Hot forging of the brass without flash, a success case

Brass hot forging and its application sectors

The hot forged brass pieces are used in many sectors, including, for example, clothing and constructions industry. The belt buckles, the zippers and door handles are all examples of parts produced with this material and obtained through hot forging presses.

Among the different application sectors, however, the one that sticks out mainly is the fluids control and hose fittings sector.

- Taps and fittings pieces,

- Valves for LPG tank and high-pressure gas,

- Ball valves for water, gas and oil,

- Watermeter bodies,

- Junctions for both the normal and floor heating, these are all brass pieces.

This type of product is currently affected on the market by a very strong competition of the Countries in which the manpower is cheaper and where probably in some cases a brass alloy is used that responds mainly to the local necessity and to the temporary availability, rather than to satisfy the international quality standard. To produce this kind of pieces in Europe, saving competitivity on the market represents therefore a challenge for many companies.

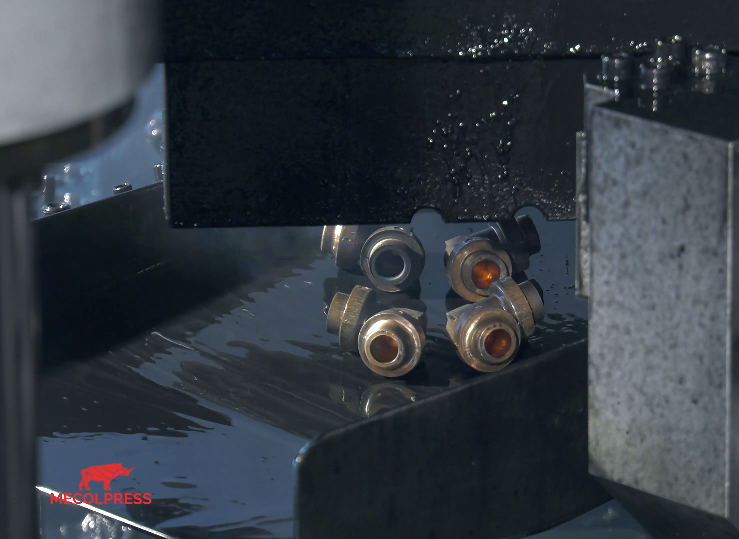

Hot forging without flash four brass parts at the same time

Speaking with a customer of ours who has the productive headquarter in Europe and who produces brass pieces, we could experience his real difficulty to remain on the market. From here comes the idea to find a solution that could allow him to increase the productivity and to reduce considerably the wasting material for sparing on the costs.

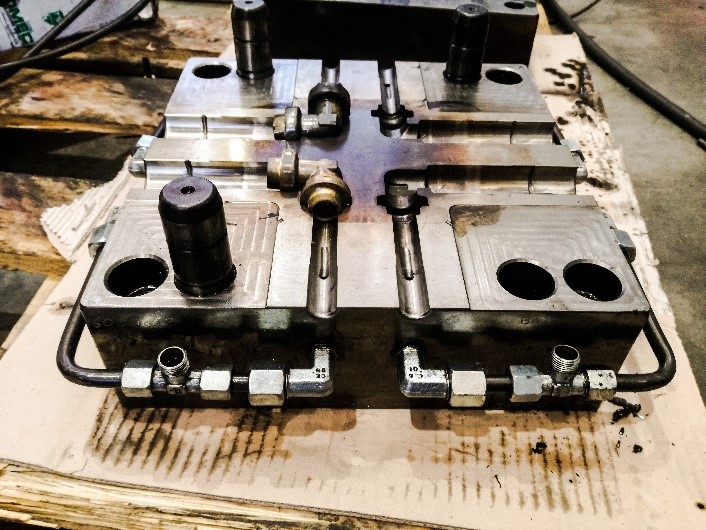

Our staff in collaboration with the technical office of the customer has identified then two different dies: one for the production of a hose junction connection and another for a curve of 90°. These new dies have been developed to take advantage of the potentiality of our hydraulic presses of ME serie of forging without flash and the result was to forge 4 parts at the same time.

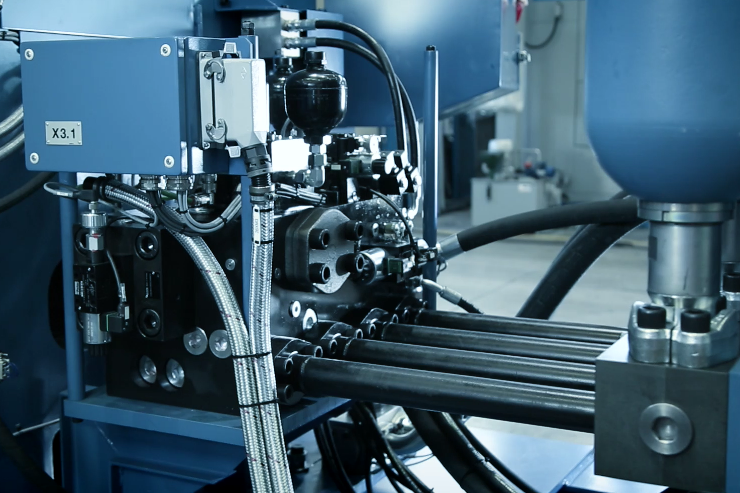

In order to obtain this result, it is necessary to provide one of our standard hydraulic presses, such as the ME250/4G100, with some optional accessories (including also the billets loading system), that are conceptually simple but extremely well-performing.

This system is different due to its strongly innovative characteristic, since at the moment just the Mecolpress presses can provide this result (forging 4 pieces at the same time without flash) that surely brought great advantages also to our customer in terms of marginality on the product cost.

Through this specific press for the brass forging, it is possible to produce 4.500 parts at hour on average without flash.

This case study shows how it is possible to find solutions in the concrete and proactive collaboration with the customer that satisfy in the best way the specific productive necessities of that company and for its own specific interest.

Beyond the press: great care for all the manufacturing segments

The reasons why you should appreciate (and prefer…) the modularity

In the planning and realization of different forging lines there is a common denominator, and it is the main machine, the heart of the entire project: the press.

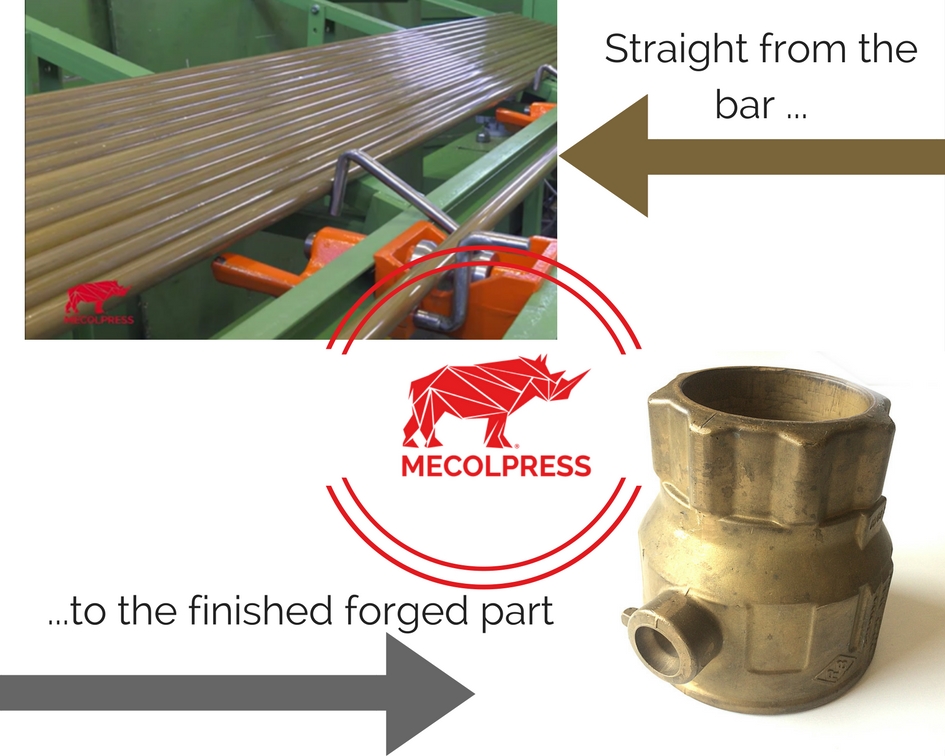

Even if it concerns aluminum or brass forging, the press manufacturer must have a broad view, that can contemplate the entire process, from raw material bars to the finished part. An optimum press has to be born “conceived” in such a way that allows it to be able to work in synergy with the other components of the line, in order to guarantee to the user the maximum efficiency and minimum wastefulness.

The most important manufacturer’s feature that every customer who buys machineries looks for is reliability: the certainty of providing themselves with a product that “performs”, that gives satisfactions and no worries. Obviously, the moment of the initial choice of the machine is crucial, and it is determined by understanding the variety and variability of customer’s necessities over time and by the manufacturer’s competence satisfying them.

And then, steps that cannot be considered “less” crucial will arrive: installation and activation of the machine, for example. These are moments you will spend calmly, if you have someone by your side that assumes wholly the responsibility to have delivered the machine, to have verified that it works during the entire working life of the machine, as expected by the costumer, since the manufacturer is present from the start up.

Putting effort into guaranteeing all this means to be completely “master” of their own technology and of all the components that compose the line, thought as many different “segments” of a whole. We all know that presses for working and going into production need accessories, like sawing machine, furnace, deburring machine…

The skilled press manufacturer knows how to give the right relevance to these segments, by addressing the customer to the most appropriate choice (both for technical characteristics and budget characteristics) for him, by offering the most correct solutions, even if these are supplied by the manufacturer himself or if these are reachable directly from the customer by other specialized manufacturers.

The habit to think and to study every single “segment” of the forging line so that it contributes to the best, in its peculiarity, to the line efficiency has a name: modularity. The numerous satisfaction “stories” of the “Top performer” customers indicate the modularity as the most efficient way to go.

How many elements, realistically, is the press connected to? The list is long:

- traditional gas heating furnaces,

- Induction heating furnaces,

- graphitizing machines,

- arms or external Robots and of third party for loading/unloading of the machine,

- trimming presses,

- sandblasting machines,…

In the face of a so articulate system, the experience shows us that the “compactness” is not enough.

There is no doubt that setting up a line according to the modularity criterion will request:

- Time and patience;

- active consultation of the manufacturer;

- the need of being informed and updated on the market proposals

- Once the choices are made and components are purchased, arranging the suitable places to place them.

But let’s resume exactly from here. The possibility to “save” spaces, indeed one of the main subjects of the offers of compact lines manufacturers, seems not to be a small advantage.

However, combining many specific machines in just a “compact” solution for the above-mentioned advantage to save space risks to compromise the production results. Unfortunately, the matter of fact is that a break of just one component is enough to stop the entire “compact line” activity. So, the risk is: I have optimized the space, but the banal breakdown, for example of a blade of the shearing machine could cause the stop of the total production. At that point, having saved space will not be a great consolation, unfortunately.

The style of modularity belongs traditionally to manufacturers who knows thoroughly the problems and matters that who forges must face every day. Who has this kind of knowledge also knows well that the fact of being able to intervene in a focused and independent way on every components of the line has no price.

The modular concept, that as we have already seen, provides to have the press in line but separated from the furnace and even not in line with the other machines (as, for example, the sawing-machine or the graphitizing machine, that working separately, can create “buffer” stock of semifinished parts along the line), it allows:

▲ The biggest flexibility: the customer can choose the components he prefers (gas or induction furnace, sawing machine or seaming machine…), changing them in the future to answer to new needs, and to adapt the line layout to a company that develops.

▲ The press, since it is independent from furnaces and sawing machine, can be used in the future for forging other types of brass alloy, or copper or aluminum.

If sawing-machine, furnaces and press are “melt” in just one machine, this is not possible.

▲ Every machine can give its best (a good sawing machine can cut more billets/hour than a press can print) and does not have to adapt to the speed of the slowest machine.

▲ The line will be able to be easily adapted to non cylindrical classic billets, but also, for example pre-bent, disc shaped, billets with special contour.

▲ The best efficiency: each machine is independent, the press can forge when the sawing-machine needs a blades replacement: on the contrary, when the die on the press is replaced, the sawing machine can continue to prepare billets.

A solid knowledge of the machineries is the fundamental base that allows the manufacturer to design and propose the best technical and economical solution for the customer’s needs. Since the manufacturer is specialized in the production of presses and since he is not obliged to provide with the press its own sawing/shearing machine and furnaces and not those of anybody else, will be able to suggest to the customer the best solutions to the specified needs.

The range of the proposal is very wide, and it is possible to range from new lines (in which each component is totally new and realized by the best specific manufacturer) to lines in which one or more parts are overhauled. But is welcomed also the costumer that, choosen the press manufacturer for trust and reliability reasons, then refers to him to have consultation and indications for the other components to add so to have a complete line, “ad hoc” both for the technical production requirements and for the “wallet” ones.

Regardless of your belonging sector: thermal-hydraulic, gas, automotive, railway, biomedical, special screws, clothing components, the modularity confirms always to be the winner, exactly for the flexibility that guarantees to the forging line and for maintaining its efficiency.

Complete Mecolpress Line for hot forging of metals

Complete line for hot forging of metals

Mecolpress has the abilities and the experience to develop complete forging lines.

We have designed and composed various forging lines, taking care of the whole project:

From the initial choice of the machines and related interconnections, to the installation and commissioning, taking full responsibility of the service and of the after sales warranty of the whole line.

Mecolpress therefore, in addition to in-house designing and manufacturing of the hot forging presses, is able to provide to the customer a full turn-key plant, from the raw material bars to the forged piece (including of course the eventual trimming, sandblasting…).

The productive core of the line is clearly one of our presses, being a mechanical or an hydraulic one.

In the video shown as example here below, you can see a line with a mechanical press of the SEO range.

Forging line with mechanical press SEO

Forging line with hydraulic press ME-G

The ME-G hydraulic presses are particularly suitable to be installed in a complete forging line.

Are machines specifically designed to be used in the hot forging of brass, but have already proved to be extremely flexible and therefore suitable for other materials as well, like aluminium.

With this kind of presses, Mecolpress has introduced in the year 2010 a fully new production method for the hot forging processes.

This technic, called “inverse extrusion”, allow to forge parts even with the most complicated geometries, where the deformation of the material is obtained by means of a pre-determined and controlled flow of material.

This is generated by a programmable advancing of the punches into the die, after that the pre-heated billett has put deposited in the die and this has been fully closed.

The ME-G hydraulic press can be connected and interfaced with:

- Bars sawing / shearing machines,

- Traditional gas or electric induction heating furnaces,

- Furnaces designed for the shearing of the hot bar,

- Automation arms or external robots and of third parties automations for the loading and unloading of the press,

- Flash trimming presses, sand blasting machines…

The interfacing possibility is very useful for example when, in case of an alarm from the furnace side, the press has to be put in a stand-by status and has to record the reason for the production interruption.

In turn, the ME-G can send to the furnace the information “start / stop billet feeding” and can exchange signal of operating status with other components of the forging line, as well as the production parameters with the customers’ own factory supervisor systems.

Soft-Impact hydraulic cushion for eccentric mechanical presses

A recent innovation by Mecolpress for eccentric mechanical presses.

Mecolpress proposes to equip the eccentric mechanical presses of an innovative hydraulic cushion, Soft-Impact.

Features:

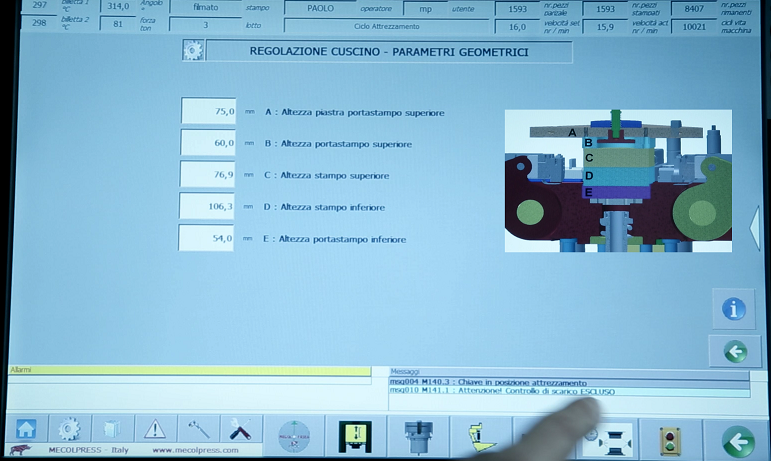

- It is a real hydraulic cylinder with a stroke sensor on the shaft;

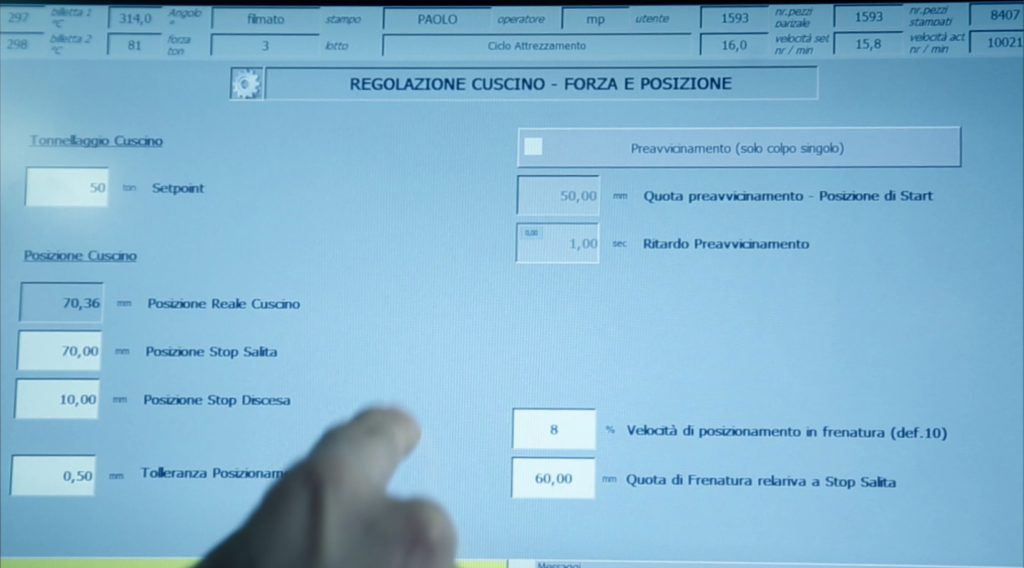

- Movements are fully programmable and controlled by means of proportional valves;

- Starts independently the down-stroke and then the punches move forward toward the die center before the upper die hits the lower one;

- Strokes adjustment from operator panel by simply inserting the desired dimensions and the data of die and die-holder heights;

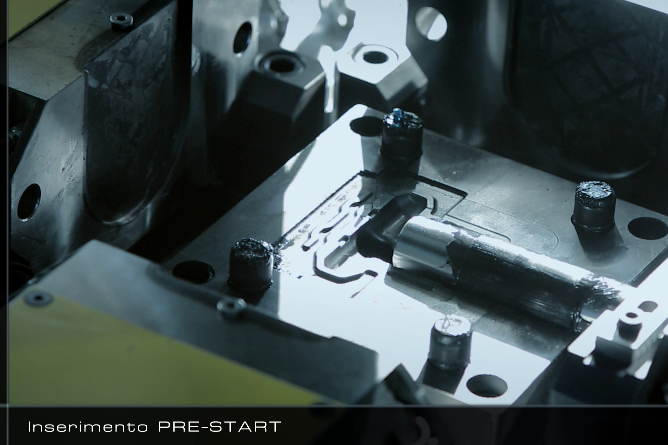

- As alternative, the function “punches pre-start” allows the punches to move close to the billet before the die closes and the forging begins.

- Dedicated hydraulic unit, separated from the machine clutch one.

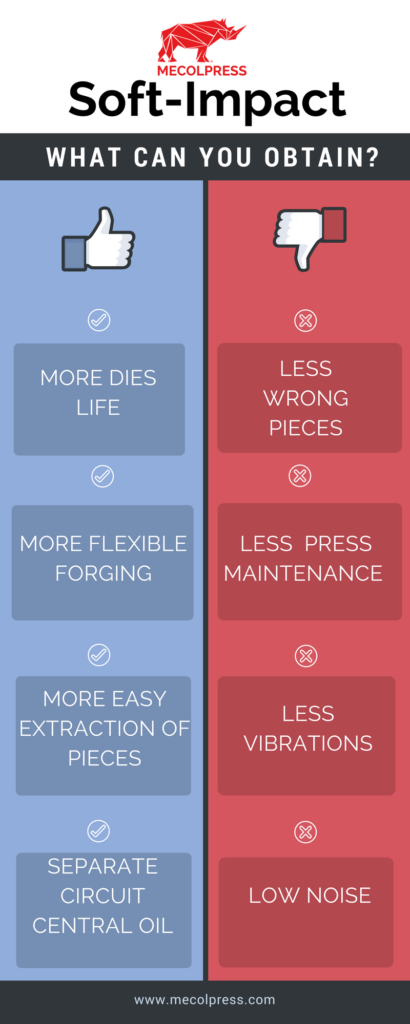

Thanks to the here above-mentioned features, the soft-impact hydraulic cushion allows the mechanic eccentric presses to achieve important results:

- Extremely simplified mechanical components;

- Precise adjustment from the operator panel of the start, stop and braking quota; all set parameters are saved together with the piece recipe;

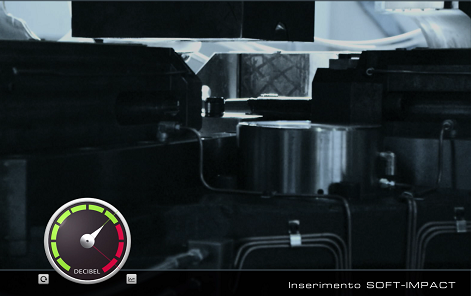

- The upper die does not crash violently against the lower one, because it “reaches” the second one while it is already in the descending phase;

- The control system automatically calculates the speed and the moment to start the cushion;

- When the material deformation begins, the punches are already in an advanced position decided by the operator (it can be saved in the piece recipe); when the die re-opens, the punches then go back beyond the quota of work start;

- Separate blocks modular system.

Benefits:

- Less and simpler maintenance;

- Ease of use, machine set-up and perfect repeatability of forging’s cycles;

- Reduction of vibrations, resulting in general benefits for the press and for the working environment;

- Reduction of noise;

- Increased working life of dies and pins;

- No complicated calculations or measures for the operator;

- Possibility of reduction of forging defects due to material that goes out along the empty punch channels and then is pushed inside by punches starting their stroke too distant;

- Ease ejection of pieces (having an extra back stroke) without penalizing the cycle time;

- The oil in the cushion control unit has its own independent circuit and does not mix with the clutch oil, usually dirtier.

The new Hydraulic Press 4.0 technology Intelligent Manufacturing

Discover the Benefits of Intelligent Manufacturing with Mecolpress Hydraulic Presses - Technology 4.0

Returning from the EMO Fair in Hanover, our new hydraulic press ME 100.

Mecolpress has always been part of this event, and this edition has also been an important event for us, where we met many visitors from all over the world.

The digitization of industrial production has been the leitmotif across all Emo 2017 booths.

Industry 4.0 is a major process of global interest and also Mecolpress has presented its new ME100 hydraulic press, offering solutions for Industry 4.0 and integrated production.

La nostra nuova proposta è una pressa idraulica compatta SuperVeloce per la forgiatura di pezzi complessi a basso peso che assicura un altissimo livello di produttività, possibilità di stampare parti con forature multiple, forgiatura in singola o doppia figura, in verticale, in orizzontale e con ogni angolo billetta.

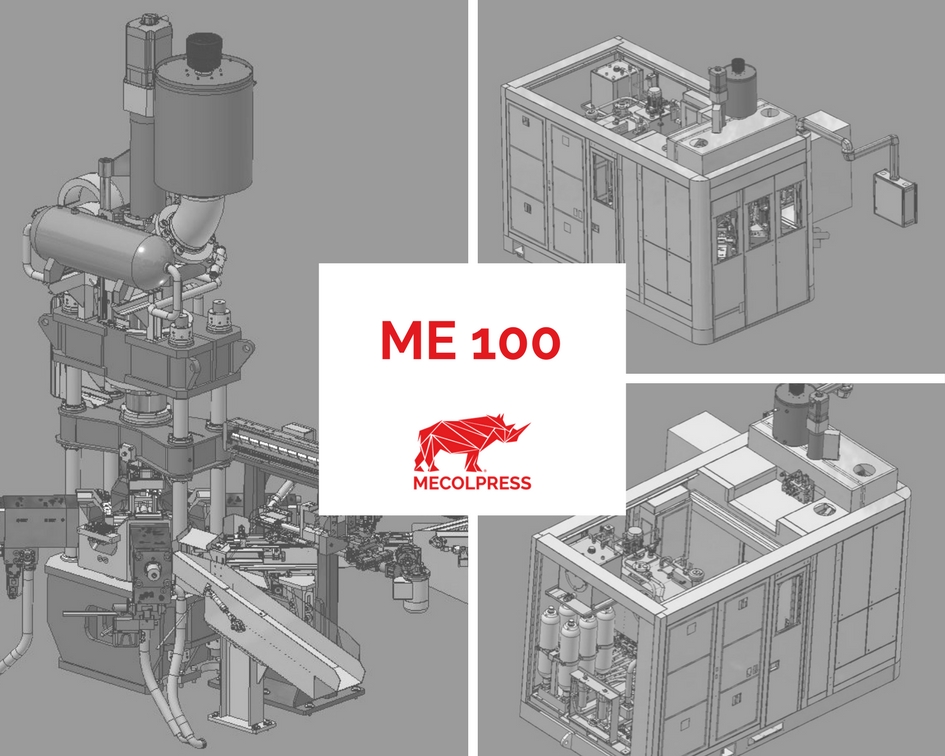

Our new proposal is a super-fast compact hydraulic press for the forging of low-weight complex parts that ensures a high level of productivity, the ability to forging multi-punched parts, forged single or double shape, vertically, horizontally and with each billet angle.

Mecolpress has developed this innovative machine, which will become part of the well-known series of presses ME, will have the code ME100-4L-30. This machine responds fully to our customers’ Industry 4.0 requirements and the general market for a press that features high precision features along with flexibility, ease of configuration and control of the production process.

Another important news was The brass bars heating+shearing furnace GBH5000, which allow great precision and modularity, in fact to connect both to new and existing presses, hydraulic, mechanical and screw.

Like all our ME series hot-press hydraulic presses, the new ME100 also allows you to control the speed, sequence, stroke and strength of each punch, enabling some of the most complicated forms to be forged flash-less.

The production phases are programmed and monitored to get the best shape.

Read more about the 4.0 requirements of our machines..

Mecolpress also puts you at your disposal a powerful production analysis software tool that allows you to perform statistical analysis of the forging process. This greatly reduces the waste of time and resources due to the production of non-conforming productions.

Read more about our software Calipso Statistical Process Control.

We are very pleased with the success of the news we have presented, but we are already committed to new extensions of our range of presses and also accessories for special applications. Follow us to stay up to date.

We thank all the visitors and the staff who took part in the event. We remind you of the next appointment:

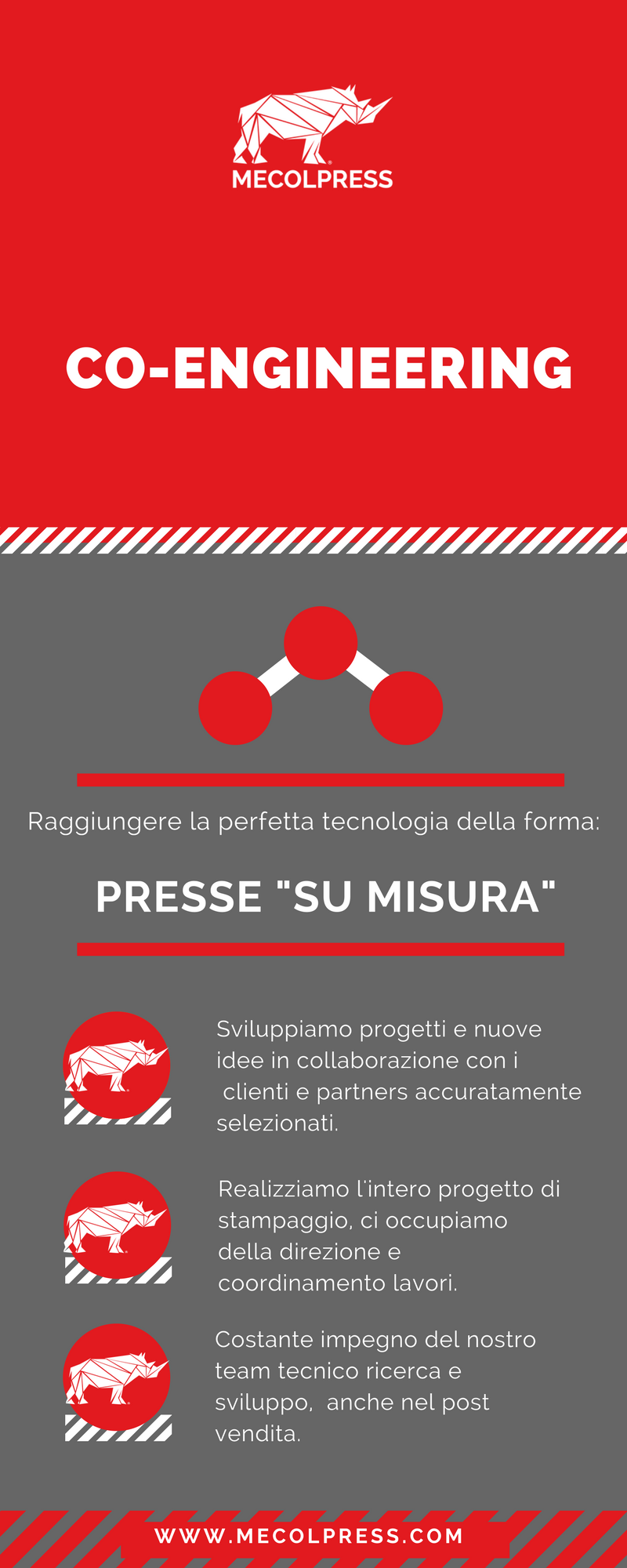

CO-ENGINEERING TO DEVELOP MECHANICAL PRESSES

Co-Engineering makes it possible to create customized Mechanical Forging Presses and Hydraulic Presses

Mecolpress manufactures mechanical presses, hydraulic presses, used mechanical presses and used hydraulic presses, carefully revised, developing projects and new ideas from a close and constant collaboration with their customers and carefully selected partners.

This allows you to make great initiatives based on the professionalism, seriousness and trust of those who collaborate, sharing the best of the technological skills and design capabilities of everyone.

Mecolpress designs and constructs totally a complete range of hot forging machines such as: mechanical presses, hydraulic presses, friction and electric screw presses, trimming presses and knuckle joint press.

Through a co-engineering activity he also succeeded in offering complete forging systems that could include:

- Anthropomorphic robots

- Design of pneumatic and electronic arms based on customer requirements

- Transfer systems for forging

- Integrated or press-independent dies lubrication and cooling systems

- Forged pieces cooling systems

Mecolpress is responsible for the direction and coordination of the works.

As CEO, we are able to ensure continuity, support, and timely advice.

What enables Mecolpress to be at the forefront of Co-engineering activities designed to produce hot forging machines?

- the high number of projects completed,

- our experience in hot forging started in 1969,

- our constant presence on international markets.

All this has allowed us to gain considerable experience in the industry and to offer reliable service.

Getting a perfect forging solution becomes possible with Mecolpress:

- We reach an objectives set with the customer,

- We continually seek innovative solutions to achieve the perfect shape forming technology,

- Our R & D team is constantly committed to meeting the different needs of the customer.

These have always been the cornerstones of our mission.

The presence of Mecolpress at EMO2017

Mecolpress is constantly participating in EMO at every edition of this event, and this year will bring to the fair its most important innovations that will attract the interest of thousands of visitors.

Especially Mecolpress will show EMO2017 for the first time a newly conceived product, a compact hydraulic press for the forging of complex low-weight pieces that ensures a high level of productivity thanks to the different single or double forging solutions that ensures at each corner.

Mecolpress has developed this innovative product that will enrich the lucky series of ME presses ME100-4L-30, based on the many expectations of its customers and the market in general towards a work center that could present high-precision features along with flexibility, ease of configuration and control.

Other innovations that will be presented at EMO2017 are the GBH5000 stand-alone ovens that allow great precision and modularity, effectively connecting to both new and existing presses, hydraulic, mechanical and screw, of Mecolpress or any other manufacturer.

The new hydraulic press with heating-cutting bars online

Presentation of new hydraulic press ME100 / 4L30 with with very high productivity,

Heated+Cutting Bar on-line

The new compact hydraulic press ME100-4L-30 dedicated to the forging of complex shapes with low weight, with extremely high productivity.

The new machine is an evolution of the well-known and appreciated Mecolpress ME hydraulic machines, installed and working all around the world, from Japan, through Korea and China, up to Germany and Italy.

Features:

- Multiples coring possibility, single or double shape forging (parallel or head-to-head), in vertical, horizontal and at any angle.

- Advanced motion solutions to grant highest speed and the most precise control.

- Designed with focus on fast set up and easy access, maintenance and cleaning.

The brass bars heating+shearing furnace GBH5000 is what the market is since long waiting for:

a bar heating furnace, that at the same time can shear into billets, built as a stand-alone unit.

Advantages:

– independent from the press, as furnaces have always been: can be connected to new or existing presses, hydraulic, mechanic or screw presses, and loading automation, of whatever brand;

– allow the user the best flexibility in the production organisation and company development;

– for all lengths of bars up to 5 meters;

– no problems with small diameters;

– no damaging of the brass grain structure because of long-time high-temperature heating.

We will preview the machine at EMO 2017, follow the event.

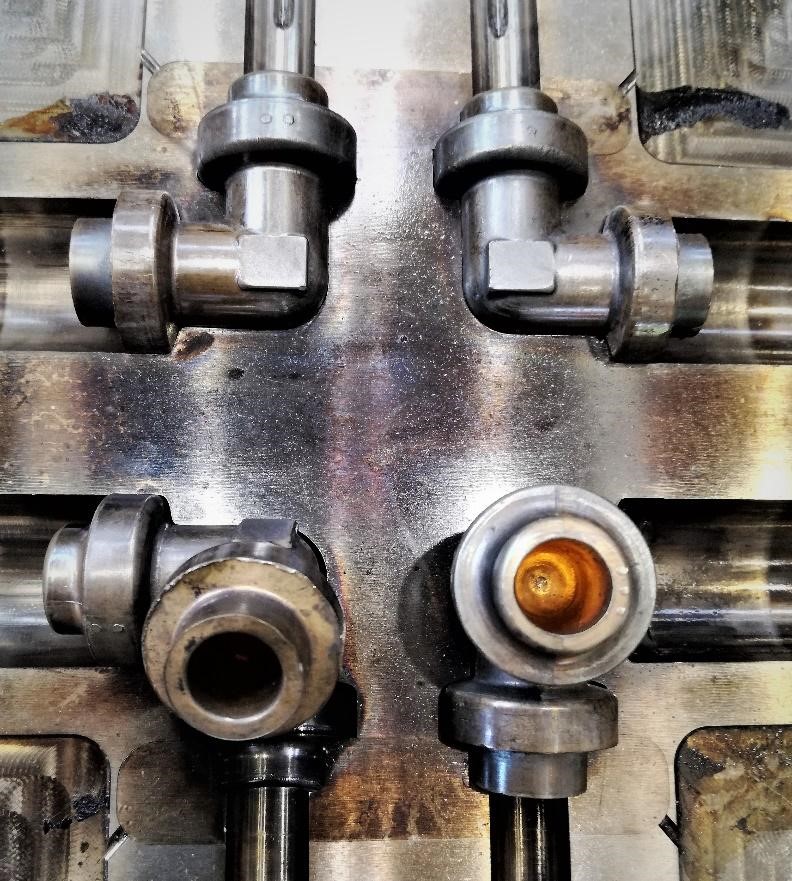

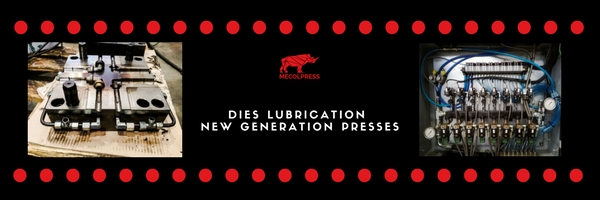

Die Lubrication in the new generation of presses

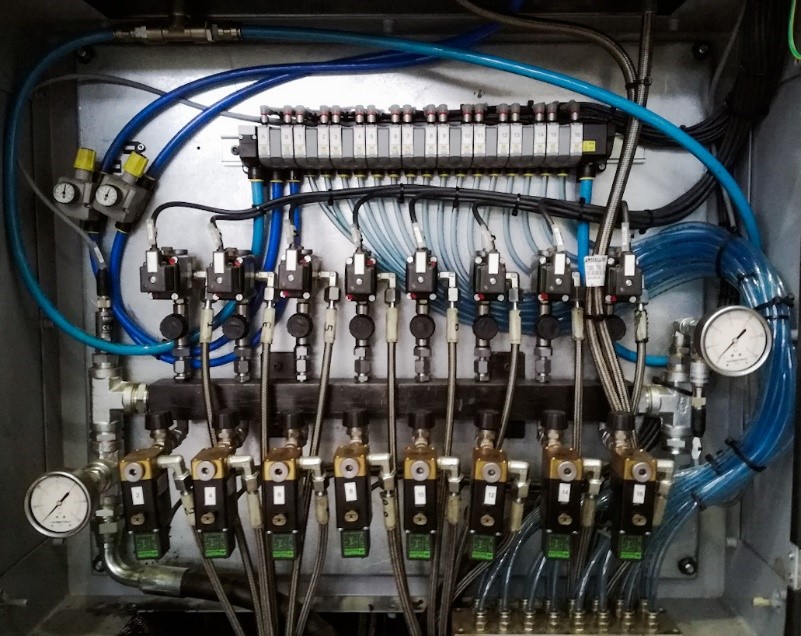

In the most modern presses, like the continuous cycle eccentric SEO-CVE-CS or the hydraulic presses of the ME range:

- The mix oil+graphite is “pulled out” by the compressed air exiting the spraying point.

The lubrication fluid and the air are flowing in two concentric pipes, from the distribution blocks of the single lines to the application or spraying point.

For each of the points, the control is independent and it is therefore possible to decide for each one, from the operator panel:

- How long to spray air only (for example to reduce the temperature of the die and clean it from small burrs);

- How long then to spray air and the oil+graphite mix;

- How long at the end to blow again air only, to spread the lubricant and avoid thick deposits.

- The lubricant reach the application point through the press structure, the base (subpress) onto which the die is positioned, and through the die itself, all of them foreseen with channels and holes to reach the right points without losses and without spraying where it is not needed.

- Having the lubricant flowing through the machine and the die allow high time saving, because there is no more the need to reposition the and re-bend the singles pipes.

A modern and well thought press must in any case always allow to work with the pipes (Read previous article), that are still useful in case of work with third parties dies, or small batch testing with older dies.

It is even possible to modify existing dies, at the purpose to improve the performances and the precision of the lubrication, and adapt these for less modern machines to have internal lubrication channels.

Furthermore, from the operator panel, it will be possible for each lubrication point, to select if it should work as:

Upper die lubrication point;

Lower die lubrication point;

Punches lubrication point.

Each one of these settings offer specific pre-programmed activation conditions, each single point with its working time for air blowing, oil spraying…

Moreover, in our hydraulic presses ME the lubrication fluid is kept mixed and if necessary heated up in the power unit tank.

It is also important to know that the distribution line is built as a ring.

What does it mean? That the lubricant is always moving in the pipes, and it is therefore excluded every possible problem like lines clogging or lubricant cooling down too much, because the fluid is not staying in the pipes waiting for a valve to open, but continuously run around.

Moreover, there are control manometers at the beginning and at the end of the line, to keep the pressure at a constant level independently from how many spraying points are activated simultaneously.

ADVANTAGES OF THE LUBRICATION SYSTEM:

- Less waste of lubricant materials;

- Tool set-up time extremely reduced;

- Zeroing of the possibility of wrong or imprecise position;

- The lubricant is always moving, it is not staying in the pipes waiting for a valve to open: it is therefore excluded every possibility of clogging of the line or cooling down too much of the fluid;

- The pressure in the circuit is kept constant thank to the control manometers.

All of this is thought to grant to your forging process the “right lubrication”.

Industry 4.0

Hot forging becomes 4.0.

Our machines meet the requirements of industry 4.0.

The ME series hot forging hydraulic presses allow to control the speed, the sequence, the stroke and the force of each punch, allowing to print without any burr even some of the most complicated shapes. The production phases are programmed and monitored to get the best shape.

WHAT WE PROPOSE WITH OUR INDUSTRY 4.0 MACHINES?

- We program what the press must do;

- We program tolerance limits around a test cycle;

- We can control what the machine has actually done;

- The system verifies that the process is stable and identifies irregular anomalies or tendencies of deviation;

- We supervise and record parameters for at least 10,000 cycles;

- We provide a graphical representation of the process;

- All information can be sent to an external PC for further evaluation, registration and quality assurance purposes;

- The machine can send personalized messages to the supervisor, via email, to have full control over the performance of the equipment.

RESULT:

- To get precise analyzes and to make correct decisions;

- Have an automatic selection between compliant printed parts and irregular parts.

By ordering one of our machines you will be able to take advantage of the 250% hyper-depreciation. Contact us for further information