HYDRAULIC PRESS, Mecolpress leap into a new eco-green modality

Main features of the new ME eco-green Hydraulic Press

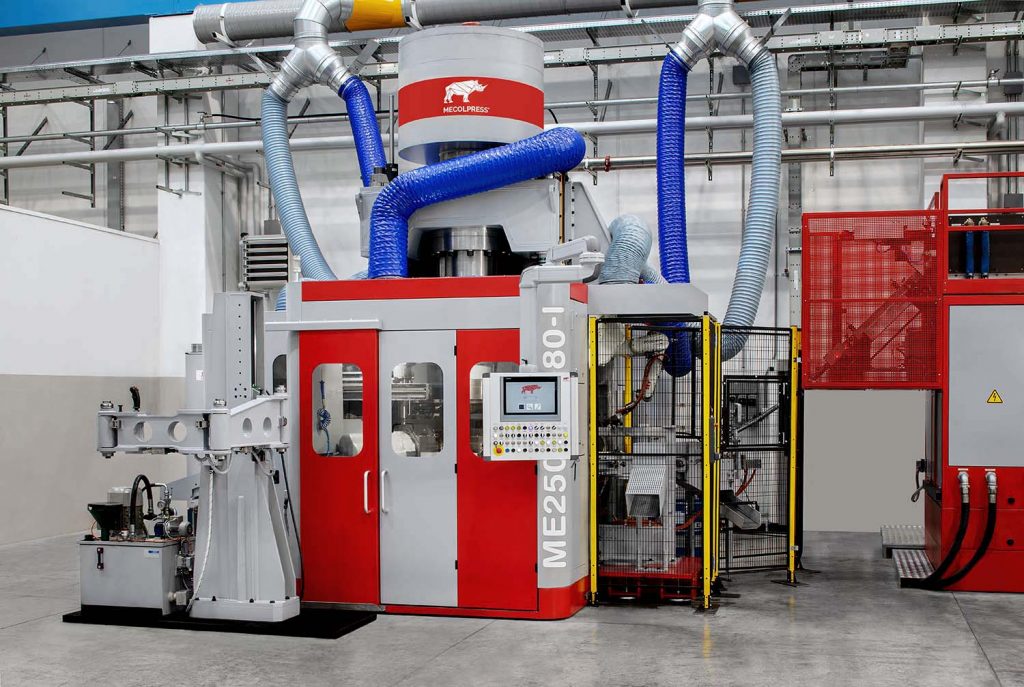

Mecolpress S.p.a. is glad to introduce the new improved features of ME family hydraulic presses, born from the need to offer to the Customers a more flexible and performing machine in terms of product quality and energetic consumptions.

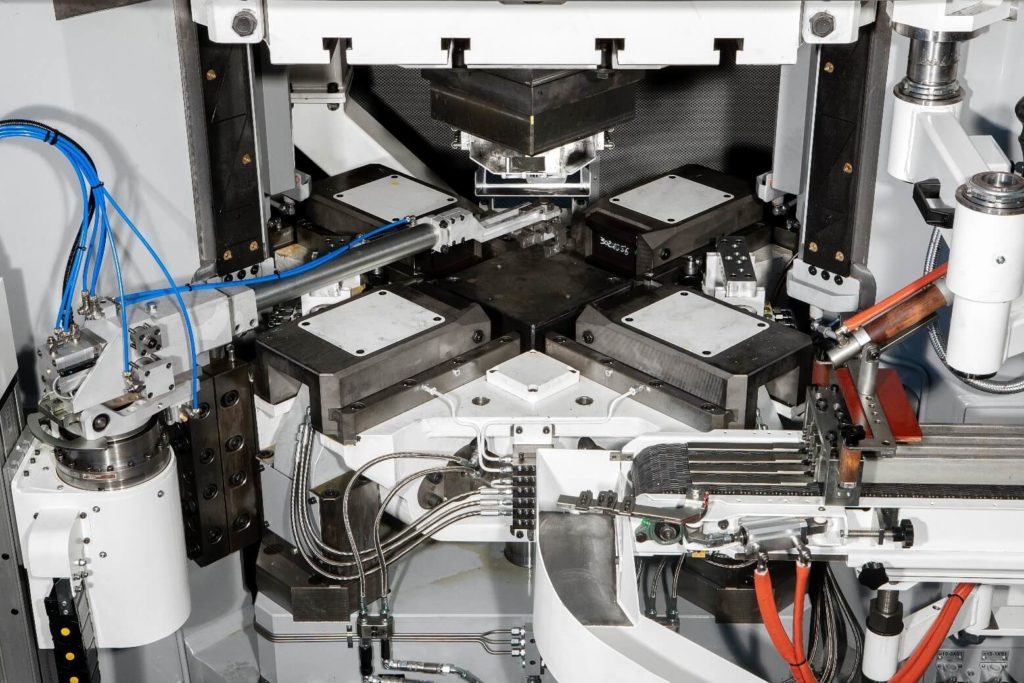

We are currently proposing the family of ME presses having the die closure force that is in the range from 100 to 500 tons (as standard equipment) and with a minimum side punches force of 30 tons that can achieve up to 350 tons. Each of these last ones has completely independent operation, adjustable speed and set-able movement phases (forward-stop-backward); depending by the type of part to be forged , the hydraulic closure cylinder allows to apply the necessary forging force also before the dies contact.

The new presses can be fed by one anthropomorphic robot for the billets loading and one synchronized unloading arm for the forged products that eliminate the set up difficulties of the traditional past technologies; regarding the fumes suction, after a careful analysis of the actual state of the art, we have implemented and optimized the system making it more functional and effective.

The fume suction hood collects the emission very close to the sourcing point decreasing any possible spread into the press cabin, granting to the operators the best inside view of the process and reducing the oil collection and its possible overflow.

In this regard, the machines of the new series are integrated with the walkable grids that surround the press and prevents the eventual drip on the floor of the working area.

The hydraulic presses can be supplied customized with optional equipment according to the production needs.

For example, one of the punches can be oriented with the coring angle that is different from the classic 90° configuration , allowing in this way the realization of particularly complex shapes, like y-joint or filter body.

Other possible configurations are of new ME eco-green Hydraulic Press are:

- the addition of a fifth vertical punch acting from under the die,

- the loading of one or two billets at the same time up to a maximum of four,

- the addition of a dies-holder arm lightening the machine tooling process,

- the addition of a quick dies changing system with hydraulic locking,

- the addition of an induction dies heating system which the machine is particularly compatible with,

- fire extinguishing system integrable with the machine.

Moreover the main innovation is related to the energy saving achievements if compared to the previous series.

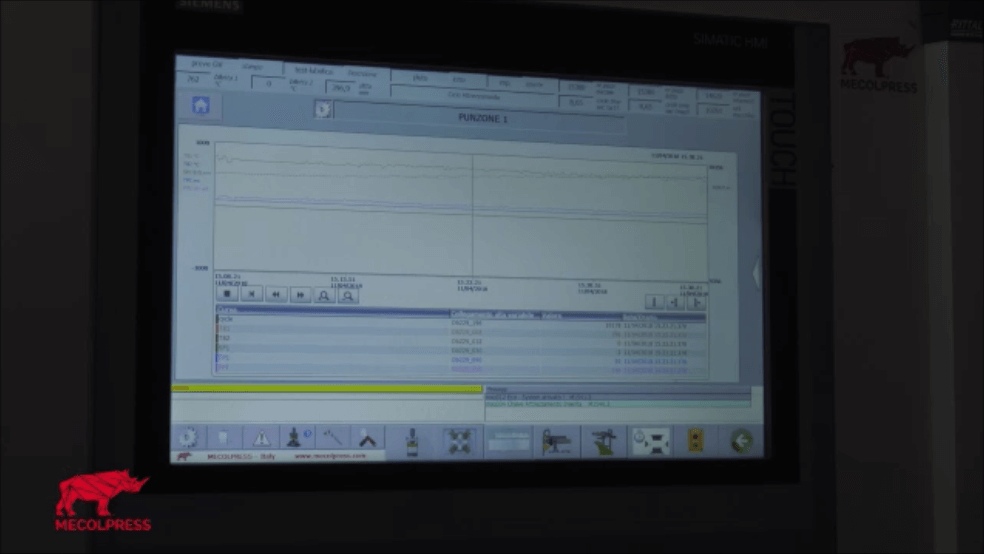

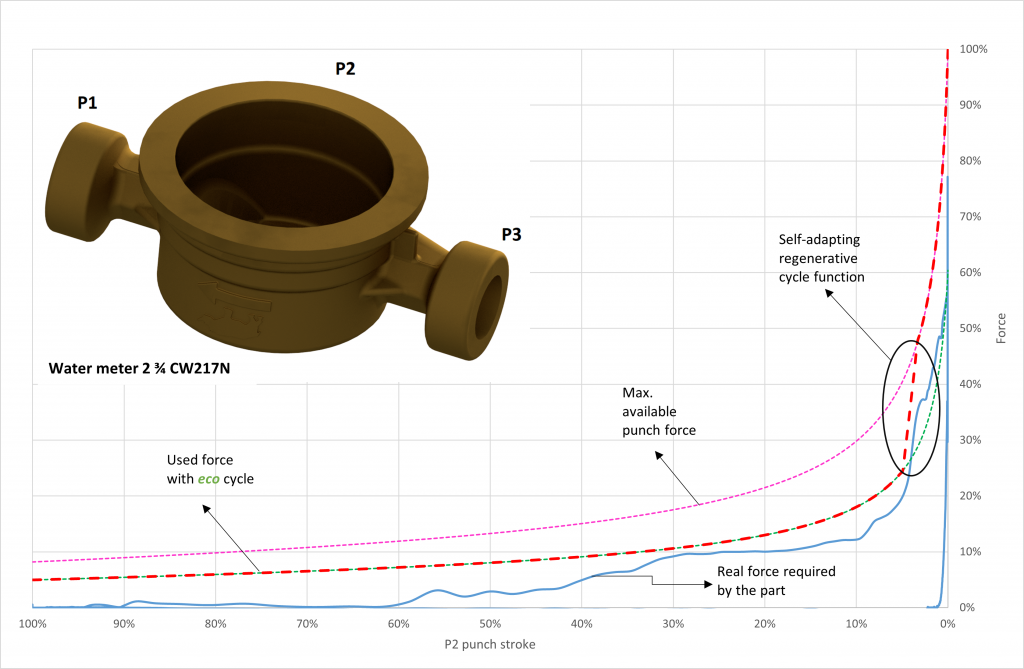

From 2022 all the ME presses can minimize autonomously the energy amount that is needed to produce the desired forged part: the press learns automatically the optimal pressure to be addressed to each forging punch: ECO cycle (settable from the control panel). Furthermore, during the movement of each forging punch, Calipso control software optimizes the time in which it is necessary to switch to the maximum achievable pressure (regenerative self-adapting cycle function): all the press parameters will be consequently harmonized according to this requirement.

This behavior represents the key economic and competitive advantage for the press user that can save up to 50% of the total installed energy without losing or reducing the punches force and can optimize the forging process parameters in order to minimize the energetic consumptions. To do this the operator direct intervention is no longer necessary. The operator is not required to have a long term experience or particular skills : he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

MECOLPRESS AT MECSPE 2021

THE EXCELLENCE OF TECHNOLOGY APPLIED TO INDUSTRY

It has been the most important event dedicated to innovations for the manufacturing industry and it counts 19 editions.

The fair will be held in Bologna from 23 to 25 November.

MECSPE, the main event in Italy on innovative technologies for manufacturing 4.0 industry promoted by Senaf, joins this outlook of restart and business confidence by following its commitment to support this sector and representing itself for 19 editions of over 2,300 exhibitors and trade associations.

This year’s appointment, rescheduled at BolognaFiere, from 23 to 25 November 2021, will have as its main theme “digitalization, training and sustainability”, subjects that visitors will be able to explore through 13 synergistic salons divided by thematic areas, demonstration of talent, commitment and creativity of Italian Companies.

A field, the industrial one, has always been supported by MECSPE which promotes fruitful collaborations between the various players in the supply chain, sharing visions and projects with them, as demonstrated by the historic partnerships with Confartigianato Meccanica and CNA Produzione.

At MECSPE 2021 we will exhibit the FPN 220 Turbo HS screw press.

This is the best evidence of the outstanding performances of the OSTERWALDER screw presses, part of by Mecolpress family from more than 20 years.

These screw presses are particularly suitable for processes where high precision\tight tolerances of forged components are required, for example in the production of gears. They are suitable for hot forging of steel parts, but also of all other materials.

The TURBO version allows to reach higher speed, increasing productivity from 20% to 40%.

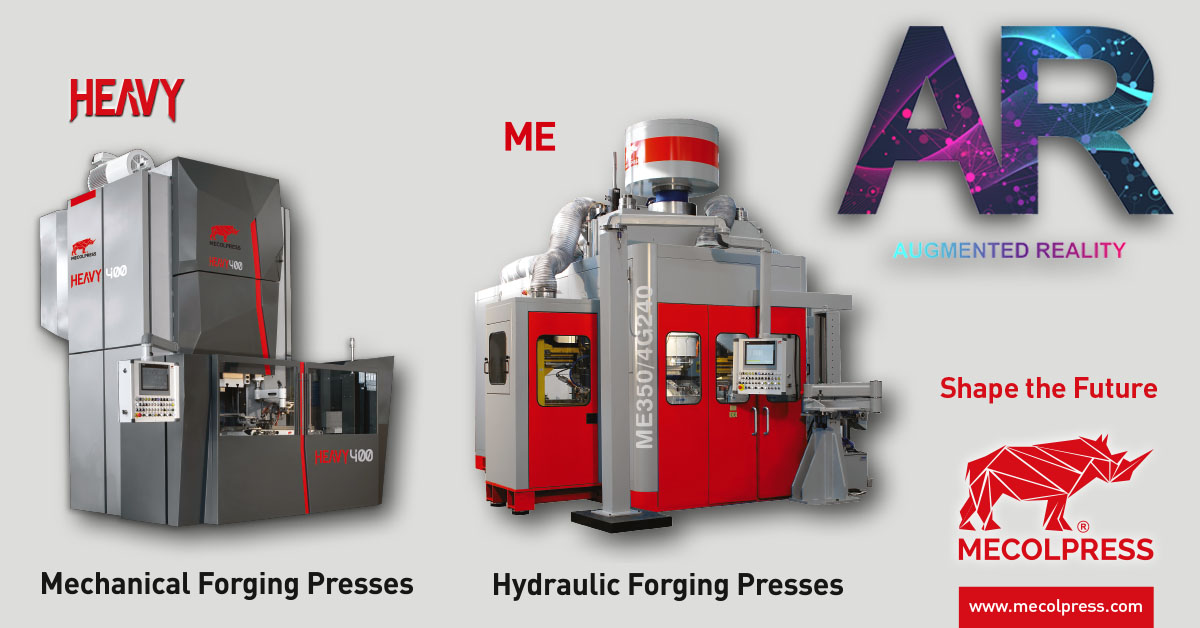

Augmented Reality, the press just a click away

In addition to the FPN Turbo screw press, it will be possible to view two other technologies thanks to the Augmented Reality: the ME Hydraulic and the Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

ForEMOst!

ForEMOst!

EMO is the worldwide exhibition of the machine tool, held in Italy and Germany, and that this year will take place in Milan at Fiera Milano Rho from the 4th to the 9th of October.

All the main international players of the manufacturing sector will take part in EMO MILANO 2021; so far there are more than 30 countries represented, covering all the segments that make up the world of the metalworking machines.

Undisputed leader in the trade fairs panorama, EMO represents the whole metalworking world in the best way, showing the best of vision and innovation.

Metal forming and metal cutting machine tools, robots, enabling technologies and automation, solutions for interconnected and digital factories, additive manufacturing will be among the key players of EMO MILANO 2021.

The exhibit is held in the entire Fieramilano Rho Exhibition centre, that can be easily reached with any transport means.

To guarantee visitors and exhibitors the participation in total safety in the exhibition, Fiera Milano Group has developed a Protocol for the safe conduct of trade fairs, in full compliance with the health rules and protocols issued at national level.

MECOLPRESS will participate with a “revolution” of the exhibition concept

Augmented Reality, the press just a click away

This technology allows to overlap multimedia information to the reality framed by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

A very powerful mean in the company communication field, and in this regard, the Augmented Reality has a strong impact on the customer experience, because it transforms the way in which companies interact with their customers.

In the trade fairs the Augmented Reality results to be very useful, both for the exhibitors and for the visitors who will be able to live a visual experience at 360-degrees.

Two will be the presses, chosen from the production range of MECOLPRESS, that will give birth to this innovative space of virtual reality, that will offer the possibility to see and to experience the functionalities of the represented machines.

We are waiting for you Hall 5 – Stand B29

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

Are you doubtful between mechanical press and hydraulic press?

Are you doubtful about the press to choose? Mechanical press or hydraulic press?

Ask to Mecolpress, you will have no more hesitations!

You have just got a new commission and you need a new press for hot forging. Are you sure that you can identify the press that best suits your needs?

Typical request

It often happens that a Customer, or potential one, comes to us with the part he desires to forge. Usually it’s about complex situations, very far from standard applications. That’s exactly why the Customer asks for our help and support.

If the Customer is not a newcomer in the forging world, he usually arrives in Mecolpress with clear and straight idea about the type of press he wants. But very often it happens that he will change his view after having the possibility to get in contact with our forging know-how!

You ask for a mechanical press but you need an hydraulic one!

For example, some weeks ago two different customers came to visit us bringing some sampling to be forged. They were sure to ask a quotation for a mechanical press, they realized instead that the right machine for their situation was a hydraulic one!

Both our customers had the chance to test new dies, only 4 hours were needed for the preparation and installation of the dies and to run some tests. Even though the furnace was not the best one for their kind of production, because it’s a furnace that Mecolpress uses for testing, the machine gave a flash-free part in only 4 hours, with a saving of about 30% of material and with a quality definitely superior than the one they could achieve using a mechanical press.

Moreover, it is important to take into consideration the limits of the mechanical press:

- Since the part is not balanced, the mechanical press should use all its possible force to forge it.

- Working in this way the risk to run into damages or machine breakdown becomes greater.

On the contrary, The ME hydraulic press can forge the part better. The forged parts which required more force used however less than 200 tons on a punch, therefore it consists of a forces distribution that is totally different compared to the traditional mechanical press.

Often the customer is skeptical towards the hydraulic press, but just because he is not familiar with it!

Find out more about the hydraulic presses

The hydraulic presses patented by Mecolpress are suitable for the hot forging of standard parts or special parts in brass and aluminum. The dies closure force is higher than the one of the traditional mechanical presses and the independent and controlled movements of the ram and of the extruders allow to hot forge also complex parts without flash.

These are oleodynamic presses provided with coring tools combinable till to a maximum of 5 punches (4 horizontal and one vertical) suitable for the hot forging of brass, aluminum, copper and other materials.

Compared to the traditional mechanical presses these presses have different advantages, including:

- Reduced vibrations and noises.

- No foundations are required.

- Higher flexibility: there are no mechanical connections between tooling and ram; this implicates that you can decide speed, force, position and movement sequence for each punch independently. The result is the possibility to decide how to let the material flow, this helps the part production with a better quality level.

- Ease of tooling: easy access to the forging area and automatic adjustment of punches strokes from the panel that cancels the mechanical adjustment on the spines (for example insertion of spacer).

- The press is easy and intuitive to be used even without a great experience in the forging field. Together with the machine a lifelong service via teleservice and phone assistance is provided.

Some practical examples about the choice for a hydraulic press.

- Hydraulic press ME150: this is a quite small machine and often we suggest it to who has no experience in the hot forging field.

- Hydraulic press ME 250: let’s get serious!

Example: are you undecided if you want to buy a 400t mechanical press or a ME250 hydraulic press?

If you have small and easily to force parts to be produced in huge quantities and in series maybe the choice of a mechanical press is the most suitable, but if you have a part that is lightly more complicated, probably you need an hydraulic one. In this case, we are sure that a test here in Mecolpress will remove any doubt!

- Hydraulic press ME from 450tons onwards: This press is more efficient, more cost-effective, it allows to save material, to increase the productivity, it is more convenient, more silent, no foundation pit is required and despite of what our competitors affirm, the energy consumption is not high. In fact, this consideration comes from the fact that just the installed power is taken into consideration.

Did you carry out a forging simulation and forging tests?

In order to choose the right press it is surely helpful to carry out a forging simulation, our technical office can support the customer during the process for choosing the machine with a software analysis of material flow, in order to carry out a sort of “virtual pre-acceptance” of the plant.

Once that the forging simulation is successfully over, then the next step is a real test in our factory. Indeed we have available machines devoted for the forging tests, this is a very important aspect for the customer that often gives him the possibility to invest in a more aware and motivated way. Touching the forged part doesn’t leave no room for doubt!

Being able to satisfy and fully understand the customer needs, to demonstrate and propose our most suitable solutions with concrete tests thanks to the machines and toolings we have available in Mecolpress for the forging tests is for us matter of pride.

Friction Srew Press – MECSPE 2020

Mecolpress will partecipate in MECSPE, at Fiere di Parma from 29 to 31 October 2020.

We exhibit the FPN 220 friction screw press.

For 19 editions MECSPE has been the greatest event focused on innovations for the manufacturing industry.

The numbers of Mecspe:

135.000 SQUARE METERS

56.498 VISITORS

2.306 EXHIBITORS

12 THEMATIC SHOWS:

360° innovation, the fair offers a complete overview of innovative materials, machines and technologies, Industry 4.0.

This event offers an interesting moment of meeting between companies, professionals and associations to build new opportunities for the manufacturing market.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

This ticket will allow you to access the exhibition area, participate in conferences, attend the demonstration areas and special initiatives of Mecspe 2020, and take advantage of free parking.

You can find us here:

MECOLPRESS

Hall 8 Non-ferrous materials and alloys, Stand M24.

For the 2020 edition of MECSPE, Mecolpress exhibits the FPN 220 Friction Screw Press

The screw presses like the one we bring to MECSPE are used for the hot forging of brass and steel parts, or with any type of material in general.

They are characterized by the production of solid pieces, or that require multiple forming steps.

Find out more by consulting the screw presses category on our blog.

We are therefore waiting for you at MECSPE!

MECSPE

Location: Fiere di Parma

Address: Viale delle Esposizioni, 393A – 43126 PARMA (PR)

Date: 29 – 31 October 2020 – Thursday, Friday, Saturday

Opening Hours: 9.00 – 18.00 (Thursday and Friday); 9.00 – 17.30 (Saturday)

Visitor entrances: Reception Sud, Est, Nord, Ovest

Visitor Parking: adjacent to the entrances

https://www.mecspe.com/en/magazine/

The excellence of technology applied to industry.

HOT FORGING PRESSES INTERVIEW WITH MECOLPRESS

Company manufacturing hot forging presses.

We report an interview of the digital magazine Easy Engineering of 28 April 2020.

Established in 1969, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. Up to today, Mecolpress has developed and installed more than 1.950 presses, at over 400 customers all around the world, used for forging brass, aluminum, copper, titanium, steel. The current production site in Flero, in the highly productive area of Brescia, takes up a 30.000 square meters surface, 10.400 of them are covered and employees 55 people, reaching a turnover in 2018 of 11.5 million Euro.

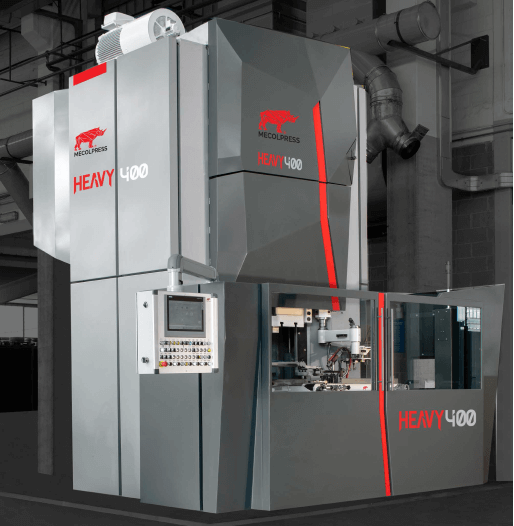

In 2019, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

Easy Engineering: What are the main areas of activity of the company?

MECOLPRESS: At the beginning all efforts were concentrated on brass hot forging field; in the time, also through the acquisition of the historical brands Osterwalder and Dellavia in the screw presses section, the variety of machines that we design and produce is now so wide and complete to satisfy the most different requirements of the customers: for each specific material, shape and quantity to be forged, we are in the position to offer the most suitable solution.

Mecolpress is today the only company among the manufacturers of presses for the hot forging of brass, aluminum steel, copper, titanium, with a so complete production program.

Our present production program consists of:

- TDS: direct drive with electrical servomotor;

- Dellavia and Osterwalder: Traditional disc friction.

PG Knuckle joint presses

for calibration and coining of parts.

Presse Meccaniche Eccentriche

- SOV and SEO/F: for the vertical hot forging;

- SEO and HEAVY: for forging with horizontal cores, in single or continuous cycle.

for forging brass and aluminum parts without flash.

- PO: single station;

- S: multiple station, rotary table with hydraulic motor;

- E: multiple station, rotary table with electric motor.

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..).

E.E: What’s the news for 2020 about new products?

MECOLPRESS: At the end of 2019 Mecolpress presented at EMO fair in Havvore a brand-new series of eccentric presses, named HEAVY, which defines a new standard for the hot forging of brass.

A machine concept that offer highest durability and reliability together with an innovative software system that allows the maximum control on the process and the a very easy operation.

E.E: What are the ranges of traded products?

MECOLPRESS: As a manufacturer with an own wide range of products, the additional equipment that we simply trade is limited to ancillary machines, to offer complete forging lines (delivering a finished part from the input of a raw material bar) to those customer that prefer to have a turn-key plant from one source.

Typical traded machines are: billets heating furnaces, forging dies, sand blasting machines.

E.E: At what stage is the market where you are currently active?

MECOLPRESS: Since our machines are dedicated to a very wide panorama of applications (from house building to automotive, from gas control to biomedical) there are always new developments in these sectors.

This is for us very stimulating because we are constantly involved in the design of new solution, to support our customers with the most suitable equipment to manufacture parts that are chancing in the shapes, in the alloys and in the technical requirements.

E.E: What can you tell us about market trends?

MECOLPRESS: In the past our customers were mainly subcontractors, producing many different kinds of parts for the most differentiated OEMs. We see now more and more companies that are interested in bringing back into their own activity the hot forging process, to have full control over the entire production line. And also, the subcontractors that still exists, are increasing in size, in capability, and in specialization: they are requested to be much more accurate, reliable, more flexible and fast in changing production and technologies.

For these reasons, the machines that both our customer types (the subcontractors and the OEMs) need, are machines that can easily switch from one application to the next, and that can record and control really in depth every aspect of the production process. The user is therefore becoming more an engineer, that study and program the process in advance and then let the machine run autonomously, instead of an operator that has to stay full time at the machine, checking and adjusting the settings.

E.E: What are the most innovative products marketed?

MECOLPRESS: As above indicated, one of the most innovative products that we offer today is the new range of Heavy presses.

In parallel to this, we are widening the offer for the ME hydraulic presses which are designed to forge net shape parts. These machines are extremely versatile, can communicate in two directions with the company ERP software to exchange production data, recipes, preventive maintenance information. And are also able to automatically detect a non-conforming product and separate it from the good ones. This makes the ME forging presses a fully automatic system, that does not require operators to work but also does not need regular presence of quality control staff to check periodically the output.

E.E: What estimations do you have for 2020?

MECOLPRESS: At the end of 2019 we planned a very aggressive budget of sales for the 2020, and supported it with several activities and strategies, from the participation to many international shows, to the production of machines for stock, to grant to our customer very fast deliveries.

Unfortunately, due to the Covid-19 virus spreading, many commercial activities had to be reprogrammed or postponed. We are now investigating the world markets to assess what will be the customers’ propensity to invest for the remaining months of this year. We are very optimistic that we will in any case be able to reach most of our targets also thank to the availability of machines in our workshop, which is allowing us to complete deliveries in this year of machines ordered in the second and third quarter.

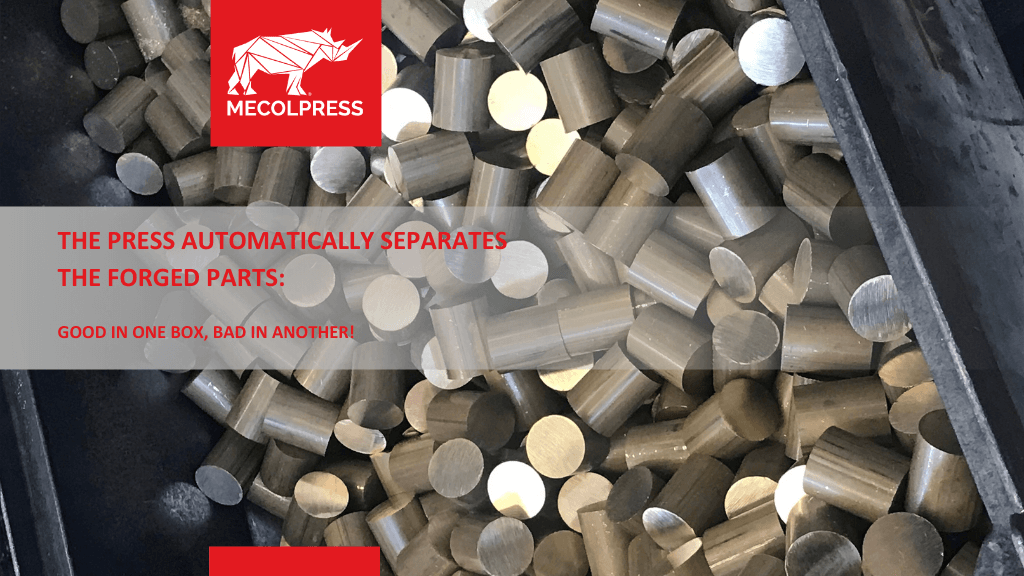

THE PRESS AUTOMATICALLY SEPARATES THE FORGED PARTS: GOOD IN ONE BOX, BAD IN ANOTHER!

Differentiated unloading of the forged pieces

The press automatically separates the forged parts and divide them into different boxes. The press has become intelligent!

The differentiated unloading of the forged parts is an interesting function that Mecolpress provides by default on all hydraulic presses, but it can also be added as an option on eccentric mechanical presses.

Hot forging for higher quality of forged parts

The metal hot forging differs from the cold one because it allows you to obtain high quality pieces through an important deformation of the starting material. By working brass, copper, titanium, steel and aluminium by means of hot forging presses, in fact, it is possible to produce particular shapes, even with complex geometries.

The metal hot forging therefore allows to obtain parts that are more resistant than those obtained through other production processes.

In particular, metal hot forging can increase the strength and resistance of the products. For these reasons, the production of hot forged pieces guarantees specific advantages in their mechanical characteristics compared to those produced with other technologies such as casting or mechanical machining with chip removal.

The hot forging, compared to the casting processes, allows to obtain mechanical characteristics and surface appearance of superior quality. We at Mecolpress know it well, so much that we have made “Technology of Shape” our motto.

The piece produced must therefore be perfect, its quality must be certified. For this reason, Mecolpress has designed a system that allows the press automatically separates the perfect forged parts from those to be evaluated as they may not be such.

Why is it so important that the press separates the perfect forged parts from those to be evaluated?

From the automotive sector, the Lean production method teach us:

- Companies can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

- The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

One of the most recurring needs in our customers is to have an ever more intense control of the forging process: the machine must be able to control as many parameters as possible important for the forging process, record them to make statistical predictions on the deviation from the optimal production, carry out checks.

Mecolpress offers a series of forging presses that fully meet the needs described above: the ME hydraulic series.

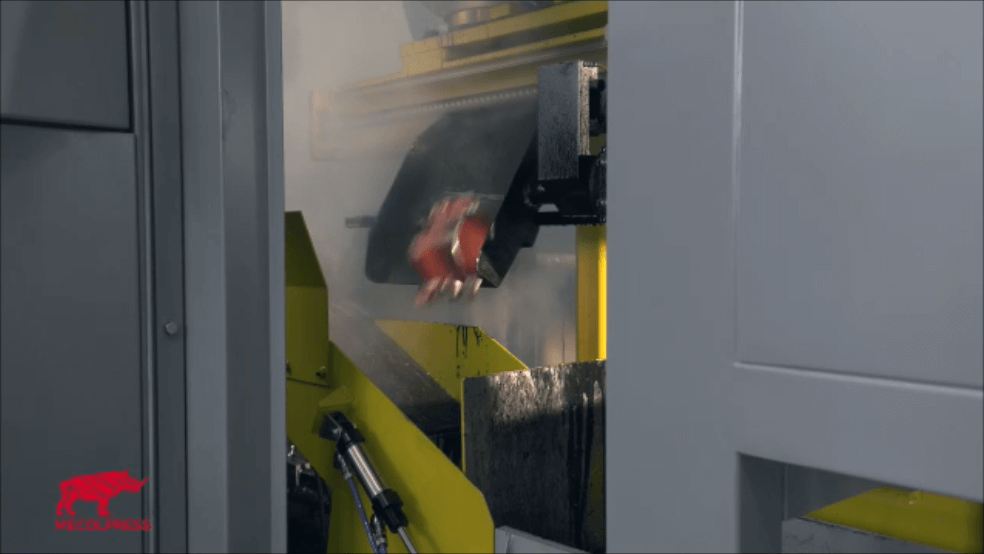

The hydraulic presses can control numerous process parameters and on these manage the logic for rejects or collect the measured values for statistical analysis. For example, they can control:

- the temperature of the billets to be loaded,

- the coring punches penetration time,

- the punches real penetration force,

- the final position reached by each punch.

Here you can learn more about the most important process parameters that hydraulic presses are able to evaluate.

The machines of the ME series have the credentials to be competitive in a modern and controlled forging field; they operate at their best on medium / small batches, thanks to their flexibility.

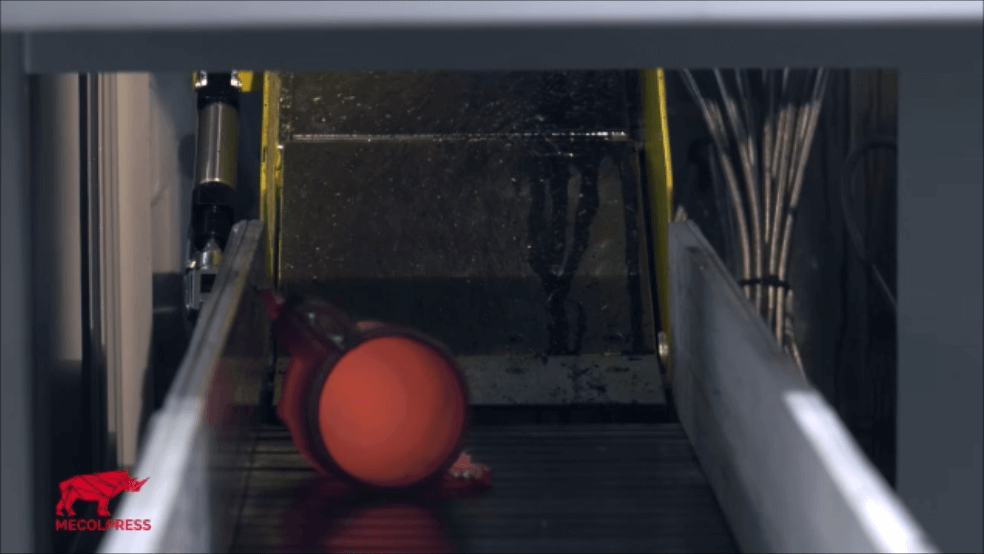

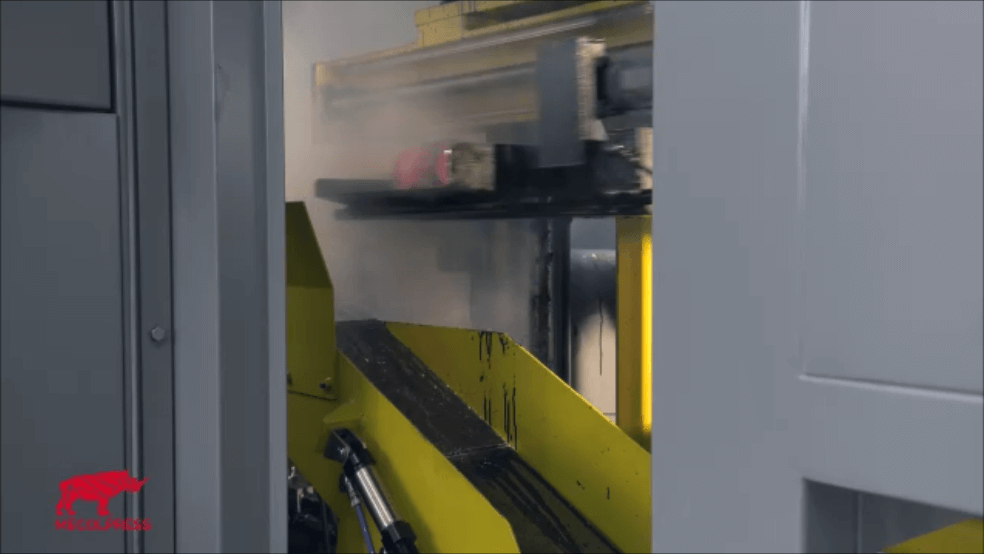

In this video we show how our hydraulic presses perform the differentiated unloading of the forged parts:

The pieces that do not fully comply with the process parameters set by the operator and analysed by our powerful Calipso software to control the forging process, are unloaded in a separate bin.

For the customer this operation translates into an important saving method:

- Less waste of time,

- Less material / pieces to be discarded,

- Be sure that the forged piece complies with the required characteristics,

- Get perfect shapes.

Another company based in Brescia chooses Mecolpress hydraulic presses.

With regularity and continuity, Mecolpress gains new Italian customers, the hydraulic press is confirming to be the winning choice.

Case Study: How we acquired the latest customer from Brescia

We report the case of a new customer based in Brescia that we have just acquired, an interesting case study to understand which are the necessities of the companies working in the hot forging sector and how Mecolpress provides answers.

It is the case of a company established in the international market for the very high quality of its production, consisting mainly of mini valves, valves and fittings for the sanitary and heating sector. This company has its own brass hot forging department, developed to cover the 100% of the forged parts needs; the recourse to very few and highly selected external suppliers happens just in case of particular peak of volumes.

The presses equipment of this company consists of 5 machines, always full of work: 3 more traditional and “dated” (eccentric mechanical presses of the historic producer Rovetta, that now no longer exists) and two more recent little hydraulic presses of a particular type, proposed by an European producer.

Knowing better the company, now customer of us, we could appreciate right from the beginning some undisputed features:

- Advanced transfer machines;

- A working method focused on the precise and deep knowledge of all the productive processes;

- A forward-looking vision on the continuous training of all the personnel that is involved with the management regarding the strategic decisions and that creates a uniform a close-knit group;

- A quality department having knowledge, methodologies and instruments not only for the examination of the parts but also for the evaluation of the method used for their production.

During various meeting both at customer’s and Mecolpress site, we had the opportunity to present them our complete range of presses and in particular the functionalities of our hydraulic presses of ME series.

Mecolpress method

The customer wanted to test us, taking advantage of the Mecolpress strategy of having a selection of presses almost ready for delivery, for carrying out forging simulations with two parts of their production range on the specific press of their interest.

The result was that, thanks to the constructive collaboration of both teams (the customer and the Mecolpress ones), in just 9 weeks from the decision of beginning with the simulations, we could:

- Carry out the forging simulations of the two parts to be tested;

- Manufacture the related forging dies;

- Carry out forging tests with two dies (in manual and in automatic cycle, since Mecolpress has 2 high-performing push-type gas furnaces;

- Dismantle and demolish one of the old presses of the Customer;

- Deliver at customer site in Brescia a new ME150/4G62 hydraulic press, exactly the same one the customer saw and tried.

Why the company under consideration chose Mecolpress?

We thank the customer for the trust and for having tested us, and we are particularly proud that even they, as other customers, after having bought and used the hydraulic presses of our competitors, have chosen to purchase Mecolpress for the future.

The decisive points for this new positive result are in short:

- Mecolpress can offer to the customer not only any kind of new presses, but also exceptional expertise in the maintenance of old presses, of other manufacturers (in this case Rovetta).

- Mecolpress hydraulic presses, both for mechanical and construction project and for extremely developed software, offer to the user an incomparable ease and usage flexibility.

- Choosing Mecolpress, the possibility to conclude an investment in very short time, and to see it becoming rapidly productive; who wants to invest has no time to wait and must be helped to be competitive as soon as possible!

Would you too like to try a forging simulation?

Don’t waste your time,

test us!

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!

HEAVY SERIES MECHANICAL PRESSES

Mecolpress, at the EMO exhibition in Hannover which took place last September, officially presented the new series of eccentric continuous cycle mechanical presses, the HEAVY series.

Based on the experience accumulated over 50 years of designing and manufacturing presses for hot forging metal, we have succeeded in creating a totally renewed mechanical press.

We are sure that our new project will mark the beginning of a new era for hot forging!

What are the main strengths of the new HEAVY mechanical presses?

-

- A structure that is certainly innovative and modern, more robust and designed to simplify control and maintenance;

- Fully revised die automation and lubrication;

- Our innovative hydraulic cushion, the Soft-Impact, which allows to achieve important results including for example the possibility of vibrations reducing;

- The updated version of our intelligent Calipso software, for the analysis of the production process and for predictive maintenance.

Let's analyse the features in detail:

STRUCTURE

The structure of the machine is made in such a way as to separate the dangerous area (moving parts and die area) from the areas accessible to the operator for adjustments and ordinary maintenance, through front protections and soundproofing material casings, as required by CE standards.

Directly on the vertical part of the forging area, the fume extraction is obtained through metal ducts with connection to the customer’s centralized system.

The control unit for centralized lubrication of the press, the regulators of the pneumatic system and of the die lubrication system and the electrical equipment are inserted in large protected cabinets and easily accessible to the operator, not reached by the fumes and the oil of die lubrication .

The assembly of the main parts to the machine is designed to simplify inspection and maintenance.

COMMAND GROUP

It includes a compact transmission coaxial to the eccentric shaft including:

– Combined flywheel and reduction unit;

– Combined Hydraulic Brake-Clutch Group, equipped with progressive piston to mitigate shocks and transmission vibrations due to engagement and braking;

– Control valve of the Brake-Clutch group with progressive engagement and braking control;

– Double gear coupling between eccentric shaft and transmission to avoid the transmission of shocks from the crank mechanism to the control unit;

– Main motor with encoder and closed loop control, allows the slow movement of the press for tooling, “Inching mode”.

The flywheel motor system has been completely revised to obtain better resolution and precision in speed control, greater reactivity in the recovery of energy after forging.

A safe speed limit control is foreseen with open front protection, during the set-up phases and a check of a possible excessive slowing down of the machine (for example due to a too large billet).

The motor cooling is constantly ensured regardless of the motor speed, this allows to always guarantee maximum performance.

We have provided an interesting option: the energy that the motor returns to the inverter during the slowdown phases, is put back into the network and not dissipated in heat; in practice it translates into a lower consumption of electricity!

SLIDE

Also the slide has been revised, we have foreseen a motorized adjustment of the vertical light and an extraction bar with hydraulic control.

The sliding skids are oriented radially to the machine axis to reduce the variation of the tolerances with changing temperatures.

The hydraulic system for protection against overload is also inserted in the slide, which is essential for forging on the bottom.

GE EQUIPMENT

– Possibility of mounting the lower punch also with “SOFT IMPACT” cushion,

– Water cooled upper die holder,

– Up to 8 points of lubrication from the lower die holder,

– Up to 4 points of lubrication from the upper die holder,

– Easy equipment change. It is extracted by unlocking the top with pistons that allow extraction on a ball guide.

– Possibility of mounting the motorized adjustment of the punch stroke.

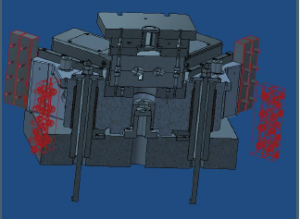

For the HEAVY400 the GE26 is foreseen, which has the following specific features:

– Dies 290 x 290 mm

– 110 mm punch stroke

Thanks to our Extruder Group you can save up to 40% of the material compared to the full forging modes! Check out the details here

“SOFT IMPACT” CUSHION

1000 kN hydraulic cushion with complete electronic management, it allows to check the punch height, in addition to limiting the mechanical shock due to the impact between the dies.

The Soft Impact cushion is an important innovation that we have been making for a couple of years, and that is proving to be truly appreciated. Read here to learn more about how it works.

BRCE LOADING DEVICE

The 2-axis rotary loading arm driven by brushless motors has the load angle of the clamp at 45 °, aligned with the dies centre;

The 400 mm vertical stroke allows you to manage any type of equipment without manually changing the position of the arm.

PBSE DISCHARGE DEVICE

The discharge chute has been designed to avoid dents to the forged part; driven by a motor brushless, the unloading arm allows automatic adjustment of the position.

DIE LUBRICATION

We have provided up to 20 lubrication points and 2 dies blowing points, an open and flexible configuration for each type of die and tool.

Also interesting is the possibility of adjusting the amount of oil from the panel, without need of manual adjustments on the machine and on the control unit.

From every point it is possible to blow air to clean / cool the die before every lubrication.

The press is able to warn in advance when it is necessary to fill the hydraulic unit, in order to avoid a machine stop due to lack of fluid.

A digital sensor allows the control of the fluid temperature, the operator can start the production only when the oil is at the correct temperature, an essential requirement for a correct and constant lubrication.

An inverter for pump speed adjustment prevents overpressure peaks and oil dripping when the pump starts with oil still cold; automatically adjusts the oil flow rate according to the quantity needed for use; prevents overheating of the oil in the control unit.

Our lubrication system, unlike the systems marketed up to now, eliminates the problem of the quantity of oil usable for each individual nozzle.

Competitive lubrication systems load a limited amount of oil into a tube and then blow it off with compressed air.

This ensures that 70% of the sprayed lubricant is used only in the first moment of lubrication, while in the remaining cycle the quantity of lubricant decreases until it is completely zeroed.

On the other hand, our lubrication system allows continuous and constant mixing directly at the exit point of the pipe, through our system we can cool and lubricate the dies from the same pipe without affecting the programmed oil quantity.

ELECTRICAL CONFIGURATION

The 24vcc circuits are protected by auxiliary electronic devices, able to provide a quick diagnosis of any short circuits or overloads (also through Teleservice).

This is a very interesting aspect because it allows a greater reliability of the system and a service life up to 10 times greater than normal technology!

The cables are in PUR, protected by steel sheaths and silicone protections against flames, specific for use even in environments deemed aggressive.

OPERATOR INTERFACE

The Operator Panel is a 15 ″ Siemens Touch Panel to better manage machine data, you can save up to 1000 recipes! And have an alarm history with up to 10,000 events.

Obviously, through the proper configuration of our software, you can receive valuable reports to carry out preventive maintenance.

Another practical example is the notepad function, thanks to which the operator can then write important information and his personal notes, added to each production recipe.

It is possible to obtain a production report, a secure management by 4-level password with autologon function, and much more.

Finally, the movable panel allows close controls on the machine, possibility of movement and programming with front or rear open protection, close to the die (eg die lubrication).