Brass hot forging: from the mechanical technology to the hydraulic one with me series presses

Metals hot forging is a reliable and repeatable process which allows to obtain components with high mechanical properties, minimizing the raw materials consumption.

Over more than 50 years Mecolpress has been at the service of its Customers, providing the best forging technologies that allow to maximize the products quality and the related productivity.

Not always changing means improvement, but to improve you need to change

Mecolpress is committed every day to sharing experiences with its partners to follow a common path with the aim of overcoming the performance limits of existing production processes.

It is not the strongest of the species that survives, nor the most intelligent one, but the most responsive one to changes.

Exclusively from the merge of the complementary activities:

- Development of innovative technologies;

- From consolidated experience in the hot forged parts production, the way for barriers overcoming in the productive processes can be born;

- Increase of production capacity;

- Improvement of product quality;

- Reduction of raw material consumption;

- Reduction of energy consumption;

- Reduction of resources consumption (lubricants, cooling water,…).

The experience shown in this article is related to the brass hot forging

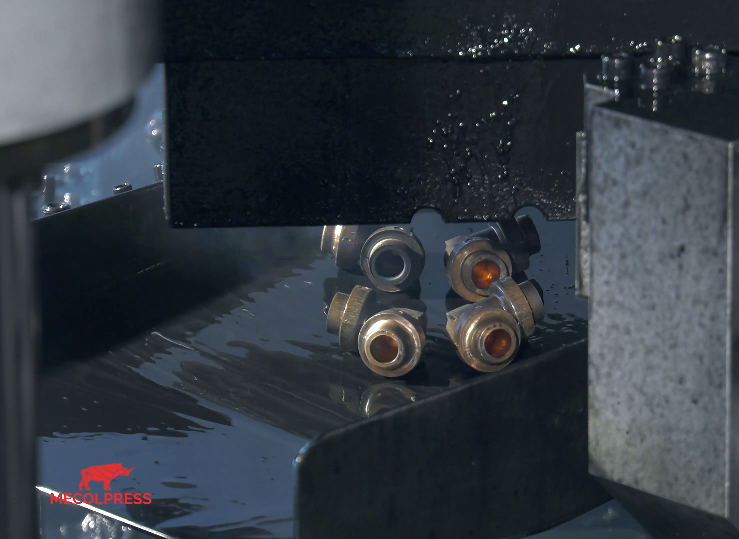

and more precisely to the passage from the mechanical to the hydraulic technology (Mecolpress ME Series). The product subject of the evaluation is the body of a sphere valve with dimension 1” and ½. Even if it may seem a standard and consolidated product, each customer has his own design and specific features.

Mecolpress has collaborated with an Italian industry-leader company to the production of the new die and to its industrialization. After two working days and proactive information sharing, by using our ME hydraulic press, we have reached:

- Production capacity more than doubled;

- Material consumption minimized of about 6.5% thanks to the flashfree forging;

- Improvement of the workability thanks to a more uniform internal conformation;

- Increase of product quality thanks to internal defects removal.

Even if at first sight a forged part may seem perfect, its integrity can be granted only from the internal analysis.

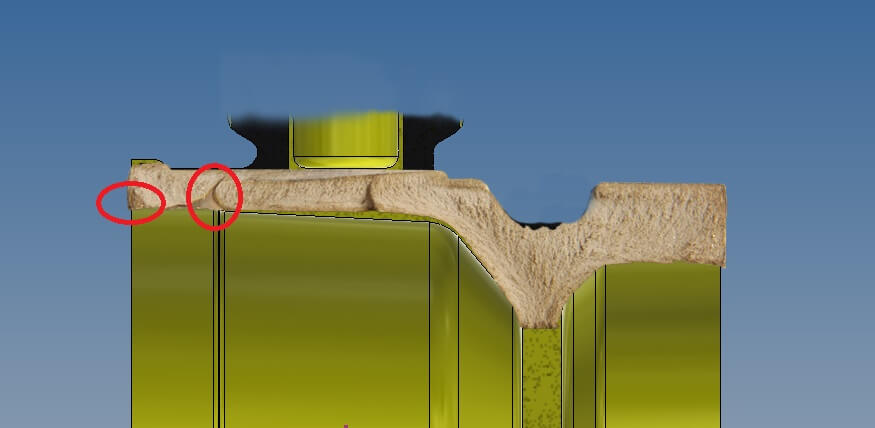

The material flow is unbalanced, the flowing speeds are not uniform, the material tends to detach from the die and to fill some areas before others (picture 1). When the flows meet each other again, they have such temperatures that they cannot be properly welded. The cold welding, indicated by the red circle, can cause problems during the machining phase, if it is included, even partially, in the surplus metal, or if during the assembly phase when the tightening torque of the front nut mechanically stresses the defected side.

Mecolpress hydraulic presses of ME Series, even without any previous simulation numerical analysis, allow to set the correct sequence of part forming according to the material flow dynamics.

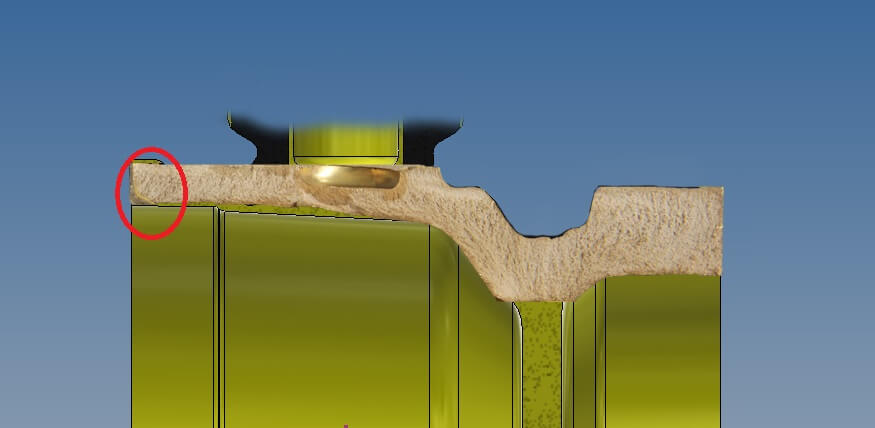

Thanks to this precious pre-forming function a progressive modification of the penetrations of the 3 punches has been applied and this has leaded to the desired result: the repositioning of the defect in a marginal zone (picture 2).

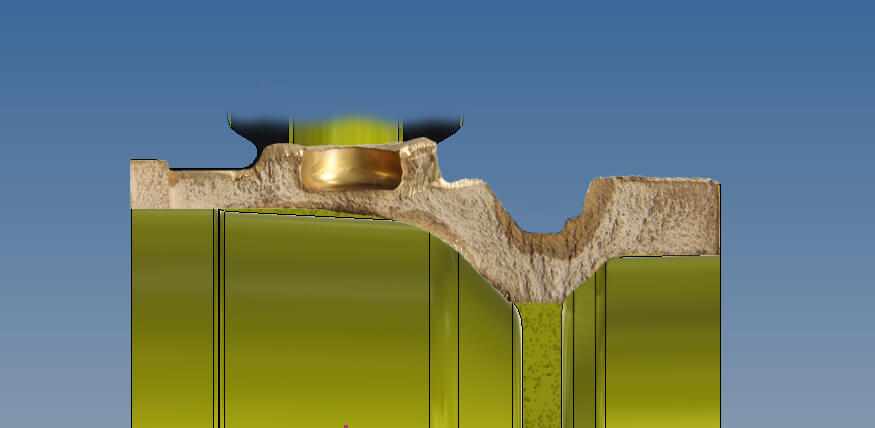

Then simple modifications to punches shape were taken into consideration in order to totally eliminate the cold junction (picture 3).

Two really efficient working days, product industrialization with new dies and more than 5500 good parts in the boxes, ready for the machining tests! A thank goes to our Customer for the precious collaboration, a thank to our team for the availability and speed of action and a thank to our hydraulic ME press that tirelessly, once again, allows to overcome the production limits and to permit a great improvement!

Wait!!! And what about energetic consumptions?!?! We are collecting data… a little patience… in the next article you will be informed about everything!

Mecolpress range of presses

For metals hot forging it is possible to use both mechanical and hydraulic presses. Mecolpress proposes high-tech and of different types machineries in order to satisfy nearly all production needs.

Mecolpress presses are indicated for copper, brass, steel, titanium and aluminum hot forging.

Mechanical presses

Among Mecolpress hot forging mechanical presses there are eccentric mechanical presses that are classified according to the nominal force. SOV model for vertical forging: they require an average energy consumption and are characterized by their high productivity. Instead, the SEO presses are developed for the forging of parts with coring and are divided in:

- SEO: (at single cycle): presses for forging with horizontal coring, high energy, medium Productivity

- SEO- CVE/CS: (at continuous cycle): presses for hot forging with horizontal coring, high energy, high Productivity

- SEO-F: (a ciclo singolo): (at single cycle): presses for forging with vertical coring, high energy and medium productivity

Another type of mechanical press offered by Mecolpress is the screw press.

The screw presses are divided according to the screw diameter and there are three available models:

- TDS: direct control with electrical servomotor. The screw diameter goes from 240 mm to 525 mm.

- Dellavia: friction discs control. The screw diameter goes from 130 mm to 460 mm.

- Osterwalder: friction discs control. The screw diameter goes from 150 mm to 220 mm.

Hydraulic presses

Our hydraulic presses are part of ME series and are characterized by their dies closing force that goes from 100 to 500 Tons.

These are the tonnages we have realized so far, but we can realize tonnages with greater closing force, as well. The horizontal coring punches force goes at present from 30 to 350 tons and also in this case, upon request, it is possible to produce the machine with a greater force than the indicated one.

Presses for parts coining and calibration

Mecolpress offers to its customers that need presses for parts coining and calibration the knuckle joint press of PG series, that are characterized for their low stroke and very high productivity.

These are classified according to their nominal force.

Machineries for parts trimming:

Mecolpress trimming machines are classified according to nominal force, as follows:

- PO:trimming machine with single station, low productivity, generally used for manual loading, H structure. Tons from 10 to 60.

- S: trimming machine with multiple stations, provided with rotary station with hydraulic motor. It is characterized by a medium productivity rate and it is used for manual or by automation loading, H structure. Tons from 10 to 60.

- E: Trimming machine with multiple stations, equipped with rotary table with electrical motor, high-medium productivity, more suitable for loading by automation or robot, C structure. Tonnage from 10 to 60.

Thanks to the variety of offered machineries, our sales department can suggest you the press that best fits for your project according to the type of part to realize and according to the specific conditions in which the customer operates.

Hot forging of the brass: advantages of this material

The brass and its characteristics

The brass is an alloy composed of lead, copper, zinc and other metals, whose percentage can vary. The main component of this alloy is the copper that has a percentage between 55% and 62%. This high content of copper makes the brass a good electricity conductor and a material of easy mechanical machining because it does not wear out the cutting tools quickly as it instead happens for iron or steel.

Other typical features of the brass are:

- Recycling ease: brass is often remelt and reused to produce new parts.

- Resistance to a wide temperature range: during the hot forging process the brass is able to support, without creating particular critical issues, a moderate temperature range, this simplifies considerably the work, allowing a major tolerance in the usage of machineries.

- Lacking oxidation: During the heating phase inside the die, this metal is not subject to considerable oxidation.

- High corrosion resistance: the brass is a nonferrous alloy and therefore it does not get rusty.

Sectors of brass application

Thanks to its colour similiar to gold, the brass is used also for the realization of ornamental elements, home furnishing pieces such as for example handles and finishing for furniture, elements for clothing, including zippers and belt buckles.

Another sector of particular importance is composed by fluid control. This metal is particularly fitting for the production of valves, junction and fittings; since specific brass alloys with unimportant lead content were realized, the so produced pieces are therefore suitable to the contact with drinkable water. These special alloys are defined as Lead-free

In the end, as already underlined, the brass is a good electrical conductor and this characteristic makes him suitable for the realization of the electrical and electromechanical components, including switch parts, connections and terminals.

The hot forging process of the brass

The brass, that thanks to its particular plasticity permits to produce complicated geometrical shapes with simple processing, is hot forged as follows: when the press closes the dies with a single hit on the billet, it turns it into the part to be realized (in contrast to the steel that needs almost always a sequence of many hits). Inside the two halves of the die, that have the shape of the part to be realized, it is set down an enough quantity of metal in order to perfectly fulfill the entire cavity created by the two dies once they are overlapped and closed.

Presses for brass hot forging

For the hot forging of the brass it is possible to use continuous cycle presses or single cycle presses. The continuous cycle press is provided with a ram that moves continuously without stopping. The billets loading and the forged parts unloading is automatically adjusted by the electronic check. Instead, the single cycle press expects, at the dies reopening after a single hit, that the order for a new descent or closure of the dies must be sent by the user or by the PLC.

Mecolpress presses for the hot forging of the brass

For the hot forging of brass parts, Mecolpress proposes numerous mechanical and hydraulic presses with different characteristics according to the production typology that the customer wishes. Lately we have developed an innovative technology on our hydraulic presses for forging four parts with just a single hit that allows an important saving on the productive costs, come to discover how by reading the article!

Hot forging of the brass without flash, a success case

Brass hot forging and its application sectors

The hot forged brass pieces are used in many sectors, including, for example, clothing and constructions industry. The belt buckles, the zippers and door handles are all examples of parts produced with this material and obtained through hot forging presses.

Among the different application sectors, however, the one that sticks out mainly is the fluids control and hose fittings sector.

- Taps and fittings pieces,

- Valves for LPG tank and high-pressure gas,

- Ball valves for water, gas and oil,

- Watermeter bodies,

- Junctions for both the normal and floor heating, these are all brass pieces.

This type of product is currently affected on the market by a very strong competition of the Countries in which the manpower is cheaper and where probably in some cases a brass alloy is used that responds mainly to the local necessity and to the temporary availability, rather than to satisfy the international quality standard. To produce this kind of pieces in Europe, saving competitivity on the market represents therefore a challenge for many companies.

Hot forging without flash four brass parts at the same time

Speaking with a customer of ours who has the productive headquarter in Europe and who produces brass pieces, we could experience his real difficulty to remain on the market. From here comes the idea to find a solution that could allow him to increase the productivity and to reduce considerably the wasting material for sparing on the costs.

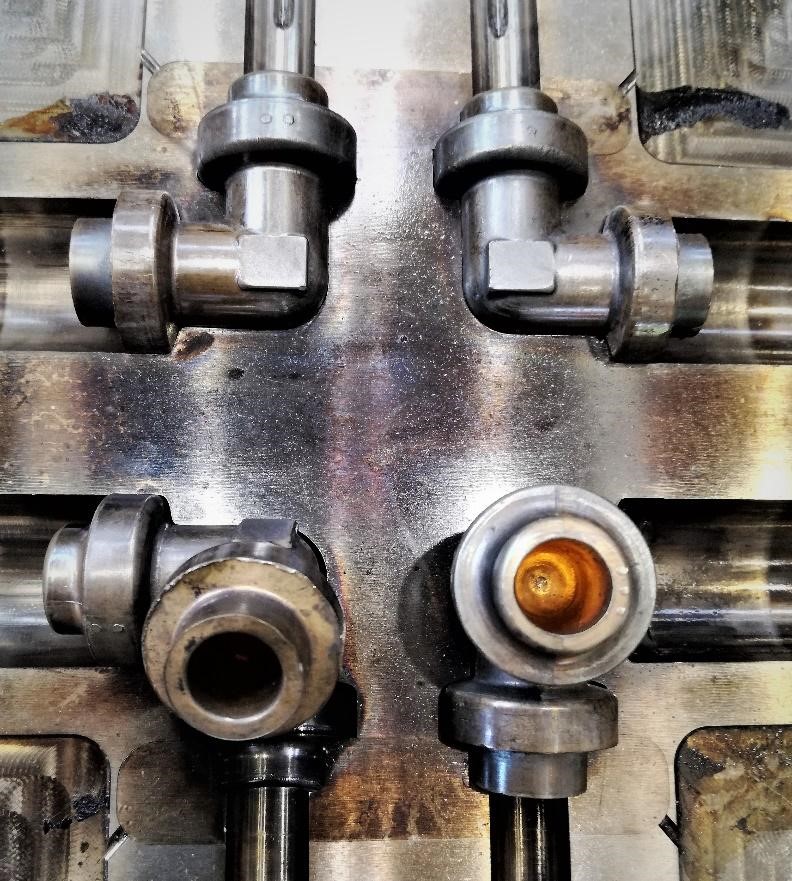

Our staff in collaboration with the technical office of the customer has identified then two different dies: one for the production of a hose junction connection and another for a curve of 90°. These new dies have been developed to take advantage of the potentiality of our hydraulic presses of ME serie of forging without flash and the result was to forge 4 parts at the same time.

In order to obtain this result, it is necessary to provide one of our standard hydraulic presses, such as the ME250/4G100, with some optional accessories (including also the billets loading system), that are conceptually simple but extremely well-performing.

This system is different due to its strongly innovative characteristic, since at the moment just the Mecolpress presses can provide this result (forging 4 pieces at the same time without flash) that surely brought great advantages also to our customer in terms of marginality on the product cost.

Through this specific press for the brass forging, it is possible to produce 4.500 parts at hour on average without flash.

This case study shows how it is possible to find solutions in the concrete and proactive collaboration with the customer that satisfy in the best way the specific productive necessities of that company and for its own specific interest.