Remote forging test

Case study: remote forging test for the acceptance of an entire line

A few weeks ago we carried out a forging test completely on-line.

Generally, it’s the customer who comes to Mecolpress site and follows all the agreed forging tests, the complete development of the necessary activities and the forging phases of the agreed parts.

For the customer this means in any case to travel, physically being absent for some days from the office and personal business, incurring more or less important costs … in conclusion facing challenges weighed down by the situation that has developed because of Covid-19.

In order to meet the need of our customer we have ensured that the forging test for the acceptance of the entire line, that has as cornerstone our ME350 hydraulic press, was carried out totally on-line.

Therefore, we proceeded this way:

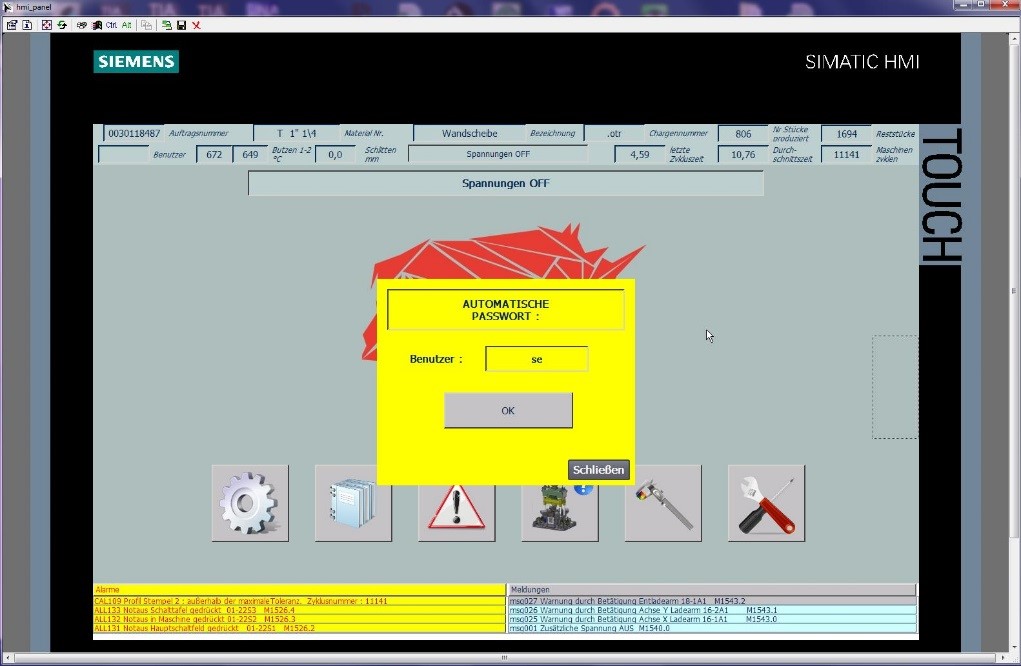

- The customer installs a software indicated by Mecolpress for a safe and certificated VPN connection.

- In this way a connection between customer internet and the press located in Mecolpress is established.

- Now the customer can access directly the machine operator panel.

4. We installed 2 video cameras, reachable by means of ip-adress, running for the whole production duration. The customer can follow the video live from any PCs.

5. Always only inside the established VPN it is possible to access through browser to the two cameras that are always on during the entire forging phase.

6. A technical support representative in Mecolpress is always and in any case available by telephone.

7. All the procedures regarding the setup phase and in particular the die changing phase are visible.

8. All the videos and pictures are therefore strictly confidential and visible from a webcam only to the customer that can save videos, if he considers it appropriate, or taking some pictures, everything always with the maximum confidentiality.

Which have been the advantages for our customer?

The advantages resulting from this acceptance-from-remote procedure of an entire hot forging line are easily identifiable:

- Time-saving,

- Costs-saving,

- Possibility that more people can follow the forging test, comfortably in front of a PC.

New procedures for remote tests

These methods of digital implementations are fundamental, but we still believe that in the world of precision mechanics and capital goods, the aspect of customer consultation is crucial and that as a result the personal contact is still necessary to carry out efficient projects according to partnership optics with the customer and to a deep understanding of his necessities.

Anyway, it is important to offer to our customers the alternative of remote forging tests. The customer experience is however total: video connections, real time data extraction, possibility to access to the press panel.

This procedure can bring also to future developments, for example, let’s think about how it can be useful if it would be set up on the contrary: a Mecolpress technician could have all the useful tools for diagnosing a problem on a machine located in Australia and solve it immediately! Without taking the plane, without taking a long journey, without charging important costs to the customers, avoiding long machine stops.