Soft-Impact hydraulic cushion for eccentric mechanical presses

A recent innovation by Mecolpress for eccentric mechanical presses.

Mecolpress proposes to equip the eccentric mechanical presses of an innovative hydraulic cushion, Soft-Impact.

Features:

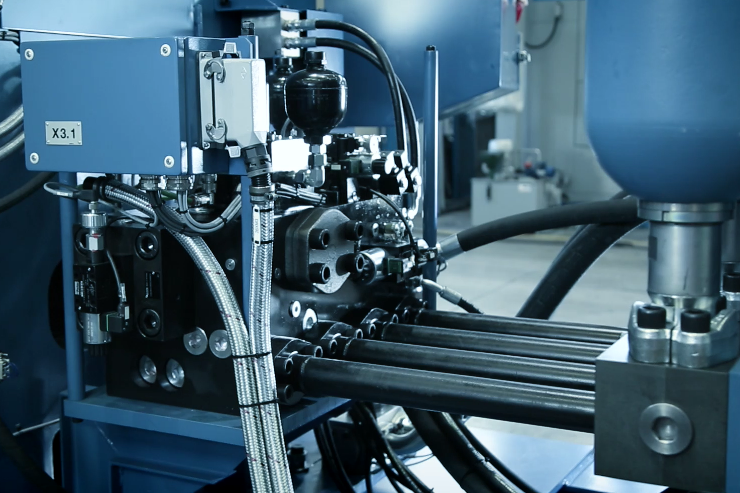

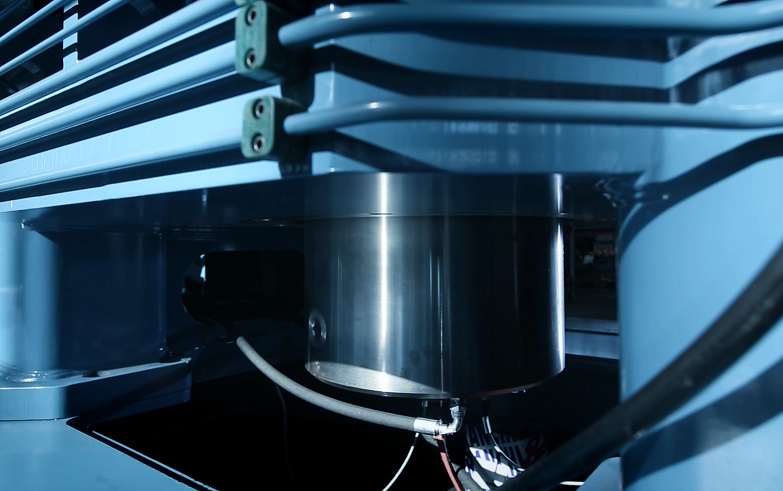

- It is a real hydraulic cylinder with a stroke sensor on the shaft;

- Movements are fully programmable and controlled by means of proportional valves;

- Starts independently the down-stroke and then the punches move forward toward the die center before the upper die hits the lower one;

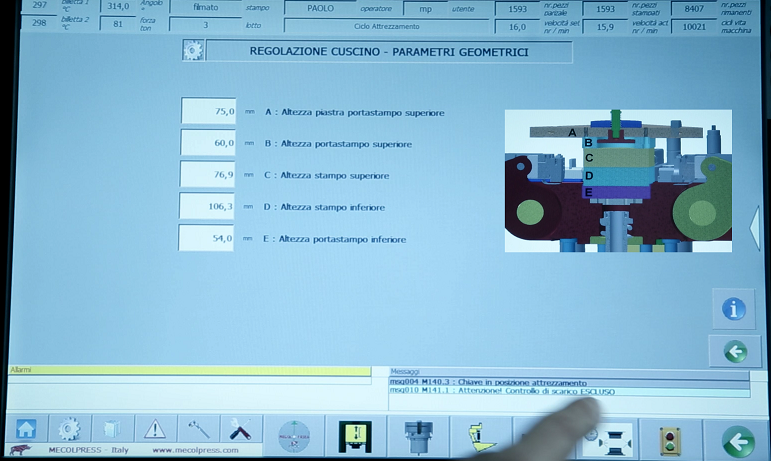

- Strokes adjustment from operator panel by simply inserting the desired dimensions and the data of die and die-holder heights;

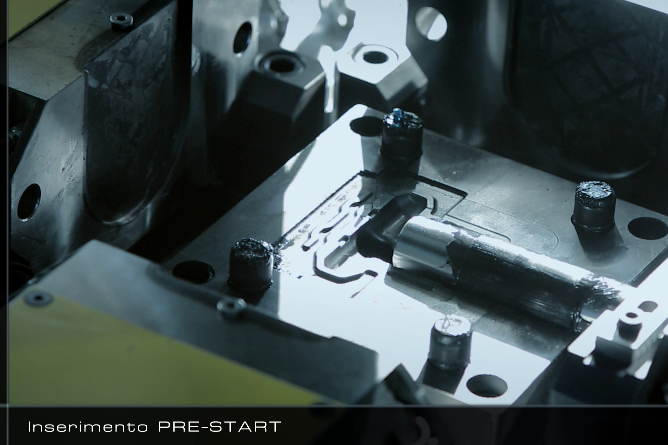

- As alternative, the function “punches pre-start” allows the punches to move close to the billet before the die closes and the forging begins.

- Dedicated hydraulic unit, separated from the machine clutch one.

Thanks to the here above-mentioned features, the soft-impact hydraulic cushion allows the mechanic eccentric presses to achieve important results:

- Extremely simplified mechanical components;

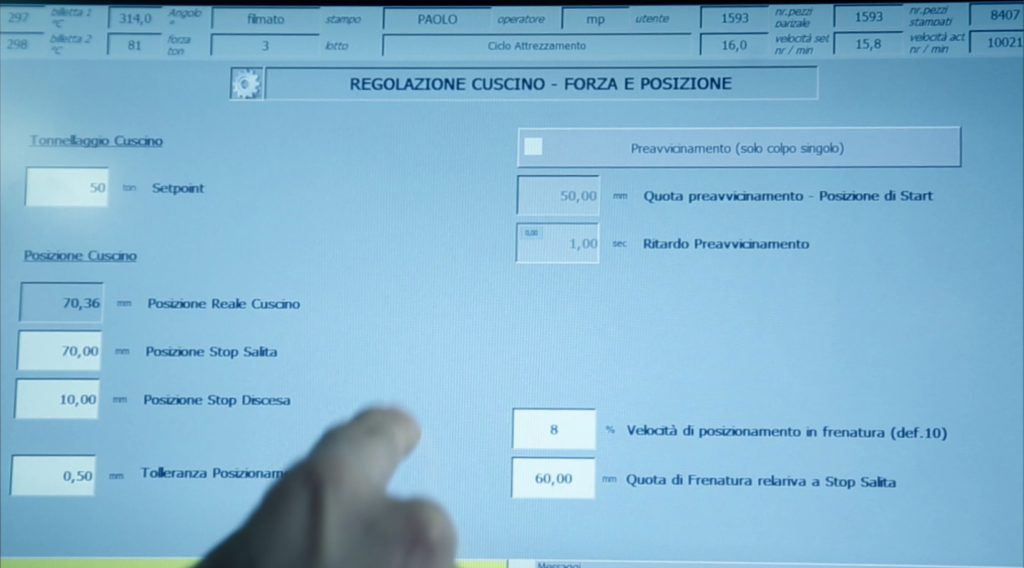

- Precise adjustment from the operator panel of the start, stop and braking quota; all set parameters are saved together with the piece recipe;

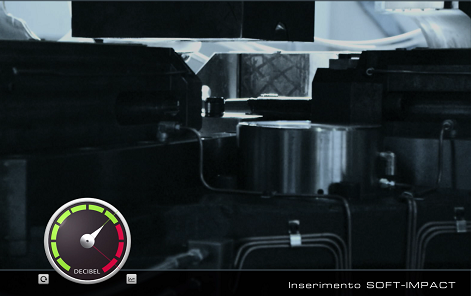

- The upper die does not crash violently against the lower one, because it “reaches” the second one while it is already in the descending phase;

- The control system automatically calculates the speed and the moment to start the cushion;

- When the material deformation begins, the punches are already in an advanced position decided by the operator (it can be saved in the piece recipe); when the die re-opens, the punches then go back beyond the quota of work start;

- Separate blocks modular system.

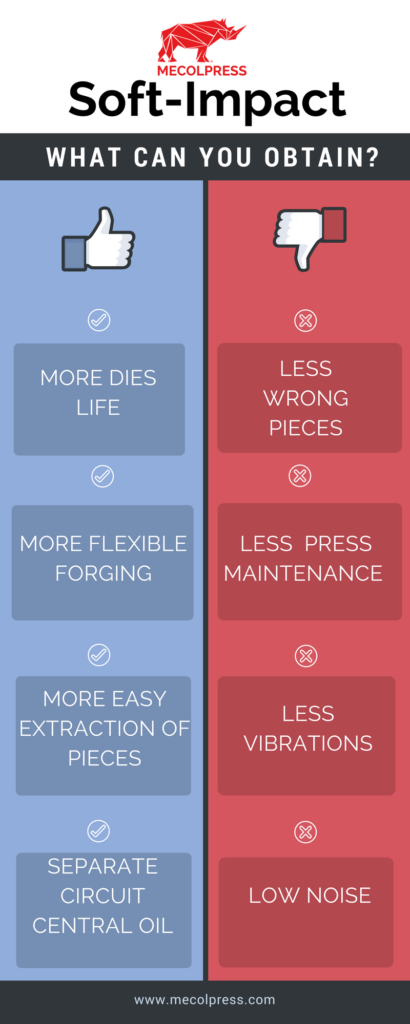

Benefits:

- Less and simpler maintenance;

- Ease of use, machine set-up and perfect repeatability of forging’s cycles;

- Reduction of vibrations, resulting in general benefits for the press and for the working environment;

- Reduction of noise;

- Increased working life of dies and pins;

- No complicated calculations or measures for the operator;

- Possibility of reduction of forging defects due to material that goes out along the empty punch channels and then is pushed inside by punches starting their stroke too distant;

- Ease ejection of pieces (having an extra back stroke) without penalizing the cycle time;

- The oil in the cushion control unit has its own independent circuit and does not mix with the clutch oil, usually dirtier.