free forging and reduced thicknesses => reduction in raw material consumption (up to 40% compared to traditional forging).

02

Regenerative hydraulic circuit and adaptive power control to harmonize the energy consumption with the effective forging demand => reduction of electricity consumption (up to 50% compared to the presses of previous generation).

03

Anthropomorphic loading robot and quick dies changing system => increased flexibility by changing a product with another, reducing the necessary machine downtime.

04

Possibility of forging more parts each cycle in the shortest time, reaching the production of 5,000 pieces per hour => high-volume production batches are completed in a short time.

05

The production process is fully automated and connected to existing MES\ERP systems (Industry 4.0) => better staff management who can easily manage multiple presses simultaneously without stress.

06

CALIPSO Software checks the trend of the forging parameters (forces, displacements, sequences, ..) by comparing them with the references => any possible criticality on the quality of the product is overlined in real time and the part is separated from the correct ones.

All these innovations are added to Mecolpress long-lasting experience in the forging field, gained in the province of Brescia, a key area in the global panorama of the production of brass components. Mecolpress offers to the customers a vast availability of spare parts to minimize the relative delivery times and a team of specialized technicians to carry out assistance interventions all over the world.

Smart Brass Forging

We report the article below FIA Magazine, the Forging Industry Association, that speacks of us.

Smart Brass Forging

By Danilo Fagnani

MECOLPRESS started their activities in Brescia (Italy) more than 50 years ago, in 1969, providing solutions for the hot brass forging industry. MECOLPRESS then widened its portfolio including hot forging steel, aluminium, titanium, and special alloy applications. MECOLPRESS is now offering the most modern technologies available for mechanical (HEAVY family), hydraulic (ME Family) and screw driven (TDS, FPN family) presses.

The region of Brescia, located East of Milan, is generally considered the cradle of brass production, at least 20% of the total world production is firmly located here. The Brescia region is still able to compete with Chinese brass manufacturers (35% of the brass total world production) even if the production costs are not comparable in terms of manpower, energy and etc… The secret of this success is the know-how of the full brass production chain, industrially started from the 19th century, from melting process passing through forging then achieving the final product completion. MECOLPRESS was born and built in this interesting and dynamic environment, participating and contributing to solve the main challenges of brass producers (Smart Brass Forging).

These challenges are cyclically recurring in the market, and they can be summarized as follows:

- raw materials availability and costs;

- high variability in the market for parts from the peaks of high demand to small lots with frequent parts changeovers;

- difficulties to find the necessary manpower, from highly skilled operators, to maintenance technicians, to standard operations workers;

- availability to grant the best products quality reducing the non- compliant ones;

- reduction of the energy consumption approaching the green economy

MECOLPRESS is supplying to the market the most powerful hydraulic presses (ME family) offering horizontal\vertical coring performances achieving:

- flash-less forging;

- reduced part material thicknesses;

- deeper and deeper punch coring

These features drive achieving parts with less weight and avoiding any further downstream process as trimming. ME hydraulic presses family (more than 60 units supplied from 2010) has standard sizes:

- 100 to 500t as die closure force

- 30 to 350t of punch coring force

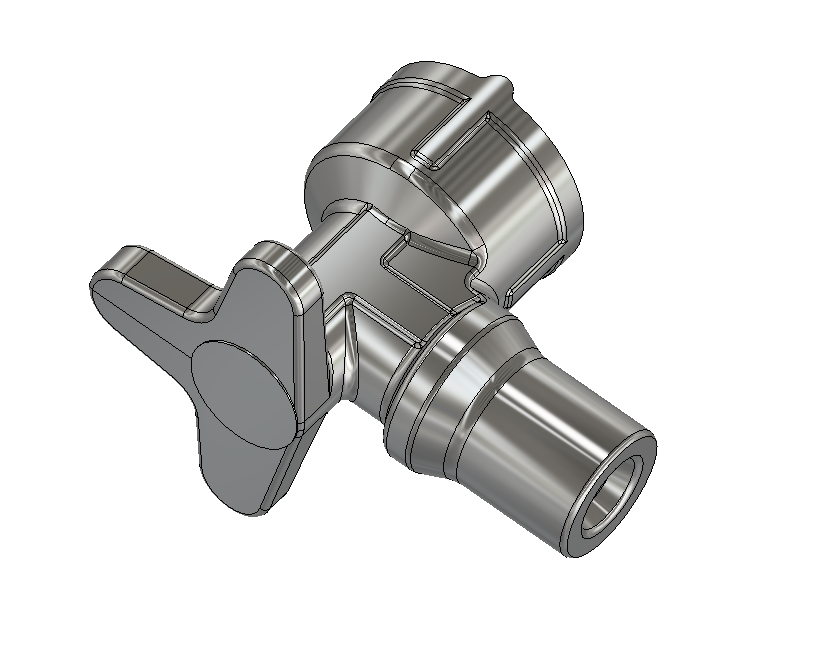

The coring punches have independent movement guiding and optimizing the flow of material inside the die’s cavity. The punches forces, speeds, displacement sequences can be flexibly implemented in the HMI operator panel depending by the products to be forged (Smart Brass Forging). One of the four horizontal punches can be orientable (without losing coring force!) with the variable angle from from 0 to 45° allowing sloping coring for the parts.

The ME family hydraulic presses grant production performances that, depending by the equipment size, can reach up to 30 cycles per minute and they allow to forge multiple parts per stroke, throughout of some thousands of parts per hour is easily achievable. This will allow to complete productions lots is shortest time even if they are relevant in the number of parts to be reached. If the market conditions are changing and the market moves to lower number of parts per lot with frequent shifting between the products, the quick dies changing system will allow to dramatically reduce the down time. The fully automatic tools locking\unlocking and the servo-moved supporting arms allow one operator to accomplish the change in the quickest time (about 15-20min), in the complete safety conditions and without the help of any tools (Smart Brass Forging).

Mecolpress ME Next Generation series hydraulic press hot forging EG coring tool

The MECOLPRESS policy to reserve relevant stock of spare parts for all the presses that have been supplied is a key point to avoid unwanted down time in case of maintenance of the equipment.

Mecolpress ME Next Generation series hydraulic press outstanding parts weight reduction

MECOLPRESS is developing all of the control software for the presses: CALIPSO (Smart Brass Forging). This user interface is based on a touch screen model, it is very easy and intuitive, and it has been developed in several different languages; it allows any end user operator to work with continuity on the press and it does not require any particular skills or knowledge. Many functions have been simplified as input parameter requests to reduce the human factor effect in the press working conditions. CALIPSO defines and controls automatically all the ME family presses operations, from raw material loading up to forged parts unloading. The main parameters of each product receipt are saved in the internal memory, and can be easily retrieved for future production and transferred to customer MES\MRP. The press has an Ethernet OPC-UA connection module that grants this function as well the remote teleservice assistance by the MECOLPRESS technicians.

The MECOLPRESS R&D department is able to define the optimized process parameters and/or the best die geometry through FEA software which allows them to analyze both material flow and forging force. This on-demand service is appreciated by customers who are searching for a reliable supplier.

ME hydraulic presses can be paired with all types of furnaces: billets, bars, natural gas, electric induction, keeping in mind that the reliability on the heating temperature, the billet weight tolerance and the material metallurgical microstructure properties are key parameters to grant effective flash-less process success.

High production capacity, flexibility to switch from one product to another and high equipment reliability vanish if the forging process is not under full control. CALIPSO software is leading the game supporting the customers to control, with minimal effort. The forging forces, punches displacement parameters and sequencies, billets temperature, and so on can be monitored in the maximum\ average values or continuously during the working cycle. The desired thresholds can be set in the system to monitor the trends of the parameters and if any mismatch is found, the parts can be diverted automatically to the dedicated collecting box for further checking.

MECOLPRESS is fully committed to be an effective part of the green transition of the industry, reducing the energy consumption, pollution emission, and media consumption. This application shall not decrease or compromise the outstanding powerful performances of the ME family presses. CALIPSO and in-house engineering are the main characters of this target:

- hydraulic auto-adaptive regenerative function circuits;

- ECO mode for working pressure optimization;

- actuators optimized geometry;

- flexible set up of the operating pressure;

- AC frequency converters\variable flow hydraulic pumps;

- CALIPSO software that learns from experience optimizes the working parameters without relevant operator required intervention (Smart Brass Forging)

Mecolpress ME Next Generation series hydraulic press main view

These points collaborate to reduce the energetic consumption up to 50% in comparison with standard technology presses.

The dies lubrication system, very important in the flash-less forging, is using innovative pipe to pipe technology supplying alternative air and oil flows just with the needed quantities. All the dies lubrication parameters are set into the control software and up to 30 points can be reached; they can be integrated into the dies or with external nozzles. The proper pumps are installed on the machine bottom to collect all the remaining quantity of oil avoiding any overflow. The press lubrication is selective and only the components active are reached by the media, proper collecting box avoid leaking. No more waste of fluids!

Pressa idraulica Mecolpress ME Next Generation: esempi di particolari stampati a caldo senza bava

Mecolpress ME Next Generation series hydraulic press four parts flash less hot forging examples

The innovative suction hood embedded in the press structure collects the emission very close to the sourcing point, decreasing any possible spread into the environment and granting the best cabinet inside view of the process to the operators.

As all MECOLPRESS products, the ME series fulfills the most severe international safety standards and can be produced in compliance with North American and Canadian ones.

Danilo Fagnani Sales Manager Mecolpress

Danilo Fagnani Sales Manager Mecolpress Spa

Phone: +39-030-2560110

Email: d.fagnani@mecolpress.com

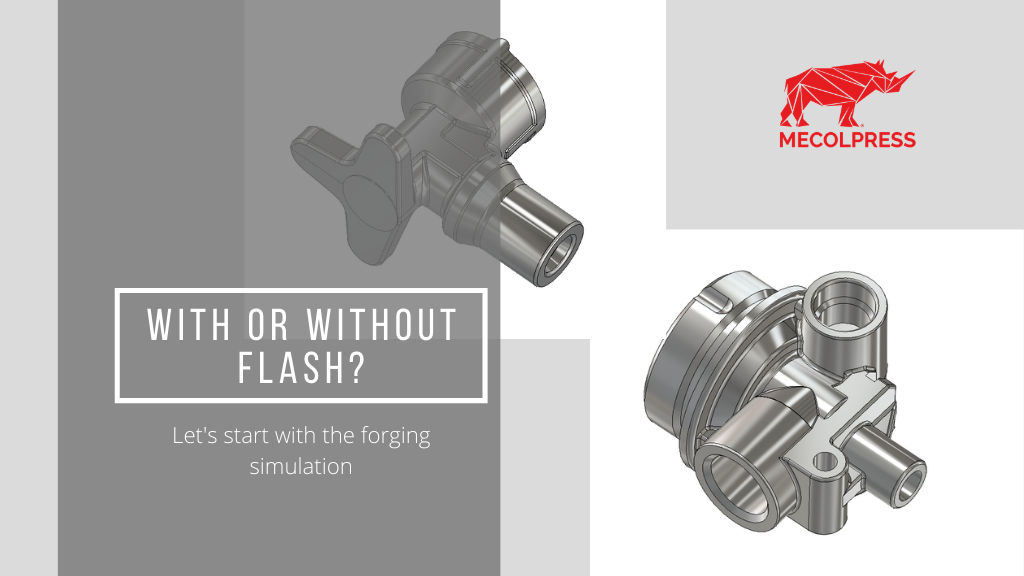

With or without flash?

When you have to face a forging project for a new piece, the first step to take is to make a simulation by means of forging software and to decide whether to set the simulation with or without flash.

With or without flash?

Start with the forging simulation

In general terms we can affirm that thin-thickness pieces and material movements in different directions or with sudden dimension changes can give defects in flash free forging.

If the geometry is uniform and the section variations are contained, you can think of dealing with a flash free project.

It is true in all cases that starting a flash free project can allow evaluations that push to optimize the geometries of the piece (if it is possible to operate on the outer geometry) or it can drive the next analysis with flash.

A first flash free step involves certainly reduced calculation times and allows an evaluation of the punches forces and dies closure that can approximatively be considered valid in general.

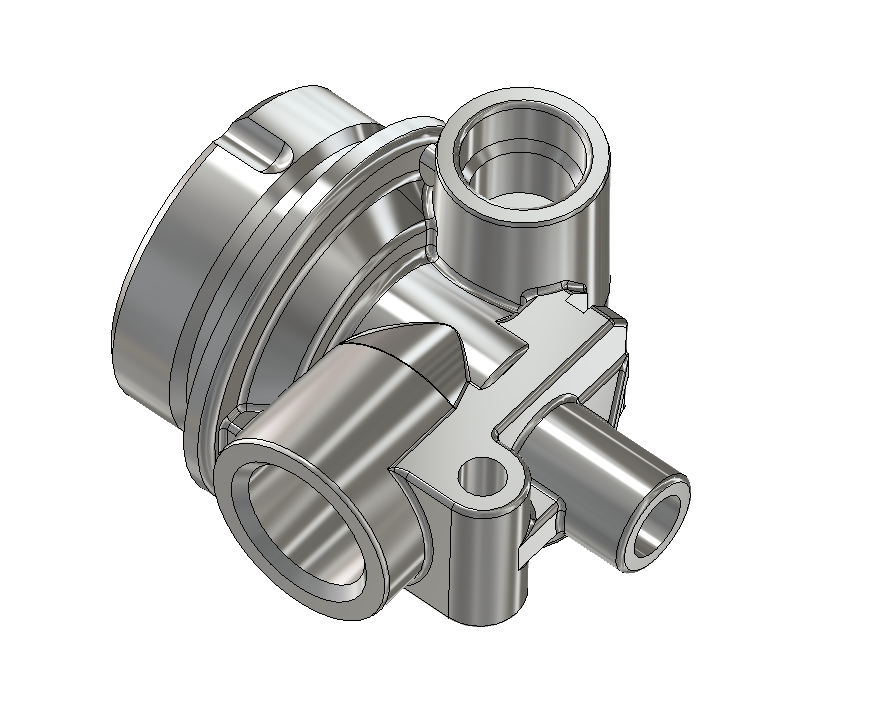

Suitable for forging with flash

Here above a geometry that very hardly is fit for a flash free forging

Suitable for flash-free forging

In this case, the success of a flash free project is very likely.

Is the press you have chosen suitable for forging your piece?

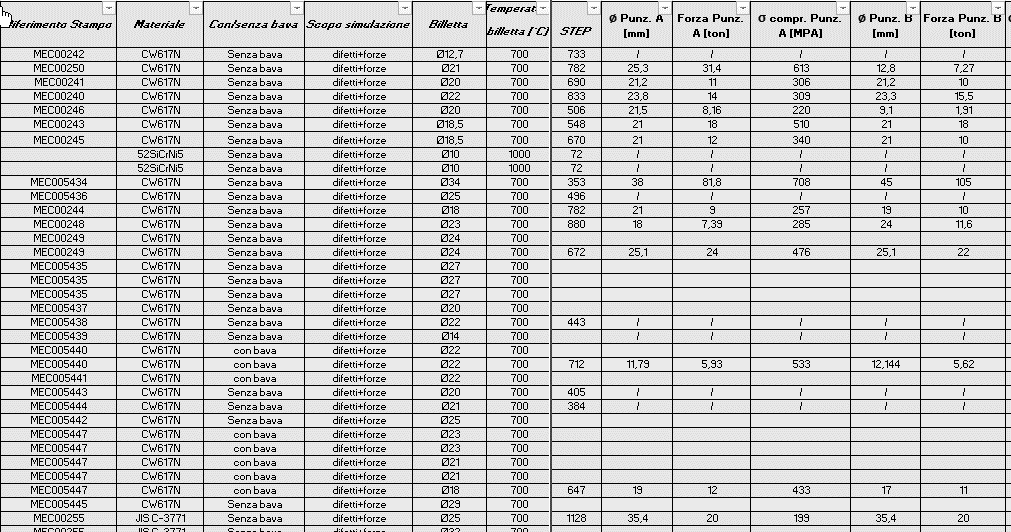

Secondly, it is necessary to roughly estimate if the analyzed piece is workable for the considered machine model.

At this stage you need to have a database showing the average pressures on half dies and on punches.

For this purpose, as the simulation history evolves, it is very useful to keep an Excel file in which the results in terms of forces are summarized in average pressures on half dies and punches.

This procedure allows you to understand at a glance if the result of a simulation can be considered valid or may be affected by calculation errors. Obviously, more cases are available more is likely to have reliable results, because the geometry of the piece strongly affects the force on each element of the die and therefore in the evaluation it is necessary to consider pieces with similar morphological characteristics.

Once the geometry of the piece is drawn, including the desired corings, it is necessary to obtain by subtraction the geometry of die and punches.

Firstly, however, the shape has to be scaled to take into consideration the fact that the formation occurs at a high temperature, while the drawing dimensions are valid for pieces at ambient temperature.

The typical brass value for forging is 1.012, while in the case of aluminum the factor 1.010 is generally used. With an Excel sheet, you can therefore estimate the diameter and length of the billet of first attempt.

For flash-free forging choose the hydraulic presses

Mecolpress hydraulic presses of ME series are the best solution for the forging of a part of brass, aluminum, or of other materials, without flash.

The closing force of the dies, higher than the one of the traditional mechanical presses, and the independent and controlled movement of the ram and of the extruders allow the hot forging of even complex parts without flash.

ME hydraulic presses have proved to be unbeatable in the forging of parts having some complexities.

For example, if you have to forge gate valves, our ME presses allow to forge these valves totally without flash, with very high precision, without the risk of defects caused by brass flow in the die.

In addition, even the production is higher compared to the one allowed by the traditional method with eccentric mechanical presses and with bell tool.

A ME350-4G240 hydraulic press, for example, can forge two-inch gate vales without flash, without the help of special tools, and with a productivity of about 800 parts/hour.

Another significant and practical example is that with a ME hydraulic press you can hot forge 4 brass parts at a time without flash!

Biography of our hot forging blog

At the beginning of 2017 Mecolpress decided to start a blog entirely devoted to the hot forging world.

We set for it 2 goals:

- Being a reference point for hot forging companies, above all if these are first-time forgers.

- Supporting the companies having a long hot forging experience but that want to optimize their process, to better use their presses and to find answers to the necessities they meet step by step.

We have realized, doing some internet researches that it is very difficult to gather information regarding the hot forging world.

On Google you can find anything, but you will barely find suggestions or detailed deepening on hot forging!

Frequently we happen to be contacted by beginner hot forging companies, or companies having inexpert or not particularly qualified personnel (for example you can read this article) and all of these want to have further information.

We are aware that it is not possible to become expert forgers or to learn a job from Google but it is equally true that in 2020 I have to find answers on the internet to my necessities and some deepening on the topic.

Who are we?

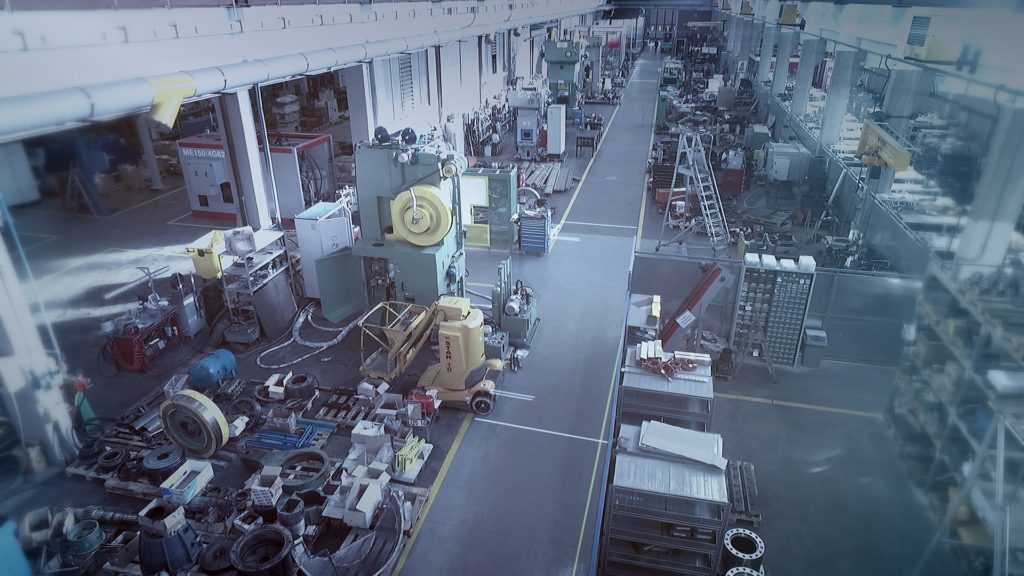

Mecolpress is a company specialized in the production and installation of hot forging presses for brass, aluminum, copper, titanium, steel and other alloys.

Mecolpress was established in 1969, therefore we have a long forging experience and knowledge.

In our production workshop we have persons extremely expert in brass hot forging, and recently we have inserted in our staff also a steel “technologist”, we have available a mechanic and electronic technical office completely internal and a highly appreciated customer-care service.

To date we have developed and installed more than 1.950 presses at more than 400 customers all over the world, used for the forging of brass, aluminum, copper, titanium and steel.

One of the features that our customers usually appreciate most is the after sales service: the great and guaranteed material availability is added to the expertise and solid knowledge of the machines. The efficient feedback of Mecolpress lies in the largeness of the areas dedicated to the storage of parts that can be requested by the customers (we have 2 devoted warehouses) and in the investments decided exactly in favour of the “warehouse”.

Why writing a blog regarding hot forging?

At this point we said “why not sharing part of our skills online? For example, with a company from South Africa that is wondering if it’s worth it to convert his production in a hot forging system?”

“And in addition, could all the expert forgers (Mecolpress customer or not) be interested to understand if there are improvements to apply to their production? The world has changed and even fields such as the hot forging one may seem as more “static” but, as a matter of fact, they are not. If you don’t stay up to date you will lose important commissions and the quality of your work won’t evolve!

Which kind of answers will you find on this blog?

With our blog we offer ideas and tips to improve each forging process. To manage the machines and the forging lines in the best way in order to obtain the best productivity, more flexibility and less maintenance.

The topics that according to us are easier to speak on are the technical ones, thanks to the experience acquired in 50 years of activity and to our numbers, but we try to maintain a character that can be easily understood also to the less experienced companies, remaining at disposal for further in-depth detailed explanation.

In the “Case Study” category you will find for example:

- How we could help a German customer of ours to win successfully a challenge, to forge a very complex set of parts that he didn’t dare to accept as an order.

- Is it possible to reduce the gate valves costs by forging without flash? It is possible by means of ME hydraulic presses.

- Is your screw press driving you crazy? You could have disregarded what for you is just a detail, but our experience taught us that it can make the difference!

We propose solutions to problems caused by a not optimal usage of the presses or screw presses, by the inexperience; these are requests that we collect from our after-sales department. We give voice to necessities that also for expertised hot forging companies sometime can appear as complex.

A challenge we can win for our customer means for us a great satisfaction!

The dies lubrication determines your forging success!

Knowing to take advantage of the correct dies lubrication is crucial in a hot forging system of brass, steel, aluminum, titanium or copper parts.

We have already highlighted many times in our previous articles how the lubrication can make the difference and solve many of the common problems that the forgers observe during the production of their forged parts. Our research of the perfect lubrication has evolved, becoming more and more precise and customizable, exactly like we are constantly required by the market.

A correct lubrication doesn’t mean that it must be of large quantity, but that it must be correctly dosed and the most appropriate lubricants must be chosen according to the metal types and required part to be forged.

The dies lubrication system of hydraulic presses of ME series and of eccentric press at continuous cycle of HEAVY series

With the hydraulic presses of ME series and the mechanical eccentric at continuous cycle presses of HEAVY series we have revolutionized the dies lubrication system:

- We drag the outgoing oil+graphite mixture on the lubrication point.

- We let the lubrication liquid and the compressed air flow in two concentric tubes of the control valves of the single points up to the usage point.

- For each of the points the pilot is independent and therefore for each of them we give the possibility to the user to choose from the operator panel how, when and how often to intervene.

But we were not satisfied yet!

Which are the requests the forgers most frequently address to us?

We have verified that some of the questions you ask our service department are regarding the lubrication system:

“My die has broken, what can I do to guarantee it a long-lasting life?”

“The dies lubrication system I am using is not satisfying.”

“Is it possible to reduce the waste of lubricants, in view of an even more ecological choice?”

“How can I obtain a successful forging system?”

Our Research and Development team has therefore perfected and developed a new lubrication system.

What’s new in the lubrication system of the HEAVY series

Heavy series is our new proposal of a mechanical eccentric at continuous cycle press. It is a very revolutionary machine, the result of 50 years of experience in the hot forging presses production, and of the continuous search for innovation and technology perfection.

As a result, we have completely reviewed even the automation and the dies lubrication.

First of all, the dies lubrication system allows for each single point the independent and programmable management.

It is possible to start the lubrication cycle in different ways: during the ascent or descent of the ram, during the loading or unloading cycle, with appropriate delay and duration times.

Each point can be used for the nebulization of the lubricant or for the cooling and cleaning of the dies.

The system can be implemented with 2 or more high capacity air blowing points.

It is possible to program the schedules: the pumping circuit, the automatic mixer and the heating resistance placed in the tank allow to prepare the liquid and the entire circuit for the starting time at optimal conditions.

The nebulization of the lubricant, thanks to the particular pipe system, is obtained only in proximity of the usage area: in this way the dosage, repeatability and the sensibility to the dosage variation are guaranteed.

40 lubrication/cooling points are foreseen, of which 16 are placed in the lower dies-holder and 16 in the upper dies-holder. The disposition of the lubrication/cooling points throughout the dies allows to reach efficaciously the critical points to be lubricated/cooled, in addition to drastically reduce the times of production change.

Reactive, smart system for creating your recipes

The responsiveness to the settings variations is immediate, unlike the traditional system that requires several minutes of production before it stabilizes.

In addition to this, we can have a strong blowing without the help of compressors (that are contributing to increase the consumptions and the general maintenances of the plant).

A smart software system helps moreover the operator to adapt automatically the dosage of the lubricant in the startup phase of the production, till to reach the correct forging conditions.

Our system can be adapted even to the use of lubricant/water-base release agent, e.g. used in the aluminum sector, that are different from the classic graphitized oil.

All the parameters, activation of the used points, start modalities, timers and counters, once they have been optimized, are saved in the recipe devoted to the type of the part to be produced, in order that for the following batches of the same article there is a fast production start without useless waste of time.

THE PRESS AUTOMATICALLY SEPARATES THE FORGED PARTS: GOOD IN ONE BOX, BAD IN ANOTHER!

Differentiated unloading of the forged pieces

The press automatically separates the forged parts and divide them into different boxes. The press has become intelligent!

The differentiated unloading of the forged parts is an interesting function that Mecolpress provides by default on all hydraulic presses, but it can also be added as an option on eccentric mechanical presses.

Hot forging for higher quality of forged parts

The metal hot forging differs from the cold one because it allows you to obtain high quality pieces through an important deformation of the starting material. By working brass, copper, titanium, steel and aluminium by means of hot forging presses, in fact, it is possible to produce particular shapes, even with complex geometries.

The metal hot forging therefore allows to obtain parts that are more resistant than those obtained through other production processes.

In particular, metal hot forging can increase the strength and resistance of the products. For these reasons, the production of hot forged pieces guarantees specific advantages in their mechanical characteristics compared to those produced with other technologies such as casting or mechanical machining with chip removal.

The hot forging, compared to the casting processes, allows to obtain mechanical characteristics and surface appearance of superior quality. We at Mecolpress know it well, so much that we have made “Technology of Shape” our motto.

The piece produced must therefore be perfect, its quality must be certified. For this reason, Mecolpress has designed a system that allows the press automatically separates the perfect forged parts from those to be evaluated as they may not be such.

Why is it so important that the press separates the perfect forged parts from those to be evaluated?

From the automotive sector, the Lean production method teach us:

- Companies can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

- The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

One of the most recurring needs in our customers is to have an ever more intense control of the forging process: the machine must be able to control as many parameters as possible important for the forging process, record them to make statistical predictions on the deviation from the optimal production, carry out checks.

Mecolpress offers a series of forging presses that fully meet the needs described above: the ME hydraulic series.

The hydraulic presses can control numerous process parameters and on these manage the logic for rejects or collect the measured values for statistical analysis. For example, they can control:

- the temperature of the billets to be loaded,

- the coring punches penetration time,

- the punches real penetration force,

- the final position reached by each punch.

Here you can learn more about the most important process parameters that hydraulic presses are able to evaluate.

The machines of the ME series have the credentials to be competitive in a modern and controlled forging field; they operate at their best on medium / small batches, thanks to their flexibility.

In this video we show how our hydraulic presses perform the differentiated unloading of the forged parts:

The pieces that do not fully comply with the process parameters set by the operator and analysed by our powerful Calipso software to control the forging process, are unloaded in a separate bin.

For the customer this operation translates into an important saving method:

- Less waste of time,

- Less material / pieces to be discarded,

- Be sure that the forged piece complies with the required characteristics,

- Get perfect shapes.

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!

Mecolpress, 50 years in the hot forging sector

This year Mecolpress has reached the goal of its first half century of activity by presenting a new continuous and discontinuous cycle press at EMO exhibition in Hannover, held last September.

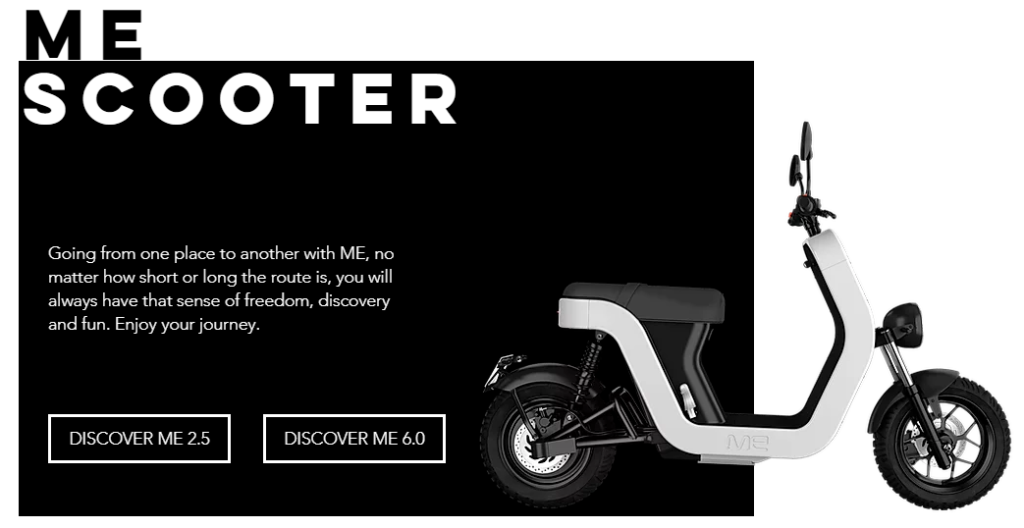

In the present of Mecolpress there is also an investment in the world of electric scooters.

The video story by the management of Mecolpress:

Established in 1969 by Giulio Molinari, Giulio Barbisoni and Pietro Caggioli, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. A few years later, in 1973, the company acquired its current production site in Flero, in via Don Maestrini, initially extended over an area of 2,000 square meters, and then it expanded increasingly reaching 6,000 square meters in 1993. Today Mecolpress has acquired a second industrial area next to the first one where the construction of a warehouse is coming to an end, reaching a total area of 30,000 square meters.

In addition to the industrial area expansion, over the years Mecolpress has aimed higher and higher thanks to the acquisition of two important brands of the screw presses production: the Italian company, Dellavia (1993) and the Swiss company, Osterwalder (1998). The company has always distinguished itself as an avant-garde reality in the forging sector: remarkable are the production of the first continuous cycle mechanical press in 1983, the production of the first continuous cycle electronic press in 1993, the design and construction of the hydraulic press for hot forging of brass components without flash in 2008 and the presentation on the market of the screw press with direct drive motor in 2013.

In September of this year, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

This new machine has an innovative and modern structure, more robust, and designed to simplify the control and maintenance for the operator. The automation and the dies lubrication of the machine was completely renewed, thanks to the addition of a bearing, that allows, among other things, for vibrations reducing and it is provided with a new intelligent software for the production process analysis and for predictive maintenance.

On 31st August, Mecolpress celebrated its first 50 years of activity by opening its doors to the families of the employees who work at the Flero site every day. In this first half century of activity, there have also been moments of sacrifices and difficulties, but the tenacity and determination of its founders allowed Mecolpress to emerge very quickly in a particular market such as the forging one.

The second generation played an important role in the history of the Rhinoceros, as well, in particular, during the economic crisis of 2008, when the company could make courageous decisions, expanding its business, pushing on the accelerator of innovation and research, trying to renew itself and pushing beyond the borders drawn by parents. Now the company has reached the maturity of an important reality that operates all over the world, where the glorious history of its beginnings coexists with the desire to get involved that has especially characterized with research and innovation the last years.

With the background generated by this mix of values, now also the third generation appears in the management panorama.

Watch the video of our Anniversary Party:

Mecolpress, a new adventure

In 2018 Mecolpress acquired the majority of the shares of ME Group, manufacturing company of electric scooters with an unique design, becoming the reference partner alongside the founders. The entry of Mecolpress formally coincided with the passage of ME Group from Innovative Start Up to Innovative SME. This formal transition was in fact also substantial, thanks to the contribution of Mecolpress from a financial point of view and above all from the point of view of know-how and industrial approach to the organisation of the company. ME is the first scooter in the world with a patented frame made of SMC (Sheet Moulding Compound), a compound of thermosetting resins with excellent performances in terms of strength and resistance in relation to its weight. This electric scooter can be recharged like a mobile phone: it can be fully recharged in 3-6 hours (depending on the battery charger used), connecting the scooter directly to a domestic outlet in the garage or office or extracting the battery.

The ME Start Edition version (sold out) was followed by the range available from the 2019 season: 2.5 kW moped model, 45 km/h top speed (limited by law) and 80 km range and 6 kW model with a speed of 80 km/h. Touch display, USB socket and a range of accessories in continuous evolution complete the equipment of ME.

Company numbers:

Mecolpress has grown over the years both in terms of volume of the industrial area and in terms of numbers. Starting from the employment situation: in 1985 Mecolpress had 29 employees, in 2018 it practically doubled its staff to 55 employees. Turnover and production are also growing: in 1985 the company turnover was just over 2.7 million euros. By 1995, turnover rose to 7.5 million euros and then the last available turnover (2018) exceeded 11.3 million euros.

Over the years production has also gone hand in hand with turnover increase. Today Mecolpress has 559 customers in 59 countries worldwide. All over the world there are 1126 Mecolpress machines, including screw presses (101), mechanical presses (806), hydraulic presses (40) and trimming machines (179). Most of them (763) are located in Europe, but the Flero-based company has also exported in Africa (62), Americas (103) and Asia (198).

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..) in the order of more than 1,000 units, bringing the total production of machinery and spare parts to 2183 pieces.