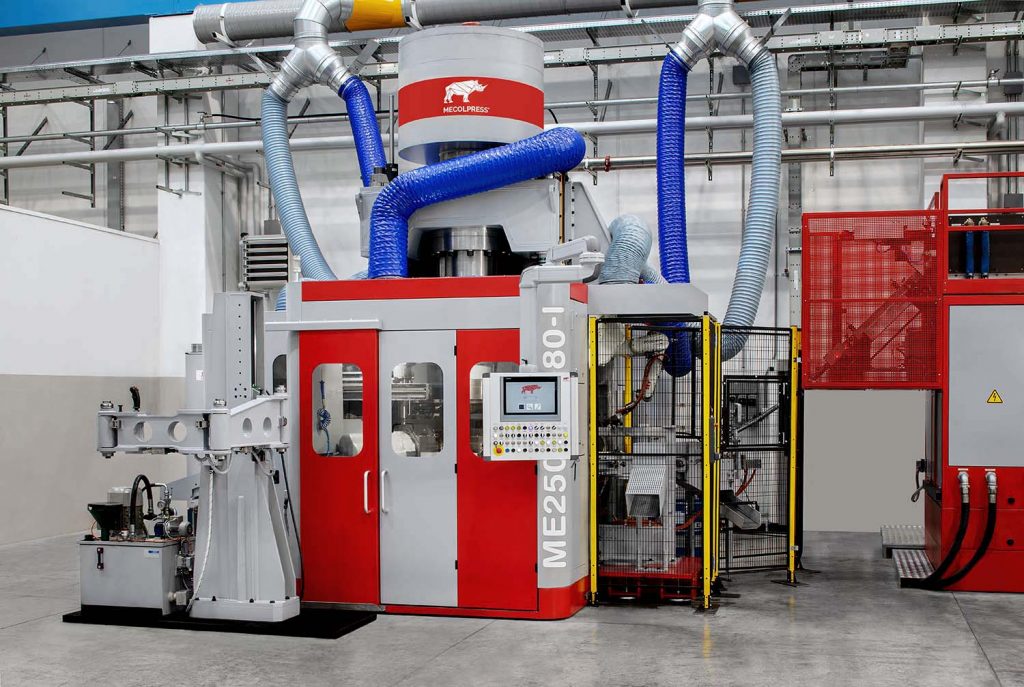

ME 350 NEXT GENERATION PRESS

ME 350 Next Generation Press: still the most powerful press, now it also minimizes the energy consumption.

ME350 press is the powerful of Mecolpress hydraulic presses: the latest version we have developed is able to grant a significant reduction in energy consumption.

Our goal is to make our customers more competitive in a very challenging market. The increase in the costs of raw materials and energy is not yet stabilized and a substantial reduction is not yet in sight. Our customers have to manage and deal with variables such as:

- product differentiation,

- the need to adapt to high volume production batches,

- managing frequent product changes,

- the difficulty of finding a stable workforce,

- the need to produce just in time,

- the increasingly high quality required of the forged product.

Mecolpress technological innovation starts from the challenges the market imposes on producers with the aim of overcoming them.

The new ME350 Next Generation press incorporates all the latest innovations:

01

Maximum dies closing force and maximum one of the independent extruder punches => flash-free forging and reduced thicknesses => reduction in raw material consumption (up to 40% compared to traditional forging).

02

Regenerative hydraulic circuit and adaptive power control to harmonize the energy consumption with the effective forging demand => reduction of electricity consumption (up to 50% compared to the presses of previous generation).

03

Anthropomorphic loading robot and quick dies changing system => increased flexibility by changing a product with another, reducing the necessary machine downtime.

04

Possibility of forging more parts each cycle in the shortest time, reaching the production of 5,000 pieces per hour => high-volume production batches are completed in a short time.

05

The production process is fully automated and connected to existing MES\ERP systems (Industry 4.0) => better staff management who can easily manage multiple presses simultaneously without stress.

06

CALIPSO Software checks the trend of the forging parameters (forces, displacements, sequences, ..) by comparing them with the references => any possible criticality on the quality of the product is overlined in real time and the part is separated from the correct ones.

All these innovations are added to Mecolpress long-lasting experience in the forging field, gained in the province of Brescia, a key area in the global panorama of the production of brass components. Mecolpress offers to the customers a vast availability of spare parts to minimize the relative delivery times and a team of specialized technicians to carry out assistance interventions all over the world.

EXHIBITIONS 2023: MECOLPRESS AT FORGE FAIR (OHIO)

Forge Fair 2023

The United States of America is the country with the highest Gross Domestic Product and has always represented the reference point for the world economy. The tradition of the US manufacturing industry is long-standing and its importance is always growing in every sector. PRODUCTLY MADE IN THE USA!!

Mecolpress with its 50 years of experience in hot metal forging is proud to make its know-how available to make American customers and partners more competitive. Mecolpress has started this process since the 70s and hasn’t stopped yet.

We are proud to announce our presence at Forge Fair 2023 which will be held in Cleveland (Ohio) from May 23rd to 25th. Forge Fair, organized by the Forging Industry Association, is the largest and most important event in North America exclusively dedicated to metal stamping and forging. It will be a pleasant opportunity to discuss and connect the main industrial players in the sector with the aim of increasing their knowledge of production processes and improving them as much as possible.

Mecolpress presents the latest innovations related to forging technologies:

- SEO and HEAVY eccentric mechanical presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: forging without burr with significantly reduced energy consumption.

- Direct drive screw presses: to produce parts with complex geometry.

Smart Brass Forging Presentation

You are invited to participate in the SMART BRASS FORGING presentation which will be held on Tuesday 23 May 3.20-3.45 pm (ET), a useful opportunity to learn about the latest proposals regarding:

- the reduction of the consumption of raw materials.

- the reduction of electricity consumption.

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operational continuity thanks to after-sales assistance.

We will be proud to have your attention and to answer your questions and requests for clarification.

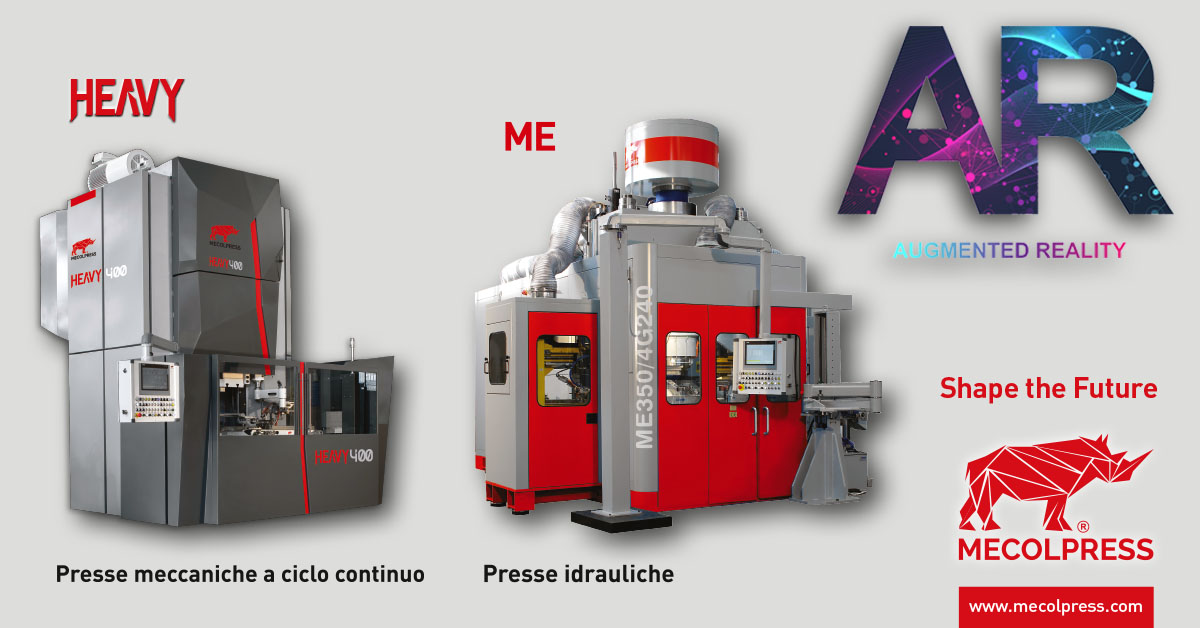

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Mecolpress together with its USA partner Forging Equipment Solution, awaits you at Stand 329 – Exhibit Halls A-B

A CUSTOMIZED TECHNOLOGY FOR THE PRESSES

Courtesy of Publitec

Magazine Deformazione N.281 FEBRURY 2023

of Aldo Biasotto

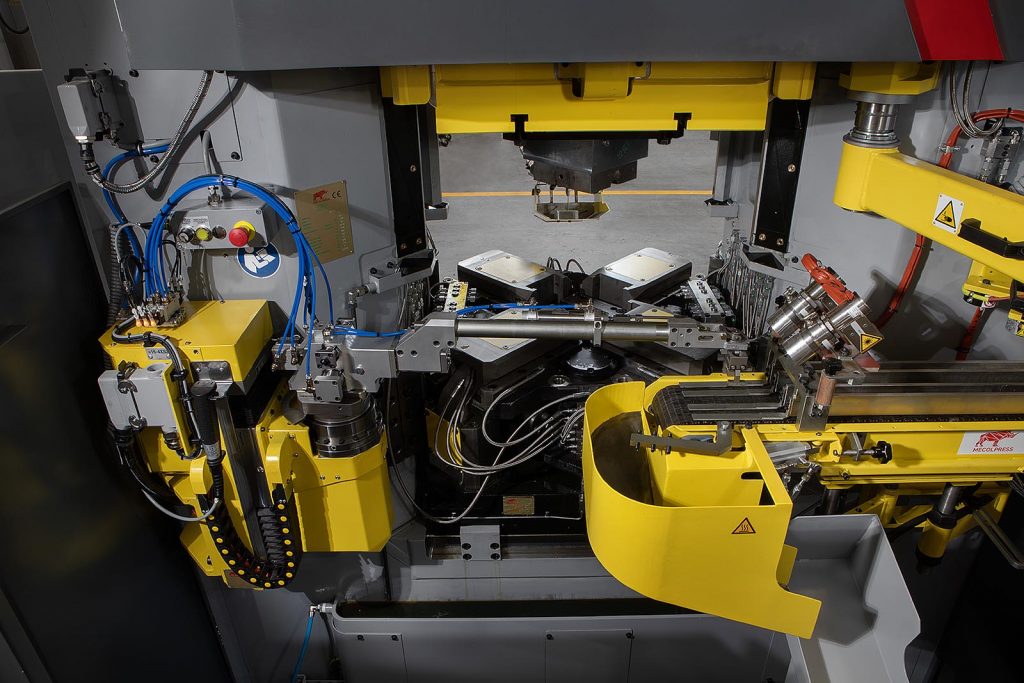

Mecolpress has chosen to make use of the customized solution proposed by Siemens, SIMAHYD, to ensure high reliability and better control of the forging process. This solution is combined with Simatic controllers, allowing both control of the hydraulic valves and management of the variable speed pumps.

Mecolpress is a company specialized in the production of machines and systems for hot forging.

Its story begins in 1969 in the Brescia area: here, for over fifty years, the company has been innovating and developing ever new solution to remain competitive on the worldwide market. The heart of Mecolpress beats in Flero (Brescia) where the technologies are designed and manufactured in an industrial area of 30,000 square metres, 10,000 of which are covered by buildings. With a staff of around 60 people, to date Mecolpress has distributed around 2,000 presses to customers in 60 countries all over the world. The context in which the company operates is broad and differentiated . At the beginning it was only focused in the brass hot forging applications, in particular in the production of fittings, valves and fashion products.

Later on, it was expanded to the world of steel, aluminium and special alloys applications, both hot and cold, thus embracing further sectors: automotive, industrial, medical, sports up to watches. To remain competitive on a global scale and bring an innovative contribution to the metal forging market, where the scenarios for the future are increasingly challenging, Mecolpress needed to rely on a top-level partner for technological components.

Thus was born the collaboration with Siemens, in particular regarding the electrical and electronic supply to the company. The goals: to ensure a high reliability in the presses functioning and better control of the forging process.

The way to reach these goals: SIMAHYD. “Siemens offers new solutions regarding power and process control, on a large scale and for different applications. To be successful, you need to be innovative in making your customer competitive: the synergy between Mecolpress and Siemens allows to reach this goal” says Maurizio Razio, Electrical Engineering Manager of Mecolpress.

The advantages of an open and customized package

To pursue this goal, Mecolpress therefore made use of the customized SIMAHYD solution. It is about a custom-built application package, specifically designed for Simatic S7-1500 controllers, which allows the control of hydraulic axes thanks to software modules that extend the functionalities of the original technological objects in Siemens controllers. In this way, both a control of the hydraulic valves and a management of the variable speed pumps are obtained.

The high level of flexibility of applications in the hydraulic sector facilitates a quick and simple control implementation: this was the case of Mecolpress technologies. By applying this solution to the presses, thanks to this package it was possible to ensure the control of the proportional valves on which the seven hydraulic cylinders depend. “The advantages of SIMAHYD open package are many: it allows to make the modifications necessary for integration into the hydraulic circuits of the machines, preserving the existing control program and, to facilitate the axes set-up, it also includes the display part, also It can be integrated into the existing operator interface.

Furthermore, this application is characterized by controller type “fail-safe”, which facilitates an integrated management of the entire machine safety”, explains Sergio Mazzon, OEM Business Developer of Siemens Digital Industries in Italy. Thanks to this customized solution, it was therefore possible to quickly manage the hydraulic power axes, such as those present on the ME Next Generation series presses, reaching extremely high precision and repeatability.

A technologies portfolio for each customer

Today Mecolpress can offer a complete portfolio of technologies according to the application needs of the Customers: eccentric mechanical or screw presses, hydraulic presses, auxiliary presses. The benefits are many and related to both the presses and the complete forging lines: high production capacity with reduced cycle times; high efficiency thanks to the minimization of energy, raw and semi-finished material consumptions; product quality control by monitoring process parameters; complete automation of the production cycle thanks to the reduced intervention of the operator; technologies allowing quick tooling change between one product and another one, in order to manage small production batches too; compatibility with industry 4.0 and arrangement for predictive analysis systems for maintenance and processes; remote or in person assistance service and spare parts warehouse suitable for a prompt response in case of need.

Thanks to the experience gained and the particular attention to innovation, today Mecolpress is able to face the growing challenges of the market head-on. “Thanks to a reliable partner like Siemens, our technologies are perceived as improving and taken into consideration for investments in new industrial assets. The prospects for growth in turnover and market share are solid and demonstrated by the numbers of the last two years and by the orders portfolio acquired” says Danilo Fagnani, Sales Manager of Mecolpress.

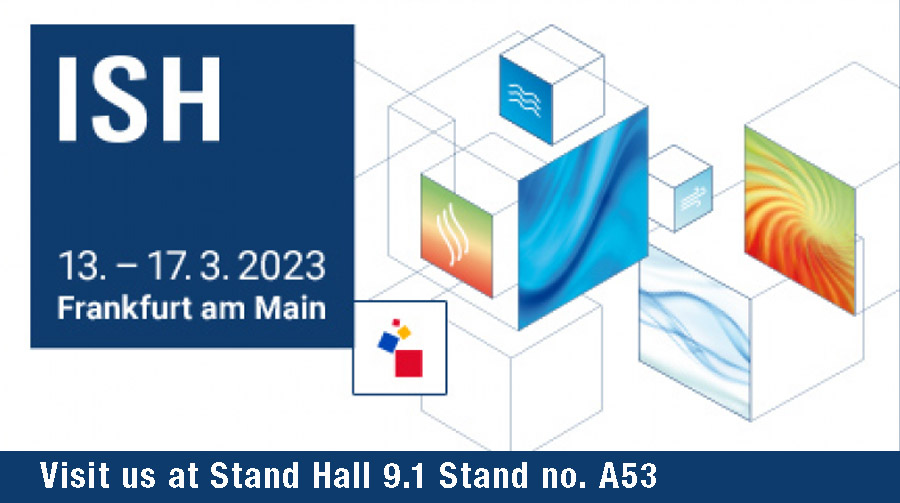

EXHIBITIONS 2023: MECOLPRESS AT ISH (GERMANY)

ISH 2023

ISH, the world’s leading trade fair for bathroom furnishing, air conditioning and energy saving comes back in presence after the online edition of 2021.

It will be held from 13 to 17 March 2023 in Frankfurt at Messe Frankfurt. This trade fairs covers many sectors.

We look forward to seeing you at our Booth, Hall 9.1, Booth no. A53

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Brass hot forging: from the mechanical technology to the hydraulic one with me series presses

Metals hot forging is a reliable and repeatable process which allows to obtain components with high mechanical properties, minimizing the raw materials consumption.

Over more than 50 years Mecolpress has been at the service of its Customers, providing the best forging technologies that allow to maximize the products quality and the related productivity.

Not always changing means improvement, but to improve you need to change

Mecolpress is committed every day to sharing experiences with its partners to follow a common path with the aim of overcoming the performance limits of existing production processes.

It is not the strongest of the species that survives, nor the most intelligent one, but the most responsive one to changes.

Exclusively from the merge of the complementary activities:

- Development of innovative technologies;

- From consolidated experience in the hot forged parts production, the way for barriers overcoming in the productive processes can be born;

- Increase of production capacity;

- Improvement of product quality;

- Reduction of raw material consumption;

- Reduction of energy consumption;

- Reduction of resources consumption (lubricants, cooling water,…).

The experience shown in this article is related to the brass hot forging

and more precisely to the passage from the mechanical to the hydraulic technology (Mecolpress ME Series). The product subject of the evaluation is the body of a sphere valve with dimension 1” and ½. Even if it may seem a standard and consolidated product, each customer has his own design and specific features.

Mecolpress has collaborated with an Italian industry-leader company to the production of the new die and to its industrialization. After two working days and proactive information sharing, by using our ME hydraulic press, we have reached:

- Production capacity more than doubled;

- Material consumption minimized of about 6.5% thanks to the flashfree forging;

- Improvement of the workability thanks to a more uniform internal conformation;

- Increase of product quality thanks to internal defects removal.

Even if at first sight a forged part may seem perfect, its integrity can be granted only from the internal analysis.

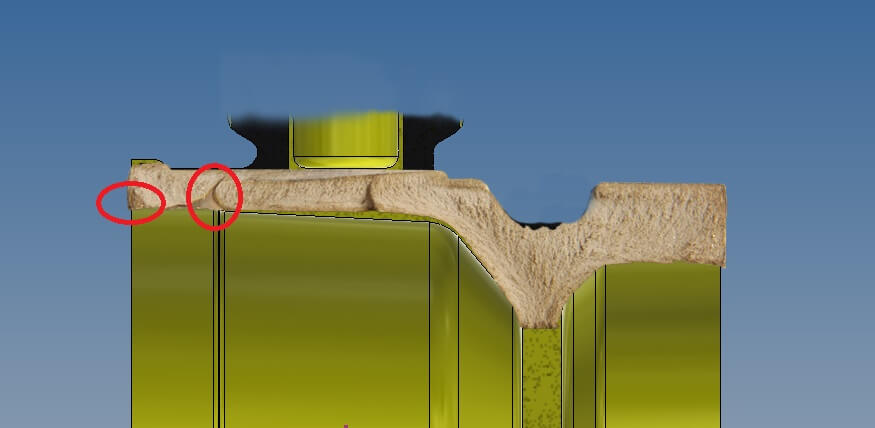

The material flow is unbalanced, the flowing speeds are not uniform, the material tends to detach from the die and to fill some areas before others (picture 1). When the flows meet each other again, they have such temperatures that they cannot be properly welded. The cold welding, indicated by the red circle, can cause problems during the machining phase, if it is included, even partially, in the surplus metal, or if during the assembly phase when the tightening torque of the front nut mechanically stresses the defected side.

Mecolpress hydraulic presses of ME Series, even without any previous simulation numerical analysis, allow to set the correct sequence of part forming according to the material flow dynamics.

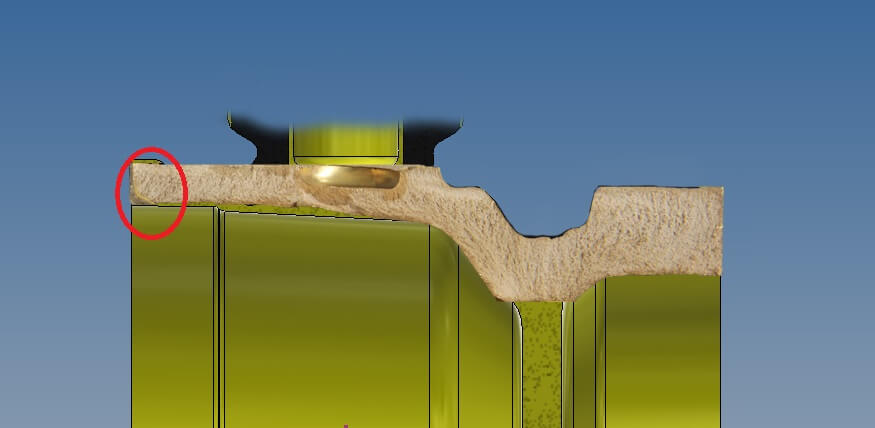

Thanks to this precious pre-forming function a progressive modification of the penetrations of the 3 punches has been applied and this has leaded to the desired result: the repositioning of the defect in a marginal zone (picture 2).

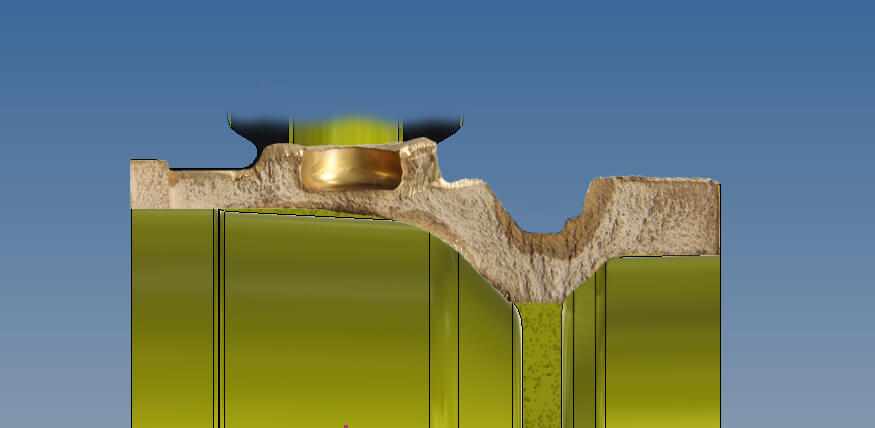

Then simple modifications to punches shape were taken into consideration in order to totally eliminate the cold junction (picture 3).

Two really efficient working days, product industrialization with new dies and more than 5500 good parts in the boxes, ready for the machining tests! A thank goes to our Customer for the precious collaboration, a thank to our team for the availability and speed of action and a thank to our hydraulic ME press that tirelessly, once again, allows to overcome the production limits and to permit a great improvement!

Wait!!! And what about energetic consumptions?!?! We are collecting data… a little patience… in the next article you will be informed about everything!

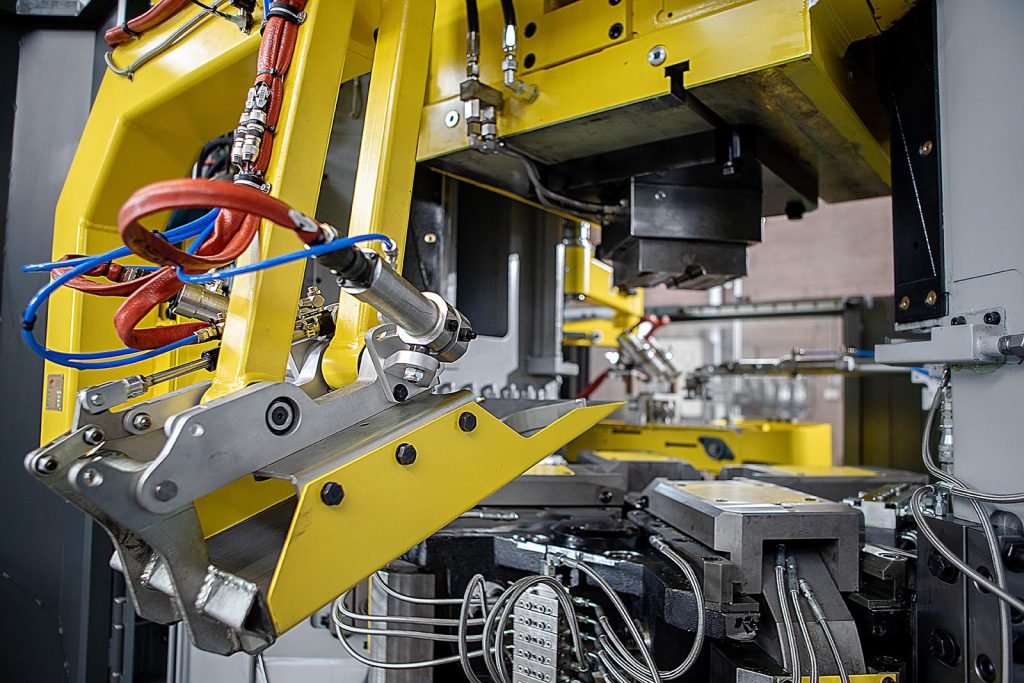

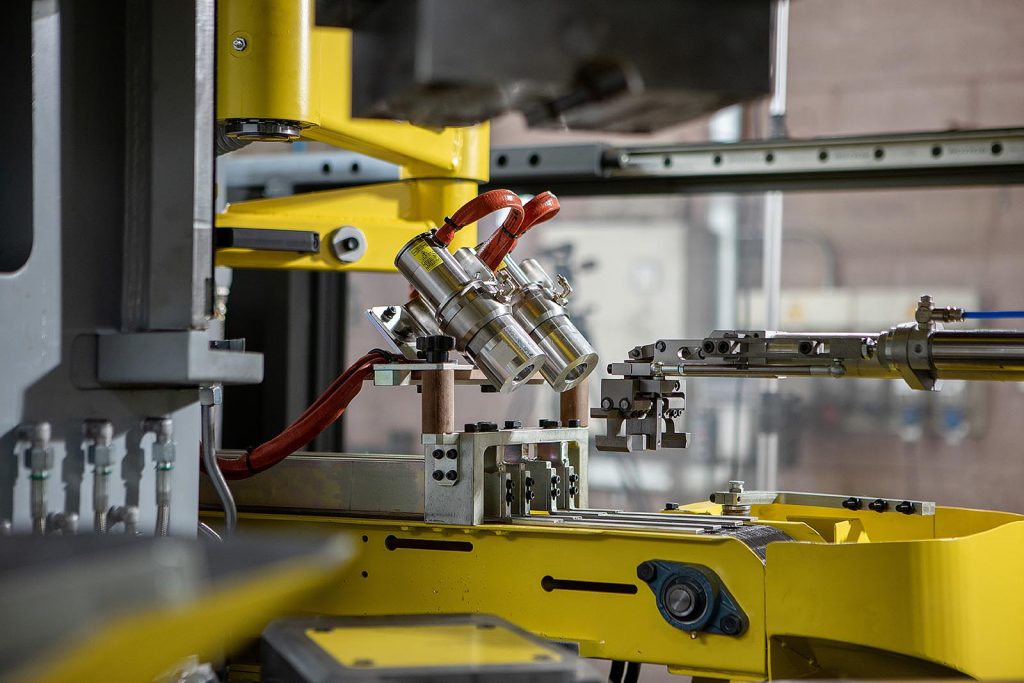

SEO/320: THE MECHANICAL PRESS ADDRESSED TO THE MODERN FORGING

The new continuous and discontinuous cycle mechanical press

Mecolpress is proud to introduce the new model of continuous/discontinuous cycle mechanical press for hot forging, size 320 tons.

This press is designed to improve the features of all the previous machines in the size range from 200 to 360 tons. Finally just one single press will be able to guarantee the performances of the historical SEO/27 CVE-CS or SEO/36 CVE-CS presses, and it will be the new mechanical SEO/320 press, indeed!

The experience acquired in more than 50 years of activity brought us to analyze every day the forging needs of many worldwide Customers. The main topic that emerges is that the greatest force capacities are needed to deform new materials, high alloys\without lead that are considerably more high-strength.

The result is a totally innovative press that includes all the improvements that Mecolpress applied over the recent years.

SEO/320 press was born to satisfy all the new productive needs demanded by the ongoing changes in the world of “modern forging”.

Recurring problems for a forger

If you are a forge manager or an owner of a forging factory, it surely happened to you that, to satisfy your Customers request, you brought your presses to the higher limit of the performances. Consequently one of the following situations will surely happened at least one time::

- breakage of the gears, and in particular of the teeth;

- breakage of the transmission shafts;

- maintenance on bearings and clutches….

Forcing you to unexpected machine stops, with all the related inconveniences\additional costs!

Solutions proposed by Mecolpress

Machine downtimes cannot totally disappear. We must remember that we are talking about mechanical presses that forge metals at very high temperatures and that can be subjected to overloads! But these can be drastically reduced.

”Why often we say that years ago the machines did not break down?”

The answer is easy! They were sized and studied specifically for the productive needs of that time that do not coincide with the modern ones any longer!

Mecolpress answer to the new required performances in the forging operations is the new SEO/320 press that is what each forger needs today!

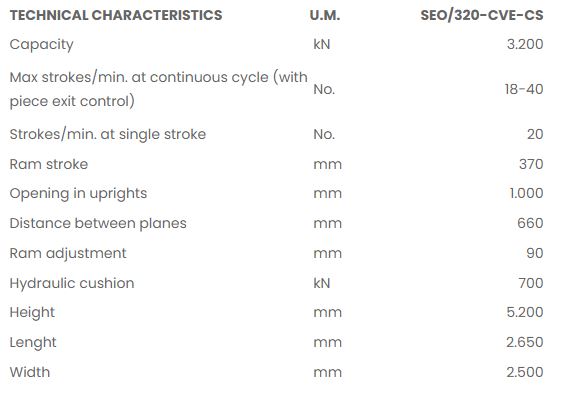

Technical characteristics of mechanical press SEO/320

- The machine has a monolithic structure in welded steel in order to ensure the maximum stability and duration over the year.

- The gears have a total innovative structure and extremely simplified that does not consist only in the dimensions increase, as you might think, but it consist of a series of improvements that allow the machine to work to the maximum performances without any breakage risk.

- The cushion was simplified, with the removal of the manual adjustments and of the mechanical parts generally subjected to wear.

- The flywheel was developed to guarantee enough deformation energy even at low turns. This particular characteristic is very appreciated by who has to forge the material requiring low deformation speeds.

- We have paid close attention to the ergonomic aspects: the operator can set up the tooling of the machine very quickly and without excessive efforts. Therefore you will find the equipment without tight spaces with wide visibility and, above all, safe and reliable.

We summarize in the following table the main technical characteristics of the new SEO/320:

An opportunity for the forgers

Mecolpress offers to every potential customer the possibility to inspect at least one version for each machine model at the production site based in Flero (Brescia). As a matter of fact, the main versions of the most requested models are always in production.

This results in an important advantage for you Customer because we are offering:

- the opportunity to see/experience the new machines with the support of our specialized personnel at your disposal to clarify any doubts or curiosities;

- A very competitive delivery time In case of purchase!

EXHIBITIONS 2022: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2022

Castforge Exhibition from 21 to 23 June in Stuttgart.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 21 to 23 June 2022 Mecolpress will be in Stuttgart at Castforge (Stand 5B57).

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2022: MECOLPRESS AT BIEMH (Spain)

BIEMH Bilbao 2022

This event will be held at the Bilbao exhibition centre from 13 to 17 June 2022.

Mecolpress will present its latest technological innovations regarding metal forging.

Besides Spanish companies also international ones will be participating in this event, operating in sectors such as: metallurgy, welding, articles and equipment, machine tools, technological solutions, and much more.

You can find us in Pavilion n°5 Stand D34

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

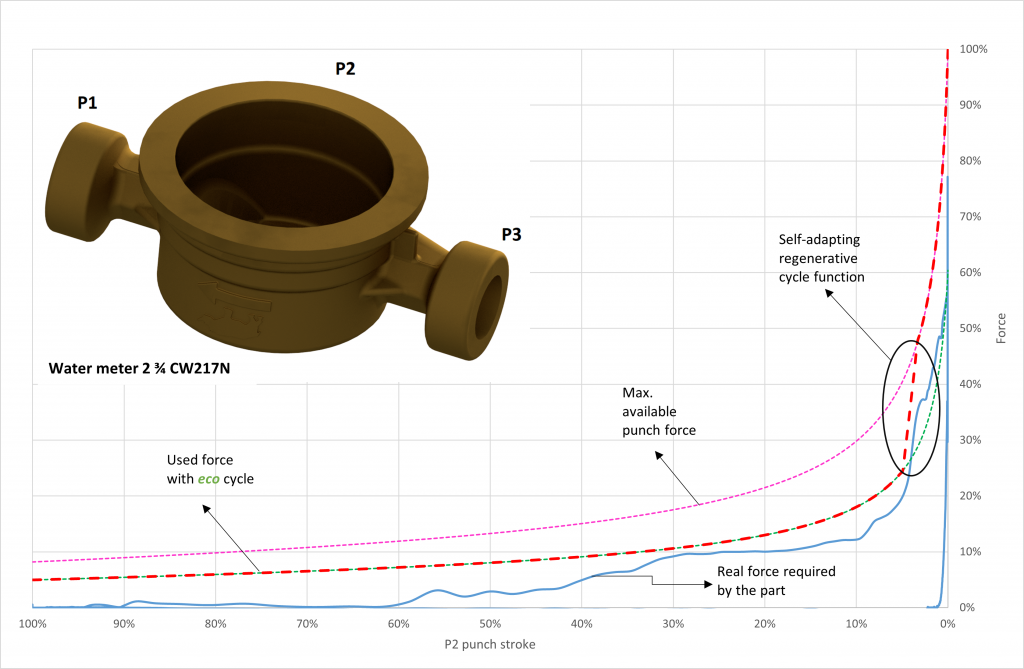

HYDRAULIC PRESS, Mecolpress leap into a new eco-green modality

Main features of the new ME eco-green Hydraulic Press

Mecolpress S.p.a. is glad to introduce the new improved features of ME family hydraulic presses, born from the need to offer to the Customers a more flexible and performing machine in terms of product quality and energetic consumptions.

We are currently proposing the family of ME presses having the die closure force that is in the range from 100 to 500 tons (as standard equipment) and with a minimum side punches force of 30 tons that can achieve up to 350 tons. Each of these last ones has completely independent operation, adjustable speed and set-able movement phases (forward-stop-backward); depending by the type of part to be forged , the hydraulic closure cylinder allows to apply the necessary forging force also before the dies contact.

The new presses can be fed by one anthropomorphic robot for the billets loading and one synchronized unloading arm for the forged products that eliminate the set up difficulties of the traditional past technologies; regarding the fumes suction, after a careful analysis of the actual state of the art, we have implemented and optimized the system making it more functional and effective.

The fume suction hood collects the emission very close to the sourcing point decreasing any possible spread into the press cabin, granting to the operators the best inside view of the process and reducing the oil collection and its possible overflow.

In this regard, the machines of the new series are integrated with the walkable grids that surround the press and prevents the eventual drip on the floor of the working area.

The hydraulic presses can be supplied customized with optional equipment according to the production needs.

For example, one of the punches can be oriented with the coring angle that is different from the classic 90° configuration , allowing in this way the realization of particularly complex shapes, like y-joint or filter body.

Other possible configurations are of new ME eco-green Hydraulic Press are:

- the addition of a fifth vertical punch acting from under the die,

- the loading of one or two billets at the same time up to a maximum of four,

- the addition of a dies-holder arm lightening the machine tooling process,

- the addition of a quick dies changing system with hydraulic locking,

- the addition of an induction dies heating system which the machine is particularly compatible with,

- fire extinguishing system integrable with the machine.

Moreover the main innovation is related to the energy saving achievements if compared to the previous series.

From 2022 all the ME presses can minimize autonomously the energy amount that is needed to produce the desired forged part: the press learns automatically the optimal pressure to be addressed to each forging punch: ECO cycle (settable from the control panel). Furthermore, during the movement of each forging punch, Calipso control software optimizes the time in which it is necessary to switch to the maximum achievable pressure (regenerative self-adapting cycle function): all the press parameters will be consequently harmonized according to this requirement.

This behavior represents the key economic and competitive advantage for the press user that can save up to 50% of the total installed energy without losing or reducing the punches force and can optimize the forging process parameters in order to minimize the energetic consumptions. To do this the operator direct intervention is no longer necessary. The operator is not required to have a long term experience or particular skills : he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!