EXHIBITIONS 2025: MECOLPRESS AT ISH (GERMANY)

ISH 2025

The world’s leading trade exhibition is the flagship and heart of the healthcare and HVAC industry, as well as a unique driver of innovation. ISH focuses on modern bathroom design, sustainable heating and air conditioning technology and smart home systems. Under the motto “Solutions for a sustainable future”, ISH 2025 will be launched with a new, clear and modern event structure.

It will be held from 13 to 17 March 2025 in Frankfurt at Messe Frankfurt.

We look forward to seeing you at our Booth, Stand Hall 9.1 Stand no. C91

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2025: MECOLPRESS AT TIMTOS (TAIWAN)

Timtos 2025

This exhibition will be held at Taipei Nangang Exhibition Center.

The global machine tool industry prepares for TIMTOS 2025, the international trade exhibition with the participation of more than 1,000 exhibitors.

TIMTOS 2025 represents a platform of excellence to discover technological innovations and advanced solutions for manufacturing production.

Mainly the exhibition focuses on three main macro-topics: AI & Robotics, Future Smart Manufacturing and Green Power & Sustainability.

For this reason, from 3 to 8 March 2025 Mecolpress will be at Stand Q0733.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2024: MECOLPRESS AT EUROFORGE conFAIR (MILAN)

EUROFORGE | conFAIR

This exhibition will be held at Allianz MiCo • Milan Convention Center, Italy from 22 to 23 October 2024.

The EUROFORGE conFAIR is the only European fair and conference specifically designed for the forging industry. At EUROFORGE conFAIR we bring together the best suppliers, the most innovative scientists and the leaders of the forging industry in order to discuss the threats and opportunities of the current industrial megatrends and their effects on the forging world.

For this reason, from 22 to 23 October 2024 Mecolpress will be in Milan at EUROFORGE | conFAIR at Hall 3 Stand 130.

Experiences about ferrous and not ferrous hot metal forging presentation

You are invited to participate in the Experiences about ferrous and not ferrous hot metal forging presentation which will be held on Wednesday 23 Oct 2.00-2.30pm at the 2023 Confair Euroforge in Milan .

It will be a useful opportunity to learn about the latest proposals regarding:

- the reduction of the consumption of raw materials.

- the reduction of electricity consumption.

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operational continuity thanks to after-sales assistance.

We will be proud to have your attention and to answer your questions and requests for clarification.

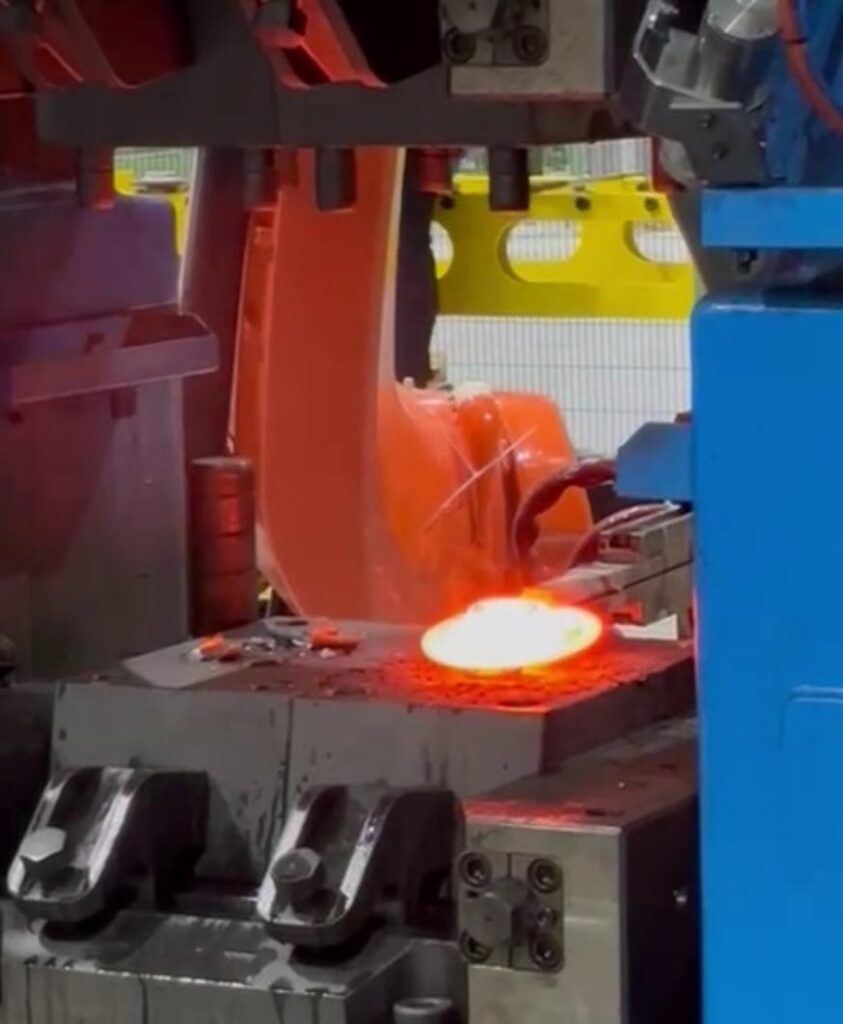

Hot forging in the fashion sector

Hot forging presses are also used in the fashion industry manufacturing.

The worldwide fashion sector is characterized by extremely significant business volumes: around 3 thousand billion euros and it employs 50 million people.

Italy is one of main districts for the fashion industry with historic brands and production chains deeply rooted in the territory.

The sector is affected by global uncertainties linked to inflation, geopolitical tensions, post-Covid recovery but double-digit growth is estimated in the coming years. The increase in business volume is possible thanks to a high dynamism full of creativity and style which canalizes an important flow of news and innovations every season.

The digitalization of sales channels and operational departments and the near-shoring approach have created the need to make the manufacturing process increasingly productive and efficient.

Metals hot forging is a key operation to characterize fashion products and accessories. The logos of the major brands applied on bags, shoes, clothes and belts are made through hot forging and then finished with other downstream processes.

Mecolpress has been the protagonist of this continuous growth process, offering technologically advanced forging solutions with the aim of:

- Increasing production capacity up to 1500 pieces per hour;

- Reducing machine downtimes due to maintenance and tool changes (availability >95%);

- Reducing the consumption of materials, energy and CO2 emissions by 50% (GREEN TECHNOLOGY Industry 5.0);

- Allowing the digital communication between production line and company system and remote diagnostic access (Industry 4.0);

- Flexibility in forging products of different sizes and materials (steel/brass/aluminium);

- Increasing the safety of the production line by reducing human intervention (industry 5.0).

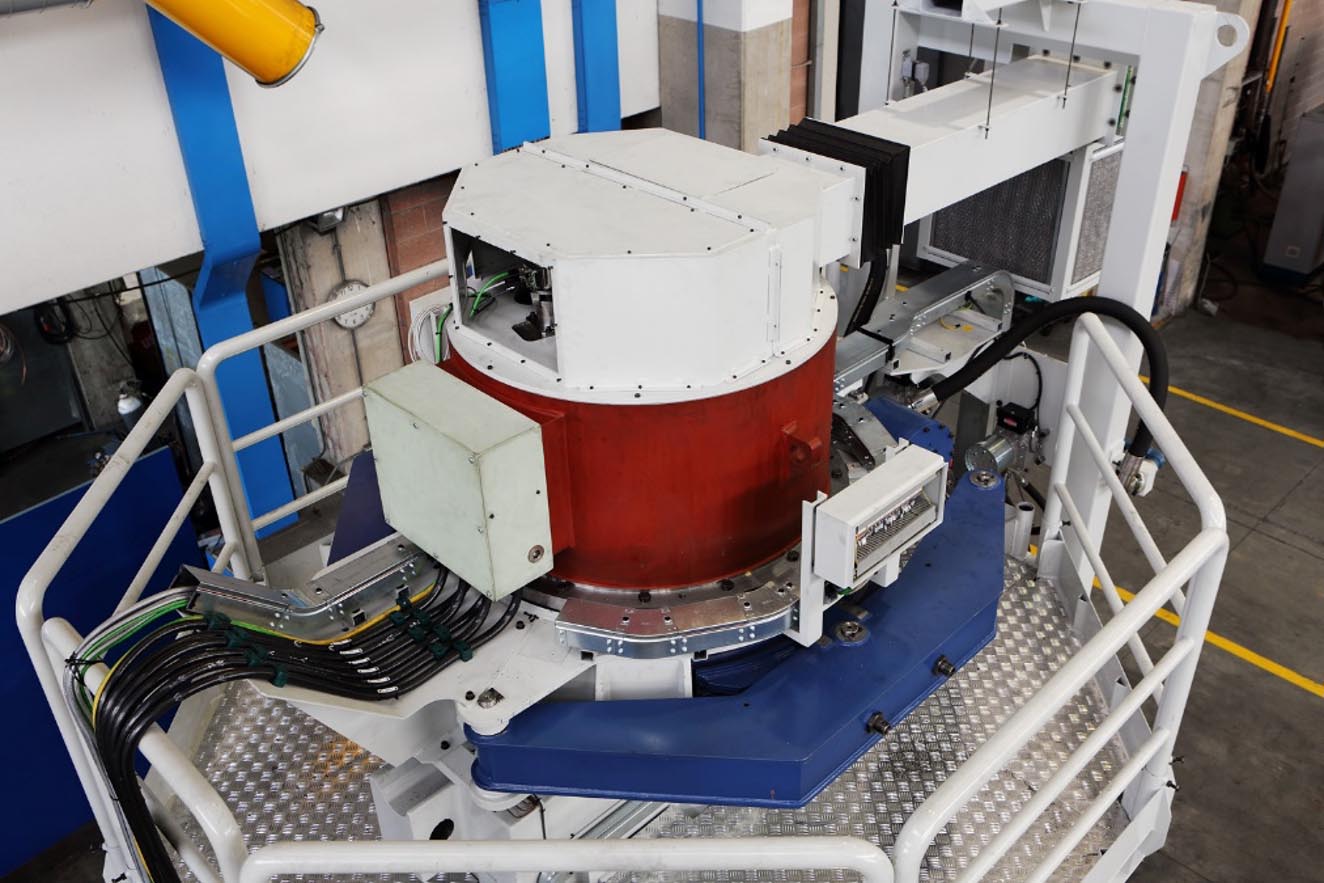

TDS Electrical Torque-Driven Screw presses

TDS Electrical Torque-Driven Screw presses result to be particularly suitable for the hot forging of parts destined to fashion sector.

Here below the 4 strong points that make many customers to prefer these hot forging screw presses:

- Cycle time does not dependent on forging energy => always optimized productivity

- Reduction of friction parts => less maintenance and less energy consumption

- Flexibility in energy settings => production flexibility for product size and type of material (brass, steel, aluminium) and reduction in dies wear

- Energy recovery of braking energy => reduction in energy consumption

Click on the image to enlarge

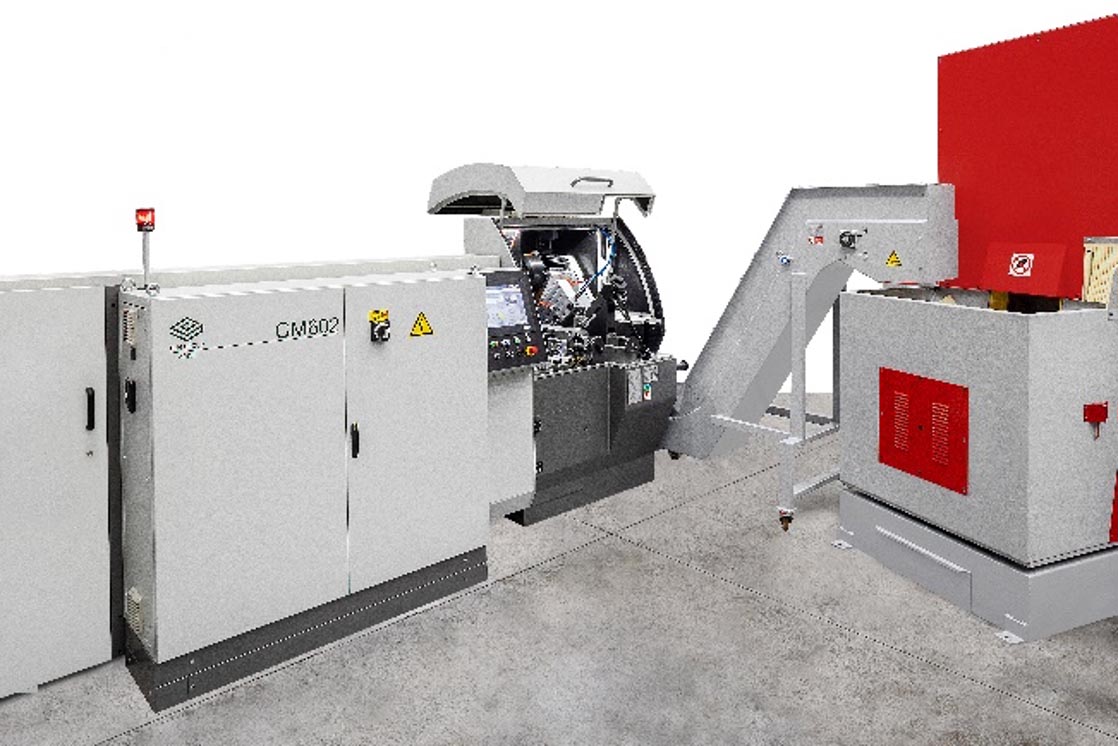

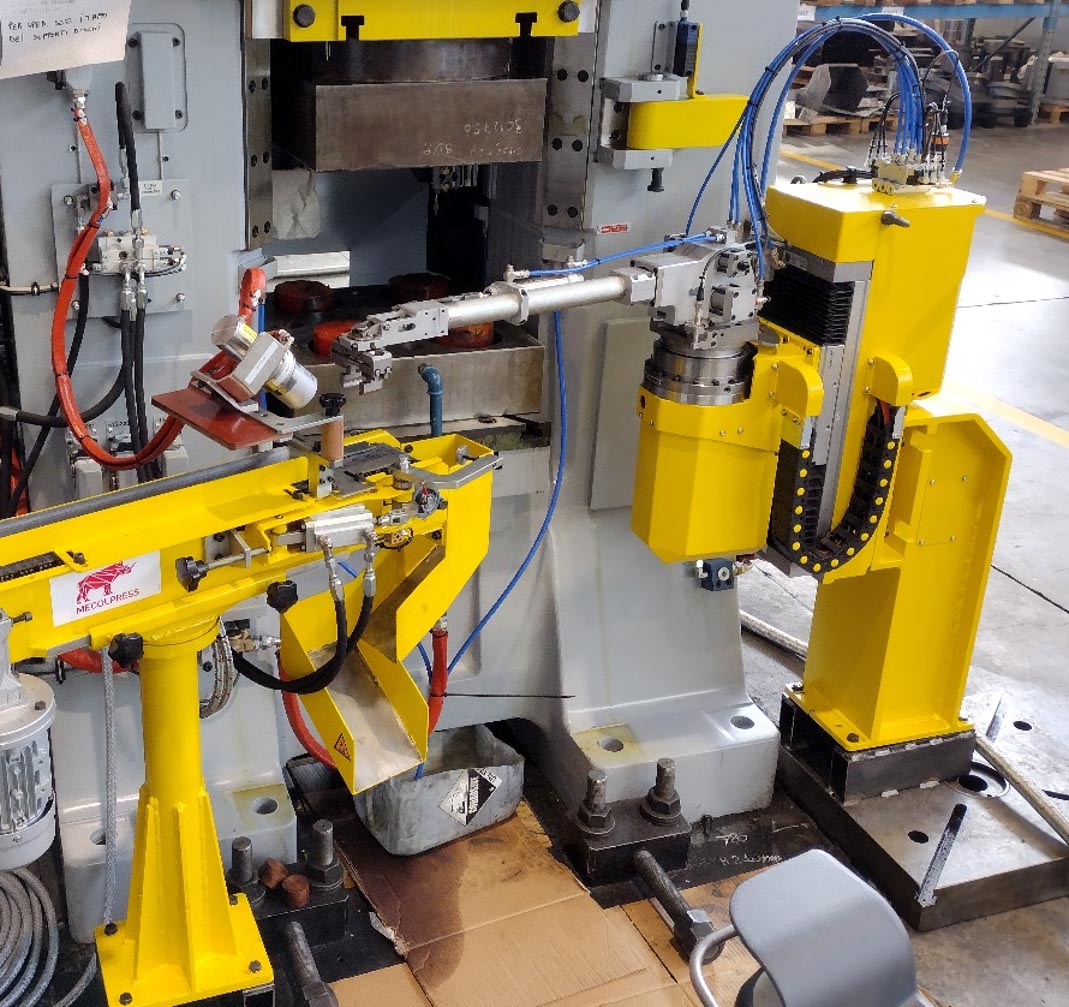

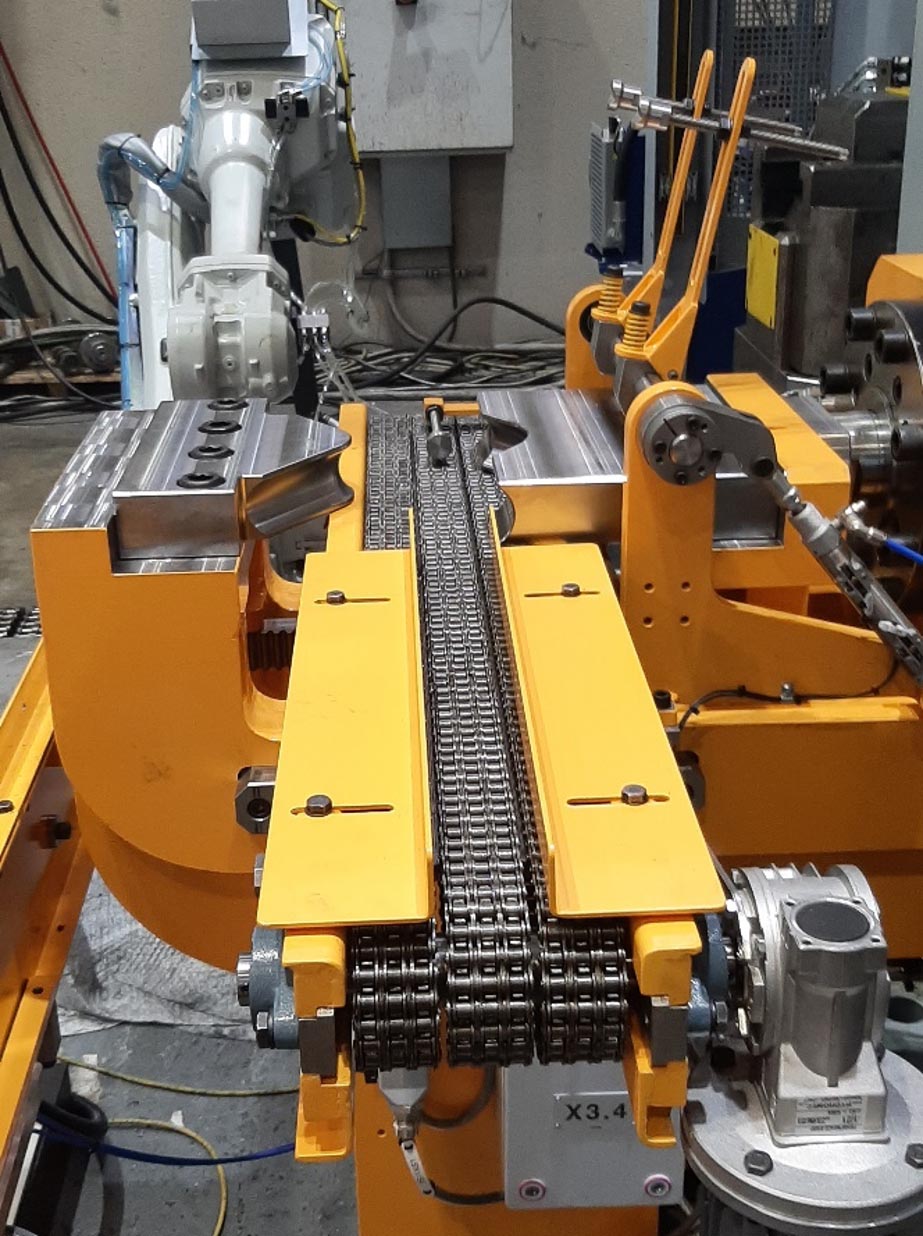

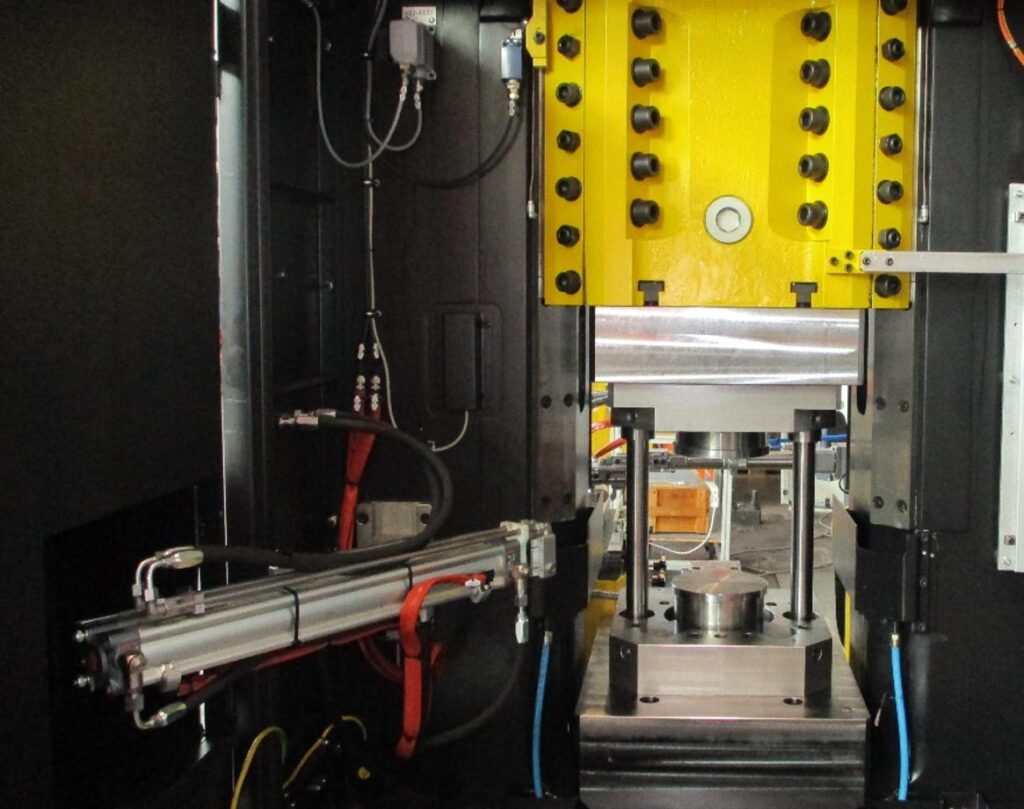

Complete forging lines integration

Even in the fashion sector, the frequent request is to have complete forging lines.

We can supply the line following the customer need, so in addition to the hot forging press, we integrate the cutting, heating, forging and deburring of the forged pieces.

Click on the image to enlarge

The presses for forging of parts destined to fashion sector have to optimize the process phases:

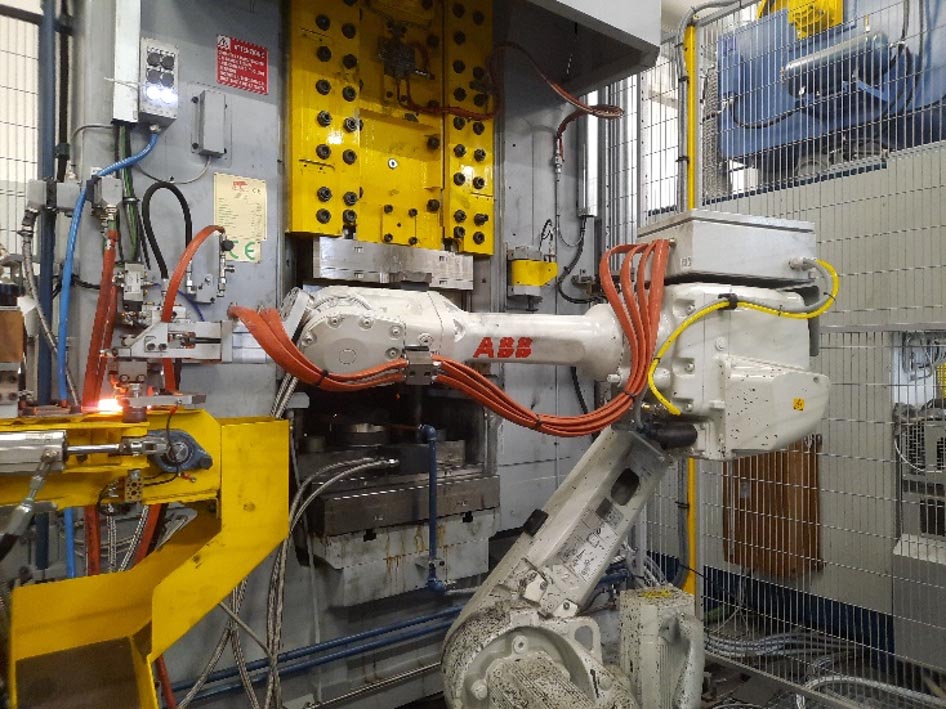

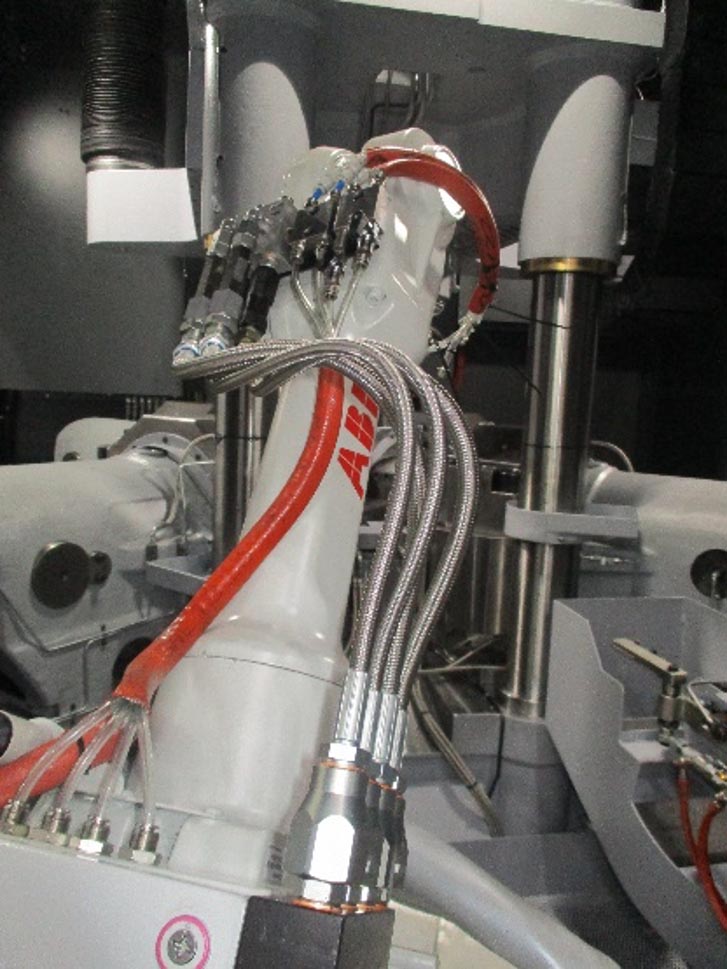

Automation of machine loading and unloading

We underlined the importance of automating the loading and unloading phases of pieces. The presses must include certain solutions to guarantee maximum performance:

- High-speed Cartesian systems for heated material loading.

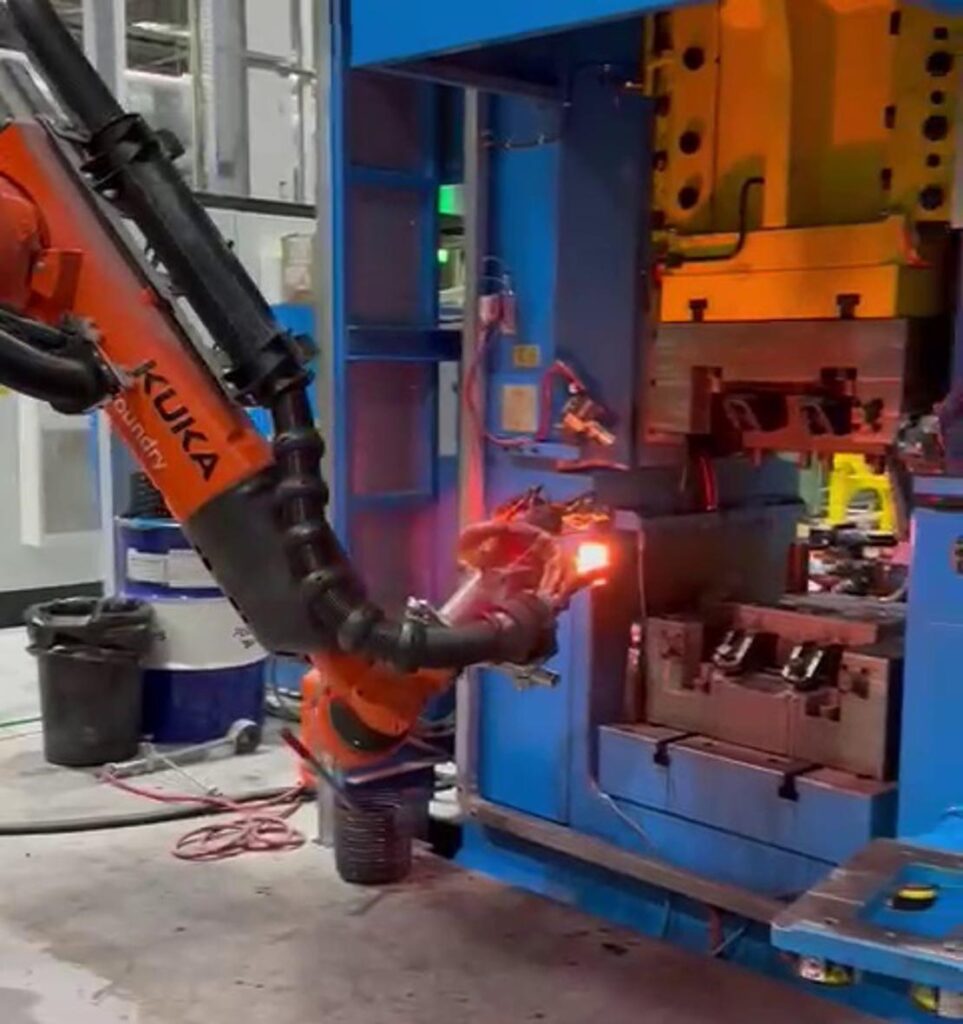

- Flexible anthropomorphic robots for heated material loading.

- Unloading of the forged product via air blow to avoid sliding and contact defects.

- Folding of the material to be forged to have a shape as close as possible to the forged parts and to reduce material consumption.

- Possibility of different shapes of the starting material from the traditional round billet to customized shapes (letters, symbols, …).

Click on the image to enlarge

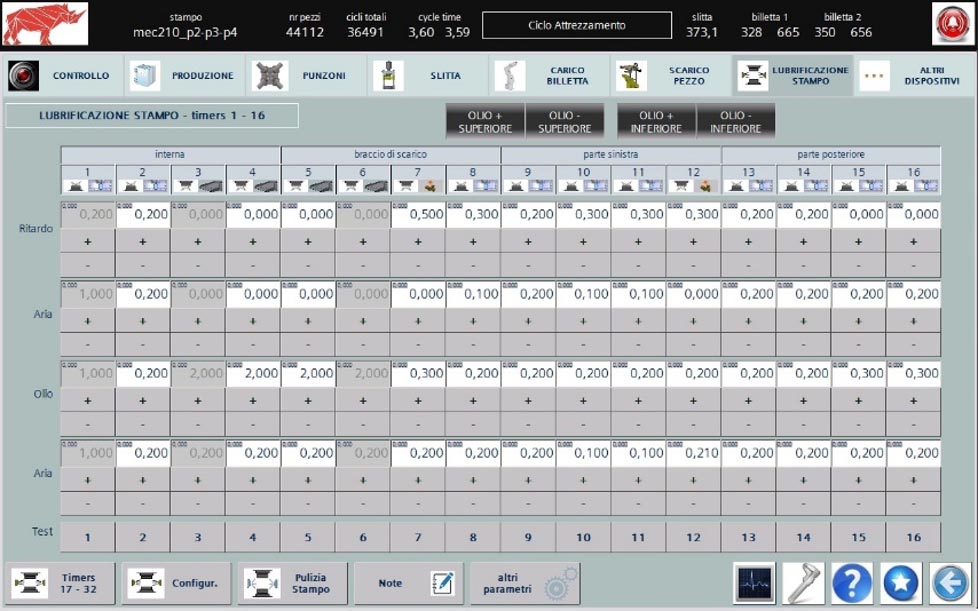

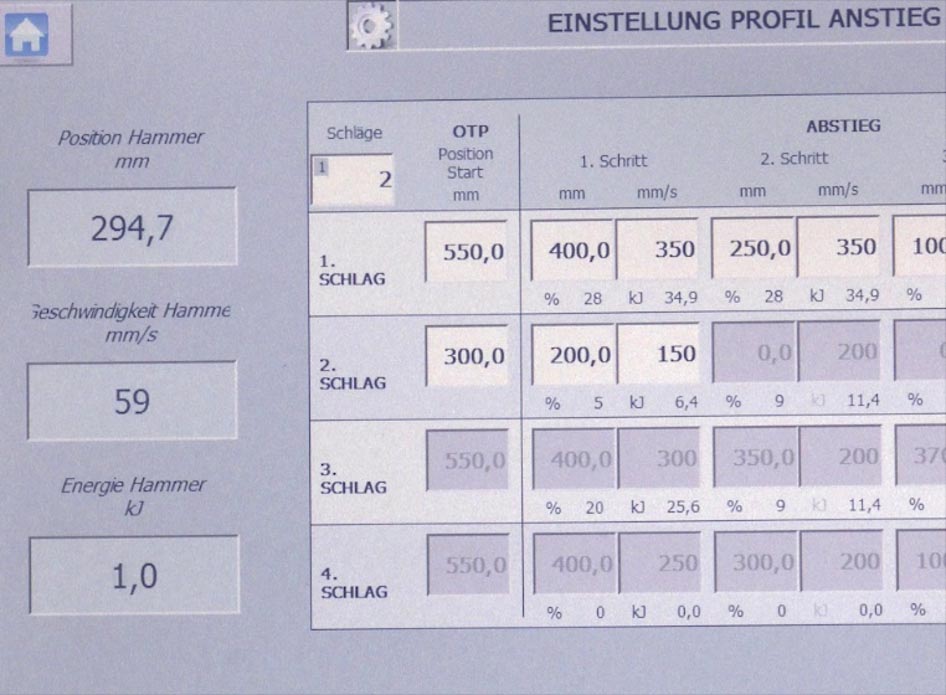

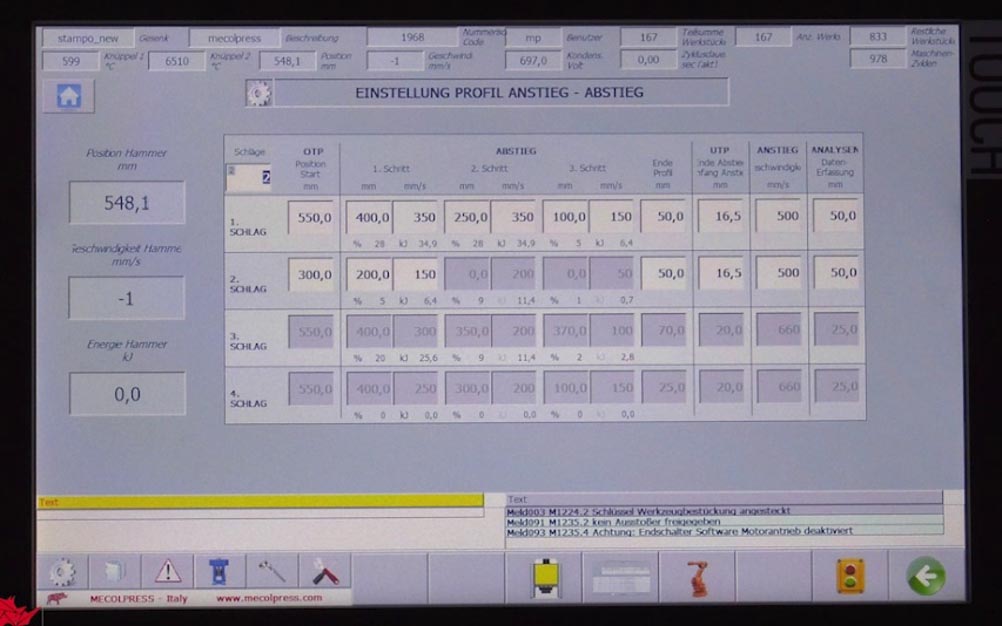

Productive process data control system

An important solution to take into consideration to start a successful hot forging project for parts in the fashion sector is certainly to equip yourself with a control system of the productive process.

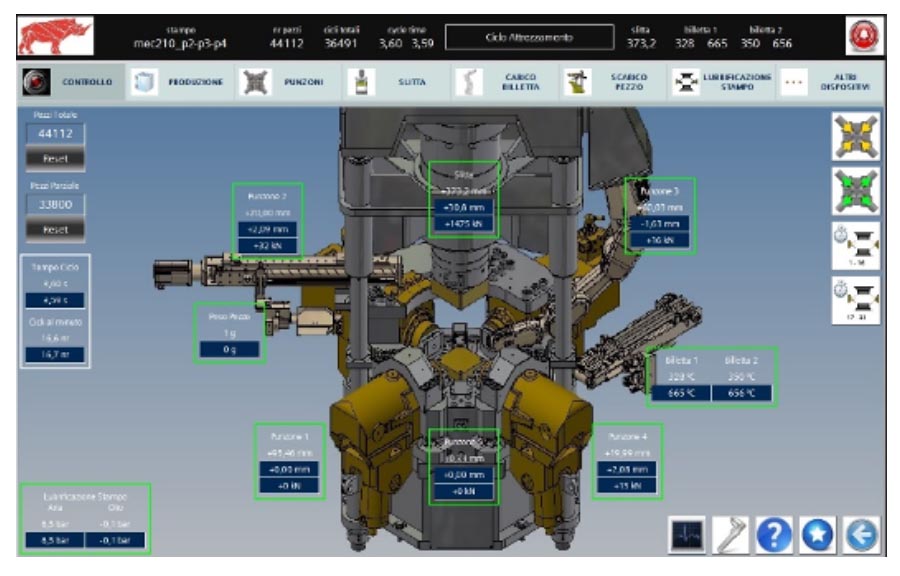

Mecolpress Calipso Software allows to monitor and to adjust the data connected to forging process, and it presents numerous advantages, among which:

- Based on HMI architecture complete with touch screen display

- Functioning parameters of the press and of the auxiliaries that can be inserted from the display.

- For each forging cycle, the main parameters are saved for collection and analysis.

- Integrable with company MES/MRP systems.

- Remote access for diagnostics and problems solving

Click on the image to enlarge

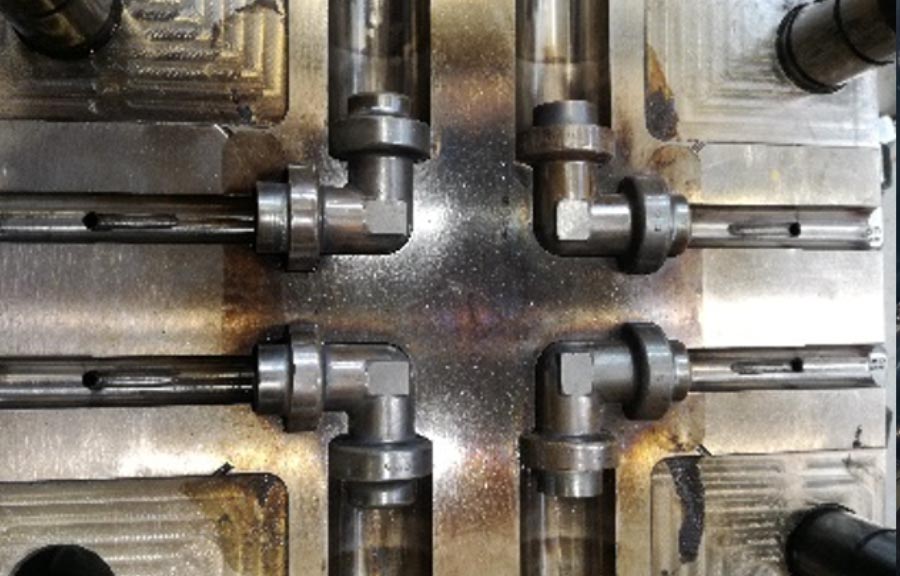

Dies lubrication

The proper dies lubrication makes the difference for a successful hot forging process.

A correct lubrication does not mean a lot of lubrication, but it must be properly dosed, the most suitable lubricants must be chosen based on the metal to be forged and the required piece.

We propose:

- Automatic air-oil lubrication unit managed by the control panel.

- Up to 30 lubrication points.

- Automated lubrication arm synchronized with the forging cycle.

Click on the image to enlarge

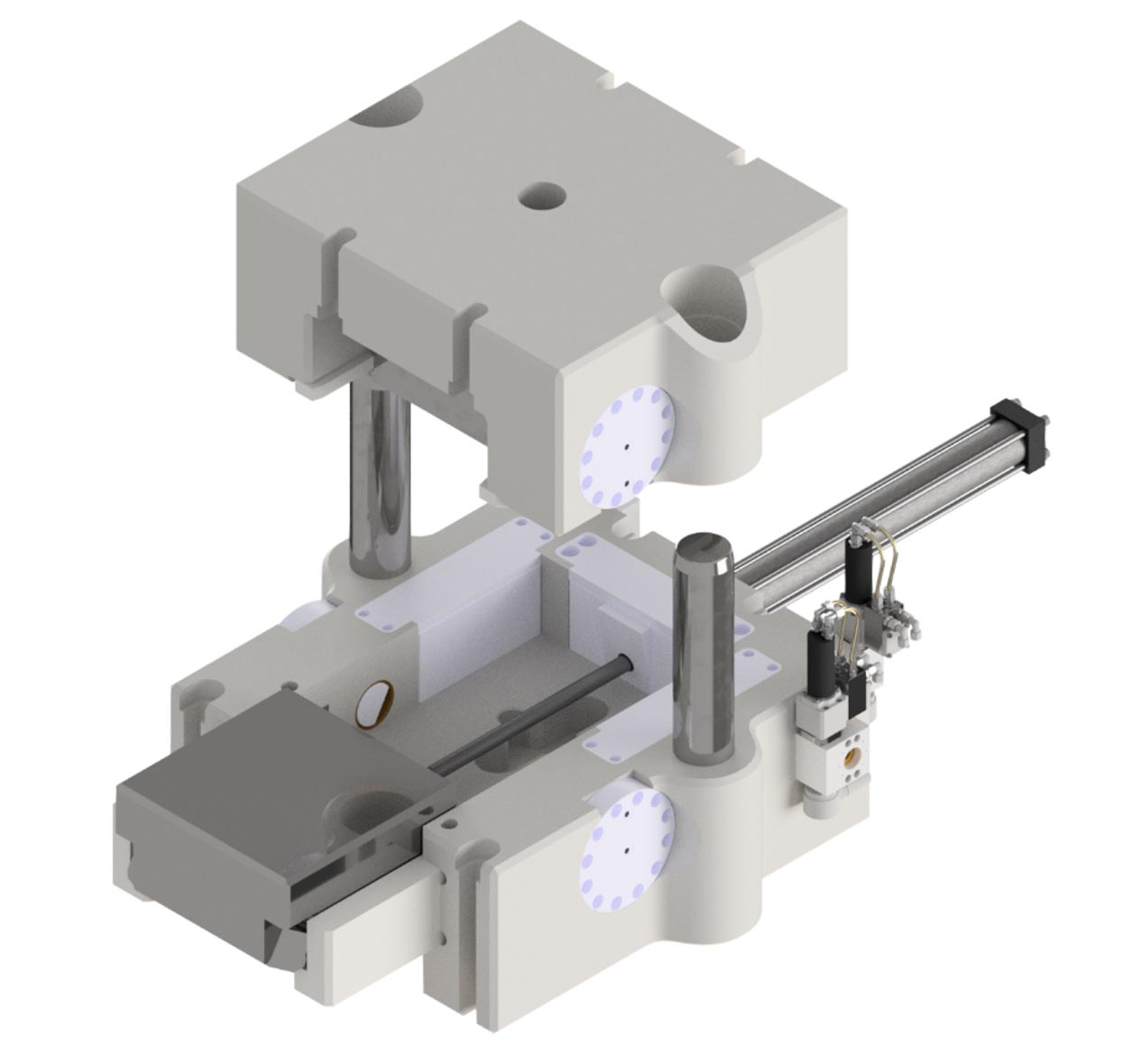

Dies changing system

To allow a quick unlocking, the die holder has been optimized, and the auxiliary arm becomes essential for bringing the dies out of the working area of the press.

Click on the image to enlarge

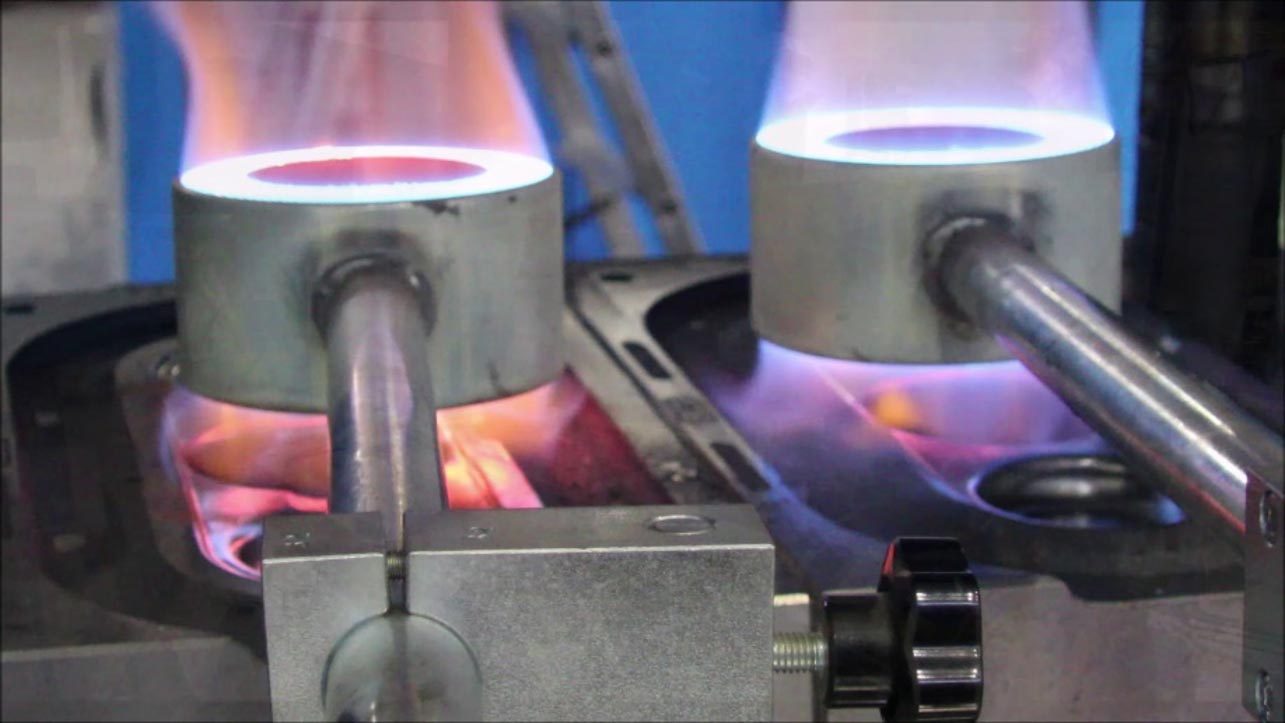

Dies pre-heating

This is an important phase of the hot forging productive process that foresees the use of modern induction technologies avoiding open flames or CO2 emissions.

In the fashion sector, therefore, hot forging presses and related devices are widely used.

It is always important to develop an accurate and successful forging project to maximize profits and reduce waste.

EXHIBITIONS 2024: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2024

Stuttgart Trade Fair Center from 4 to 6 June.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 4 to 6 June 2024 Mecolpress will be in Stuttgart at Castforge Hall 5, Booth 5A37.

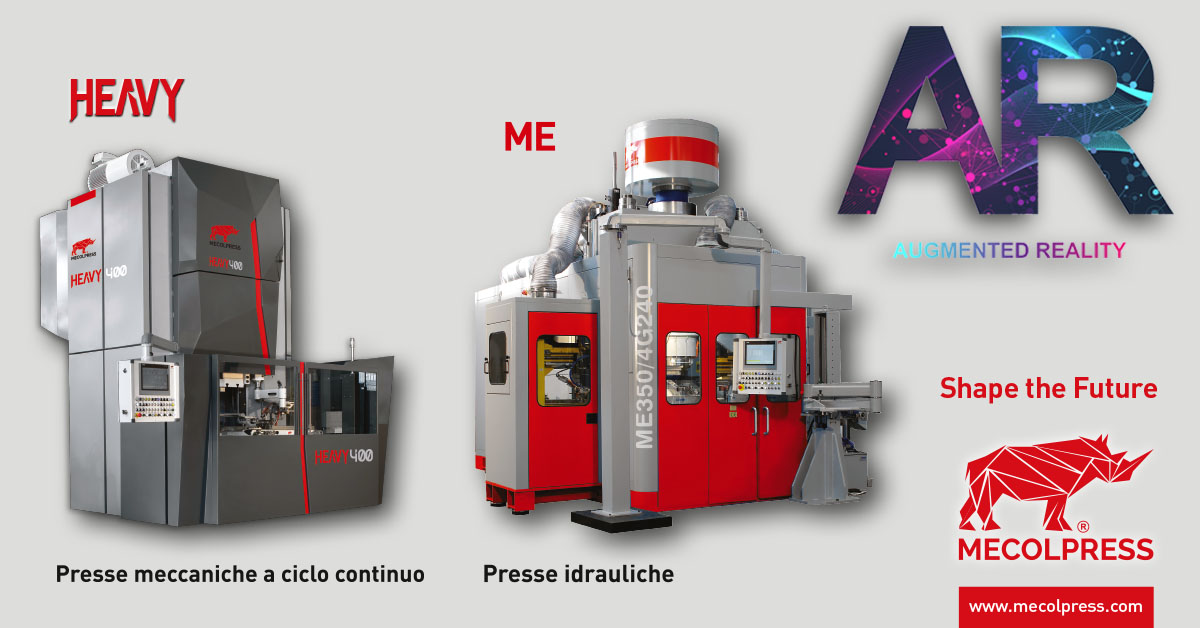

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

If the forging industrial process is stable and steady, it generates profit!

If the forging industrial process is stable and steady, it generates profit!

Today more than ever it is very important that the industrial process, in our case the hot forging one, remains stable and steady during operations time. As a matter of fact, by achieving this goal it is possible to generate profit.

The costs increase in raw materials, energy and specialized personnel is a more and more important and relevant constant for every manufacturing business. The profit of each order or job must always deal with these variables which can hardly be controlled.

The production stability can be controlled: the process must always be repeatable in the performances and must grant steady operative costs.

The metals hot forging is not an exception. Annual productions can reach tens of millions of pieces and each of these must be produced following the expected and planned parameters, the profit expectation must be guaranteed!

How is it possible to manage, monitor and correct tens of parameters, for millions of parts, granting the stability?

It is possible to grant the process stability even when millions of parts are produced and the process parameters are numerous, in this way:

01

=> monitoring the variability factors that influence each process to understand if they are under control or not by means of the statistical control.

02

=> Obtaining highest rigidities, forging force, and positioning precision.

03

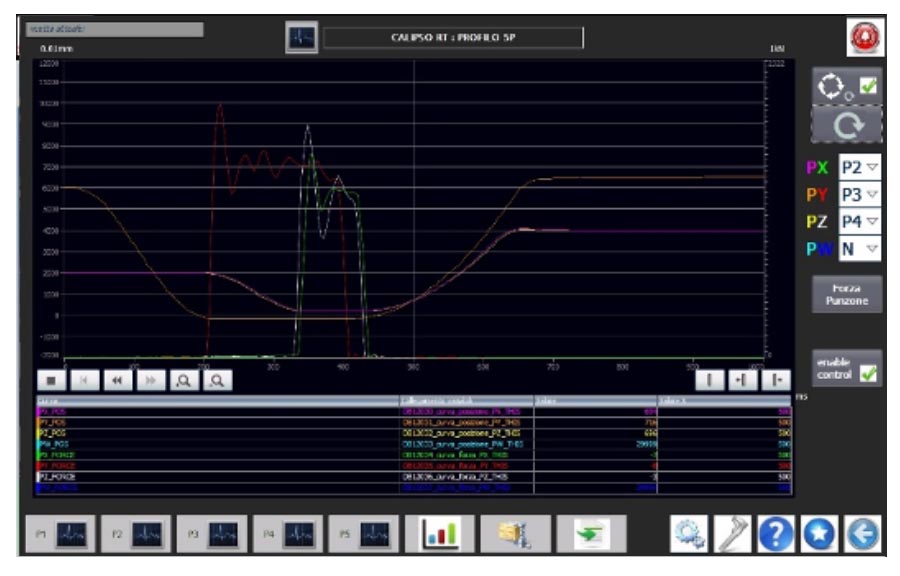

=> Real time check of the behaviour of the main process parameters.

04

=> Modification of the main forging values without interrupting the production.

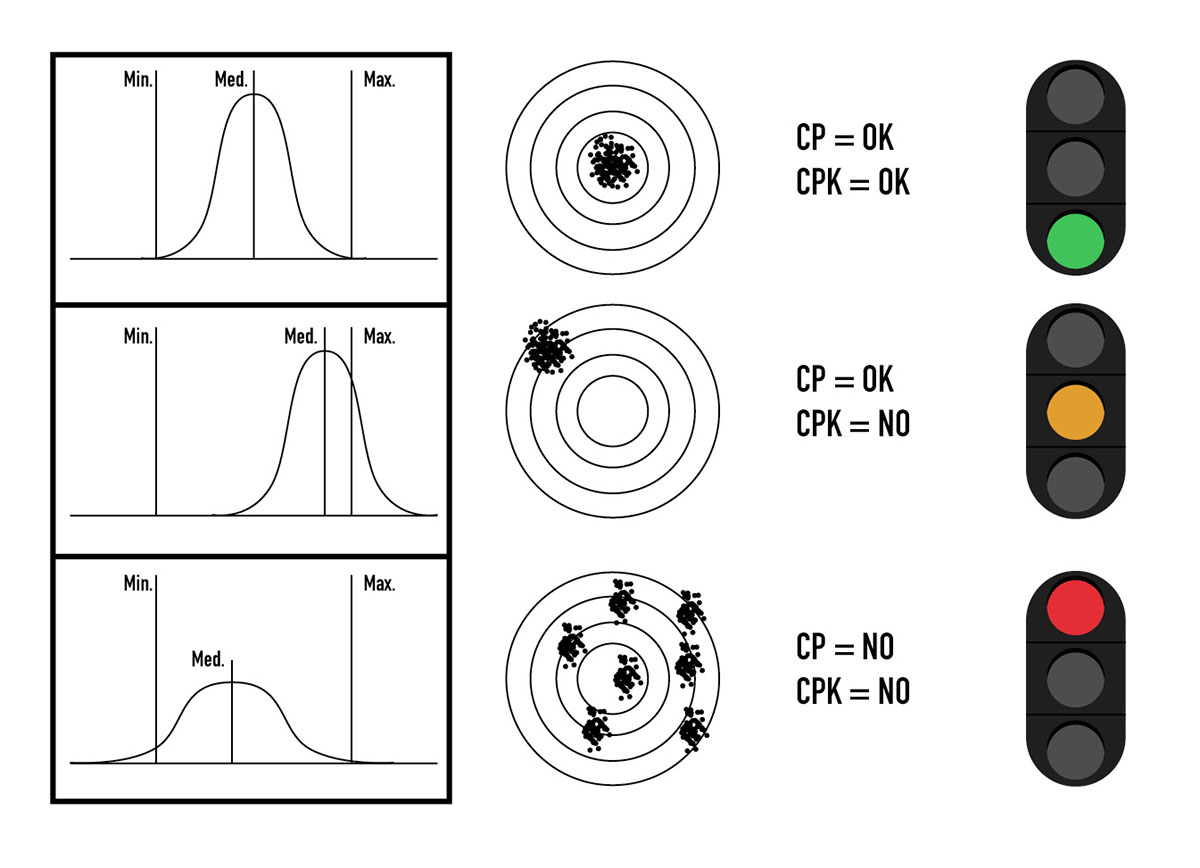

Statistics teaches that Cp and Cpk parameters are fundamental for controlling the progress of the forging process, for each variable in fact they are the key to understand its stability.

The example of the shooting with darts game allows you to quickly understand the concept:

a good Cp indicates that we are very repeatable in our shots, but it does not mean that we are hitting the target.

Only by obtaining a good Cpk, too, as a matter of fact, the optimal result is guaranteed!

=> Cp e Cpk must be much higher than one.

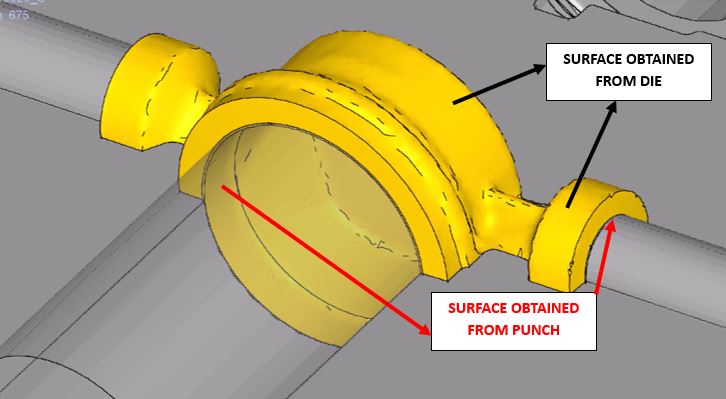

Let’s move on to a practical forging example:

-

Forging a batch of 25,000 water meters.

-

or forging a batch of 50,000 gas control valves

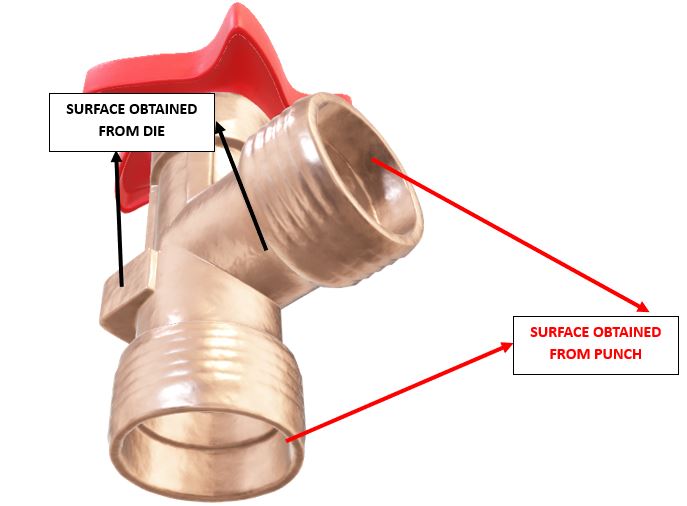

The dimensions of the forged parts are determined:

- by the surfaces of the part shape created in the die.

Cp depends on the presses rigidity performance and on the die design.

Cpk depends on the correct evaluation of the material shrinkage, which is related to the forging temperatures, to the part geometry and raw material chemical composition.

- by the punches involved in the material deformation.

Cp is obtained from punches rigidity and thrust force.

Cpk is obtained from the possibility to adjust the punch arrival position.

During the forging tests carried out with our customers from all over the world, the dimensional statistical analyses carried out on the produced samples (batches of thousands of pieces) have demonstrated that Cp and Cpk parameters were always abundantly and stably higher than one.

The complex geometries or the parts dimensions are not a problem.

How could we maintain the forging industrial process stable on our ME Hydraulic Presses?

- Mecolpress presses are equipped with Calipso software for operative parameters setting and their continuous control. Calipso, software entirely developed by Mecolpress, allows you to control the main process parameters in real time (forging forces, position, speed, …). Even before measuring the pieces, it is possible to understand if the forging process is stable and guarantees constant performance.

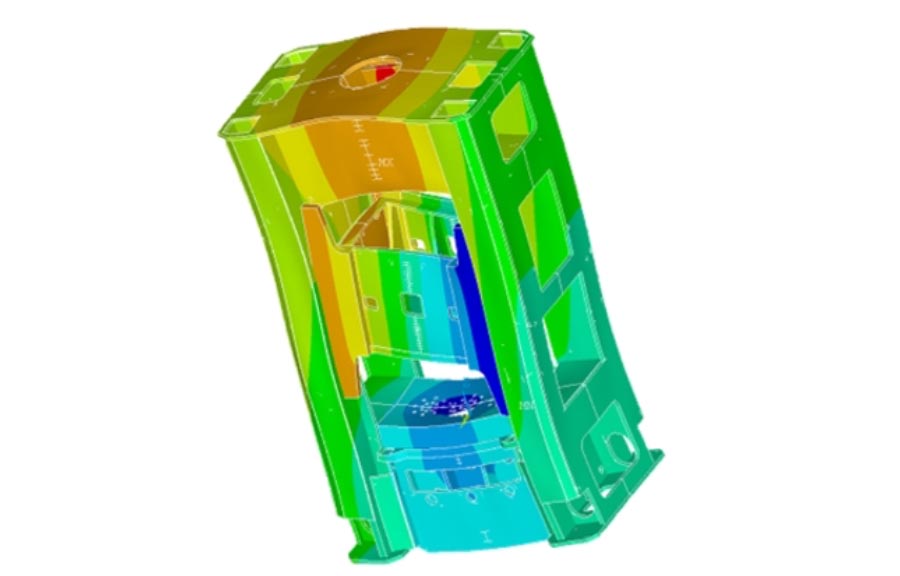

- Our presses are designed with advanced calculation systems (FEM) which allow to predict the rigidity of the components with the utmost precision, minimizing their deformations, even if subjected to high loads.

=> Cp under control

- We have designed our hot forging presses in order to have the highest possible dies closing force and maximum punch thrust force.

=> Cp under control

- The stroke adjustment of the individual punches occurs in real time, thus allowing the related dimensions to be modified during production.

=> Cp under control

- The long experience in dies design and the collaboration with the best specialized companies in the sector have allowed us to create the dies with extreme accuracy, in order to guarantee stable production of the pieces.

=> Cp under control

MCE EXHIBITION IN MILAN + OPEN DAYS IN MECOLPRESS

MCE EXHIBITION IN MILAN

For over 60 years MCE – Mostra Convegno Expocomfort (Milan) has been a key event for innovative air conditioning and energy efficiency technologies.

Companies that design, build and install systems for the heating and air conditioning of industrial, civil and commercial environments meet to exchange experiences, find new Customers and strengthen collaborative relationships.

The value of the global HVAC market is estimated at more than 200 billion dollars and is expected to reach close to 300 billion in 2027. The increase in “smart” applications in the construction of buildings, the demand for increasingly efficient systems to deal with growth in energy costs, the greater demand for cooling systems in areas where they were not previously necessary, drive this growth in value.

INNOVATION, SUSTAINABILITY and ENERGY EFFICIENCY will be the cornerstones of this edition which will combine digital events and in-person meetings. The former facilitate the reduction of distances and communication ease, the latter allow us to consolidate relationships and better understand needs.

Looking forward to meeting you at MCE – Mostra Convegno Expocomfort

12-15 March 2024

at Milan Exhibition at booth T22 Hall 4 Milan Exhibition, Rho (MI)

MECOLPRESS OPEN HOUSE

Concurrently with the presence at Milan Exhibition, Mecolpress has decided to inaugurate some Open House days and give you the opportunity to see some of our machines directly in our factory.

All our last and innovative mechanical presses (HEAVY\SEO), hydraulic presses (ME) and screw presses (FDS\TDS) will be available to be seen in assembly/testing phase.

Looking forward to meeting you in Mecolpress on the occasion of our Open Days

11-15 March 2024

For further information and to get a free entry ticket to MCE Exhibition, contact us on +39 030 2560110 or write to us at sales@mecolpress.com

Exhibitions 2024: Mecolpress at AHR (U.S.A.)

AHR 2024

AHR EXPO – CHICAGO

The largest event in the HVACR industry returns to Chicago.

Three days dedicated to the latest energy saving solutions and sustainable technology in the field of heating, ventilation and air conditioning systems.

It will be held from 22 to 24 January 2024, in Chicago at McCormick Place .

We look forward to seeing you at our Booth: South Building – Stand S10262

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Reduced energy consumptions with the new hydraulic ME presses

The new Mecolpress ME hydraulic presses grant reduced energy consumptions.

How did we get to achieve this goal?

Mecolpress has been working with its customers for more than 50 years providing the best forging technologies that allow to maximize the quality of the products and the related productivity.

The forging process improvement needs do not always seem to proceed in the same direction:

- the energy consumption reduction requires the reduction of the installed power;

- the high productivity and the raw material reduction require increasing installed powers.

Our customers and partners are dealing with this conflict and are wondering how to come out as winners.

“Which is the most abundant existing source of energy? the least polluting, least expensive, most immediately available one: that is, energy saving …”

Piero Angela

What does Mecolpress propose to grant in the same page reduced energy consumptions and high productivity?

Mecolpress is not afraid of challenges, indeed it knows that these represent an opportunity to grow and improve.

Thanks to the continuous and accurate control system, Mecolpress presses determine and memorize the process parameters at every fraction of a second, i.e. the minimum force and speed requirements to obtain a certain product with the best characteristics. Under these values it is not possible to obtain an acceptable product.

Our long experience has allowed us to evaluate numerous forging cases, from small connectors of ½” up to large valves/water meters of more than 2”, in standard and lead-free brass grades.

To reduce power when it is not needed and to maximize it when it is needed! This is the secret.

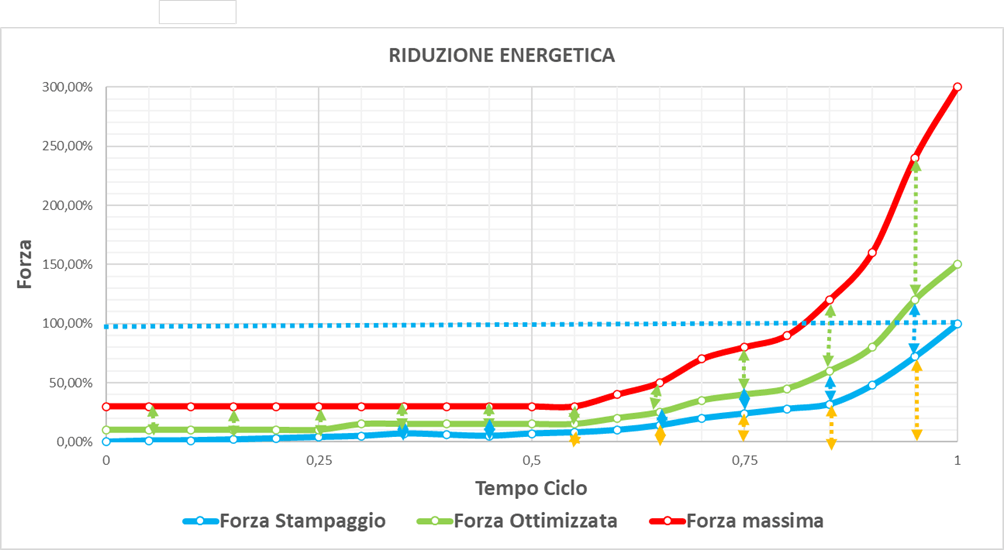

The forging process control system

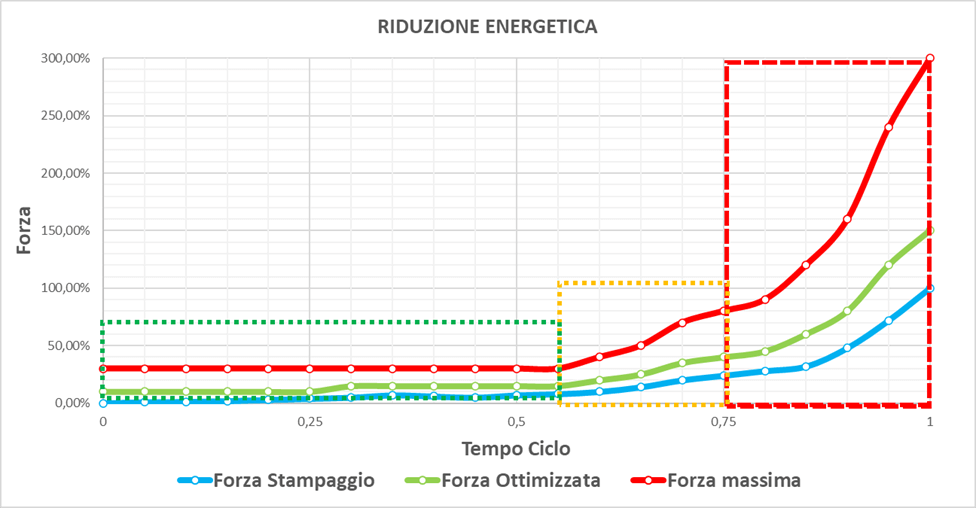

The press control system learns (ADAPTIVE CYCLE) the trend of the forging cycle and regulates the pressure and the flow of the oil (REGENERATIVE CYCLE) in order to get as close as possible to the minimum forging force. A reasonable safety margin is maintained in order to compensate for eventual external parameters variation (billet temperature, material quality, dimensional tolerances, …).

During the forging cycle Mecolpress press will have three phases: power reduction, transition, maximum power.

We monitored the flash-free forging process of the body of a 1 1/4″ ball valve with a productivity of 12 pieces per minute, therefore 720 pieces per hour.

Thanks to the ADAPTIVE-REGENERATIVE cycle the energy consumption is reduced by 50%, reaching an average consumption of 45kWh.

But let’s not forget the other advantages acquired:

- production capacity more than doubled compared to the traditional cycle,

- high repeatability of the piece quality (cp>2),

- constant compliance (cpk>1.33) with very tight dimensional tolerances (± 0.1),

- minimized material consumption thanks to over 6% flash-free forging,

- improved workability thanks to a more uniform internal conformation,

- increased product quality thanks to the elimination of internal defects.

EMO 2023

EMO 2023

EMO is the world machine tools trade fair which is hosted by Italy and Germany and which this year will be held in Hannover from 18 to 23 September 2023.

Undisputed leader in the panorama of sector trade shows, EMO best represents the articulated world of metalworking, showing the best of vision and innovation.

Tooling machines, robots, enabling technologies and automations, solutions for the networked and digital factory, additive manufacturing and green innovations will be among the key players of EMO 2023.

Mecolpress as global leader in hot forging technology cannot miss this important event.

It will be a very important opportunity to meet our Customers and the new potential ones.

Mecolpress sales team and technical staff will be glad to welcome you in person to evaluate your requests and offer you our competitive solutions.

Mecolpress presents the latest innovations related to forging technologies:

- SEO and HEAVY eccentric mechanical presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- Hydraulic presses of ME series: flash-free forging with outstanding reduced energy consumptions.

- Direct drive screw presses: to produce parts of complex geometry.

Mecolpress innovations

The fair will be a useful opportunity to get to know the latest proposals regarding:

- reduction of raw materials consumption;

- reduction of electricity consumption;

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operative continuity thanks to after-sales service.

Augmented Reality, the press just a click away

On our stand you will be able to view 2 presses in Augmented Reality: ME and the Heavy presses.

This technology allows you to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the view of the surrounding environment with additional contributions in digital format.

We are waiting for you: Hall 13 Booth D060

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to obtain the free admission ticket.

You can request it by simply filling out this form: