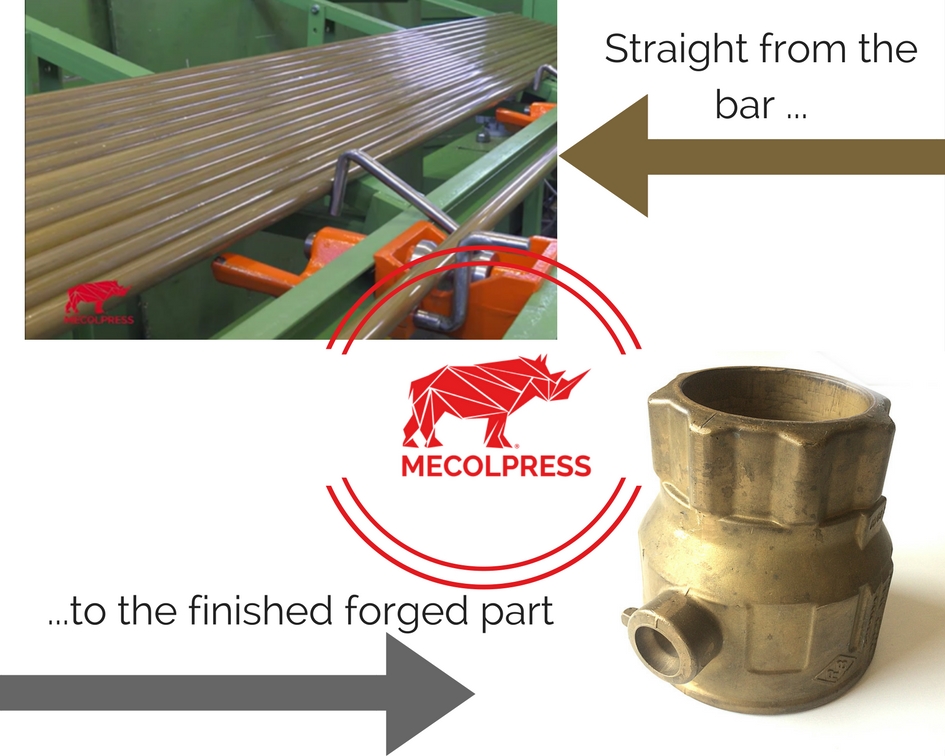

Complete Mecolpress Line for hot forging of metals

Complete line for hot forging of metals

Mecolpress has the abilities and the experience to develop complete forging lines.

We have designed and composed various forging lines, taking care of the whole project:

From the initial choice of the machines and related interconnections, to the installation and commissioning, taking full responsibility of the service and of the after sales warranty of the whole line.

Mecolpress therefore, in addition to in-house designing and manufacturing of the hot forging presses, is able to provide to the customer a full turn-key plant, from the raw material bars to the forged piece (including of course the eventual trimming, sandblasting…).

The productive core of the line is clearly one of our presses, being a mechanical or an hydraulic one.

In the video shown as example here below, you can see a line with a mechanical press of the SEO range.

Forging line with mechanical press SEO

Forging line with hydraulic press ME-G

The ME-G hydraulic presses are particularly suitable to be installed in a complete forging line.

Are machines specifically designed to be used in the hot forging of brass, but have already proved to be extremely flexible and therefore suitable for other materials as well, like aluminium.

With this kind of presses, Mecolpress has introduced in the year 2010 a fully new production method for the hot forging processes.

This technic, called “inverse extrusion”, allow to forge parts even with the most complicated geometries, where the deformation of the material is obtained by means of a pre-determined and controlled flow of material.

This is generated by a programmable advancing of the punches into the die, after that the pre-heated billett has put deposited in the die and this has been fully closed.

The ME-G hydraulic press can be connected and interfaced with:

- Bars sawing / shearing machines,

- Traditional gas or electric induction heating furnaces,

- Furnaces designed for the shearing of the hot bar,

- Automation arms or external robots and of third parties automations for the loading and unloading of the press,

- Flash trimming presses, sand blasting machines…

The interfacing possibility is very useful for example when, in case of an alarm from the furnace side, the press has to be put in a stand-by status and has to record the reason for the production interruption.

In turn, the ME-G can send to the furnace the information “start / stop billet feeding” and can exchange signal of operating status with other components of the forging line, as well as the production parameters with the customers’ own factory supervisor systems.

Hot forging presses: Mecolpress technology

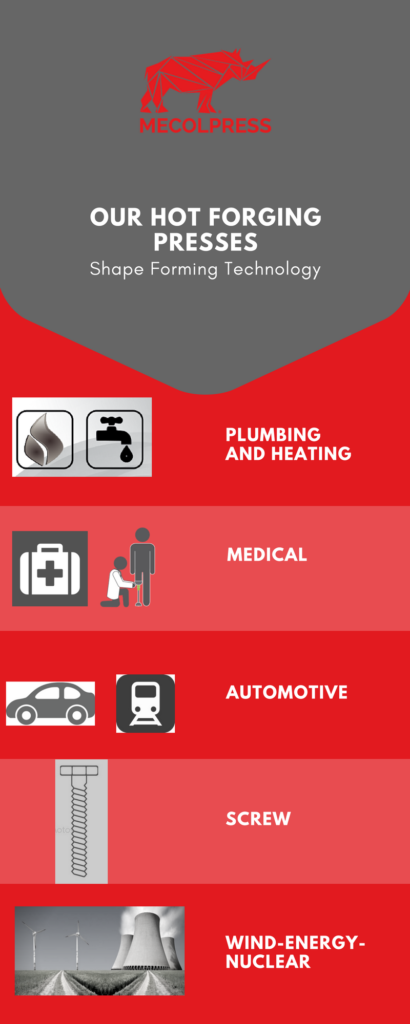

Application sectors of the hot forging

Mecolpress offers a wide range of hot forging presses, able to satisfy the necessities of the individual customers and that allow to forge parts for different industrial sectors. Our presses can be used for the production of:

- Thermohydraulic pieces;

- Mechanical parts in aluminum, copper and brass, used in the railway and automotive sector;

- Clothing parts such as buckles and zippers;

- Stainless, titanium and steel screws for applications in any sectors, from the aeronautics to the railway.

The bio-medical one represents a very particular sector, indeed, with our presses it is possible to forge parts for titanium prothesis. The pieces produced by Mecolpress machines address also to the sector of the production and distribution of high-pressure gas, for the medical, automotive and industrial sector.

Not only mechanical presses, here the Mecolpress proposals

A functional commitment that all these sectors have in common undoubtedly is the precision during the material forging, but also from a design point of view Mecolpress reaches through the research for the perfect shapes a remarkable significance. This is exactly why we propose different typologies of presses, including hydraulic presses, mechanical presses, clutch and electrical servomotor screw press, knuckle joint press and trimming machine, that are able to hot forge several materials, including brass, steel, aluminum, titanium and copper.

The support of our Research & Development department

Our range of presses, so differentiated, is due to the work of our Research and Development department, a team that has revealed itself as very precious, not only for Mecolpress Company but also for our customers, because it allows them to achieve several goals. First of all, our staff helps the forger to identify the systems to optimize the production through hot forging of parts in such a way that the further machining will not be needed. Moreover, our specialists can evaluate what could be the productive implications in the usage of different metals alloys and help to identify them. The Research & Development department offers support also for adapting the complete hot forging line composition according to the customer’s needs, to his industrial sector and to the habits of the specific Country.

So, our company is at disposal of the customers in such a way to define with them the hot forging processes, in order to achieve the best result in the production also of high tech parts.

The technology of the shape

The importance of the shape in the industrial applications

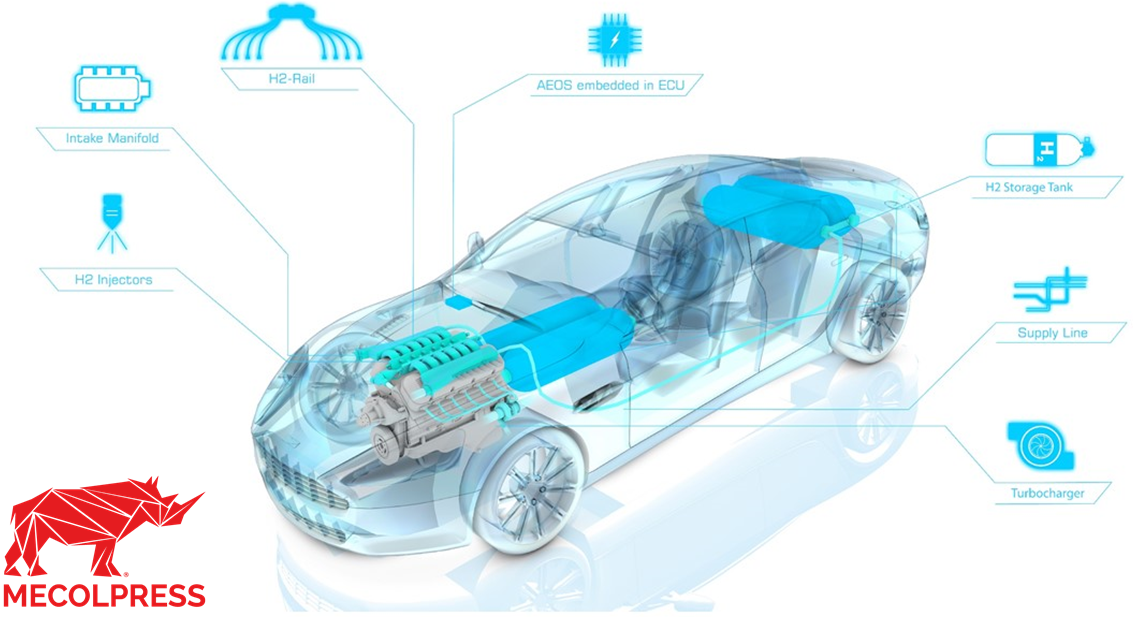

The hydraulic presses manufactured by Mecolpress are able to produce extremely high precision parts, that fully respect the characteristics of the shape originally thought by the designers. This allows to create products of very high complexity like the hydrogen-powered car, that is based on components with the lowest tolerances and on shapes that match each other with highest precision.

Auto ad idrogeno secondo l’interpretazione di Aston Martin (www.astonmartin.com/media)

The hot forging of materials allows, more than any other technology, to obtain perfect shapes and with high resistance, that can be employed in excellence productions.

Mecolpress is a leader in the manufacturing of mechanical and hydraulic presses as well as in the consulting services to use the hot forging technologies for the precision of the shape.

What would be of the technological progress without the shape technologies?

The history of the mankind shows that the research of always better performing and innovative solutions has lead to an accurate care of the details in the production of a perfect shape, in the mechanic industry as well as in the hydraulic, medical technic and building sector ones.

The Shape Forming Technology is also the title of this permanent blog, that Mecolpress issues and updates with the purpose to highlight the need of research and investments for the well-being of the people.

The mechanic of Mecolpress is dedicated to the shape forming technology to provide its customers with the abilities of producing in an always more precise and efficient way.

Follow us on internet facebook LinkedIn