EXHIBITIONS 2023: MECOLPRESS AT FORGE FAIR (OHIO)

Forge Fair 2023

The United States of America is the country with the highest Gross Domestic Product and has always represented the reference point for the world economy. The tradition of the US manufacturing industry is long-standing and its importance is always growing in every sector. PRODUCTLY MADE IN THE USA!!

Mecolpress with its 50 years of experience in hot metal forging is proud to make its know-how available to make American customers and partners more competitive. Mecolpress has started this process since the 70s and hasn’t stopped yet.

We are proud to announce our presence at Forge Fair 2023 which will be held in Cleveland (Ohio) from May 23rd to 25th. Forge Fair, organized by the Forging Industry Association, is the largest and most important event in North America exclusively dedicated to metal stamping and forging. It will be a pleasant opportunity to discuss and connect the main industrial players in the sector with the aim of increasing their knowledge of production processes and improving them as much as possible.

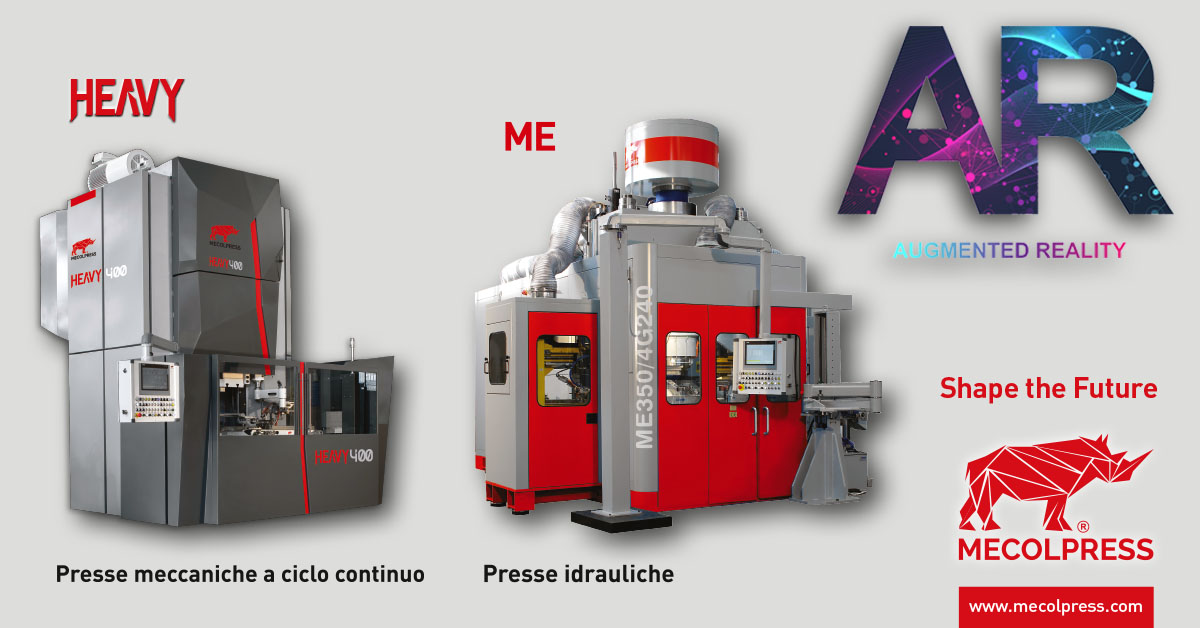

Mecolpress presents the latest innovations related to forging technologies:

- SEO and HEAVY eccentric mechanical presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: forging without burr with significantly reduced energy consumption.

- Direct drive screw presses: to produce parts with complex geometry.

Smart Brass Forging Presentation

You are invited to participate in the SMART BRASS FORGING presentation which will be held on Tuesday 23 May 3.20-3.45 pm (ET), a useful opportunity to learn about the latest proposals regarding:

- the reduction of the consumption of raw materials.

- the reduction of electricity consumption.

- high production capacity and flexibility in product changes;

- continuous quality control of the forging process;

- operational continuity thanks to after-sales assistance.

We will be proud to have your attention and to answer your questions and requests for clarification.

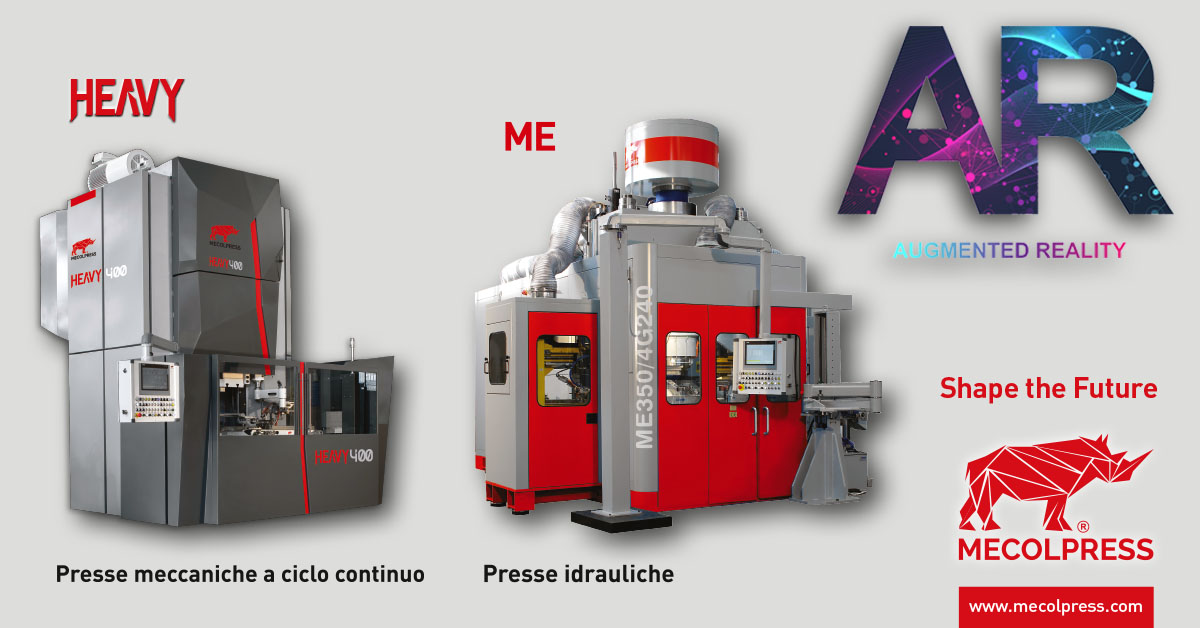

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Mecolpress together with its USA partner Forging Equipment Solution, awaits you at Stand 329 – Exhibit Halls A-B

EXHIBITIONS 2023: MECOLPRESS AT ISH (GERMANY)

ISH 2023

ISH, the world’s leading trade fair for bathroom furnishing, air conditioning and energy saving comes back in presence after the online edition of 2021.

It will be held from 13 to 17 March 2023 in Frankfurt at Messe Frankfurt. This trade fairs covers many sectors.

We look forward to seeing you at our Booth, Hall 9.1, Booth no. A53

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Smart Brass Forging

We report the article below FIA Magazine, the Forging Industry Association, that speacks of us.

Smart Brass Forging

By Danilo Fagnani

MECOLPRESS started their activities in Brescia (Italy) more than 50 years ago, in 1969, providing solutions for the hot brass forging industry. MECOLPRESS then widened its portfolio including hot forging steel, aluminium, titanium, and special alloy applications. MECOLPRESS is now offering the most modern technologies available for mechanical (HEAVY family), hydraulic (ME Family) and screw driven (TDS, FPN family) presses.

The region of Brescia, located East of Milan, is generally considered the cradle of brass production, at least 20% of the total world production is firmly located here. The Brescia region is still able to compete with Chinese brass manufacturers (35% of the brass total world production) even if the production costs are not comparable in terms of manpower, energy and etc… The secret of this success is the know-how of the full brass production chain, industrially started from the 19th century, from melting process passing through forging then achieving the final product completion. MECOLPRESS was born and built in this interesting and dynamic environment, participating and contributing to solve the main challenges of brass producers (Smart Brass Forging).

These challenges are cyclically recurring in the market, and they can be summarized as follows:

- raw materials availability and costs;

- high variability in the market for parts from the peaks of high demand to small lots with frequent parts changeovers;

- difficulties to find the necessary manpower, from highly skilled operators, to maintenance technicians, to standard operations workers;

- availability to grant the best products quality reducing the non- compliant ones;

- reduction of the energy consumption approaching the green economy

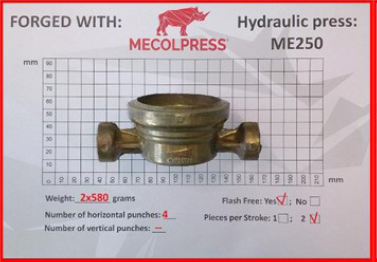

MECOLPRESS is supplying to the market the most powerful hydraulic presses (ME family) offering horizontal\vertical coring performances achieving:

- flash-less forging;

- reduced part material thicknesses;

- deeper and deeper punch coring

These features drive achieving parts with less weight and avoiding any further downstream process as trimming. ME hydraulic presses family (more than 60 units supplied from 2010) has standard sizes:

- 100 to 500t as die closure force

- 30 to 350t of punch coring force

The coring punches have independent movement guiding and optimizing the flow of material inside the die’s cavity. The punches forces, speeds, displacement sequences can be flexibly implemented in the HMI operator panel depending by the products to be forged (Smart Brass Forging). One of the four horizontal punches can be orientable (without losing coring force!) with the variable angle from from 0 to 45° allowing sloping coring for the parts.

The ME family hydraulic presses grant production performances that, depending by the equipment size, can reach up to 30 cycles per minute and they allow to forge multiple parts per stroke, throughout of some thousands of parts per hour is easily achievable. This will allow to complete productions lots is shortest time even if they are relevant in the number of parts to be reached. If the market conditions are changing and the market moves to lower number of parts per lot with frequent shifting between the products, the quick dies changing system will allow to dramatically reduce the down time. The fully automatic tools locking\unlocking and the servo-moved supporting arms allow one operator to accomplish the change in the quickest time (about 15-20min), in the complete safety conditions and without the help of any tools (Smart Brass Forging).

Mecolpress ME Next Generation series hydraulic press hot forging EG coring tool

The MECOLPRESS policy to reserve relevant stock of spare parts for all the presses that have been supplied is a key point to avoid unwanted down time in case of maintenance of the equipment.

Mecolpress ME Next Generation series hydraulic press outstanding parts weight reduction

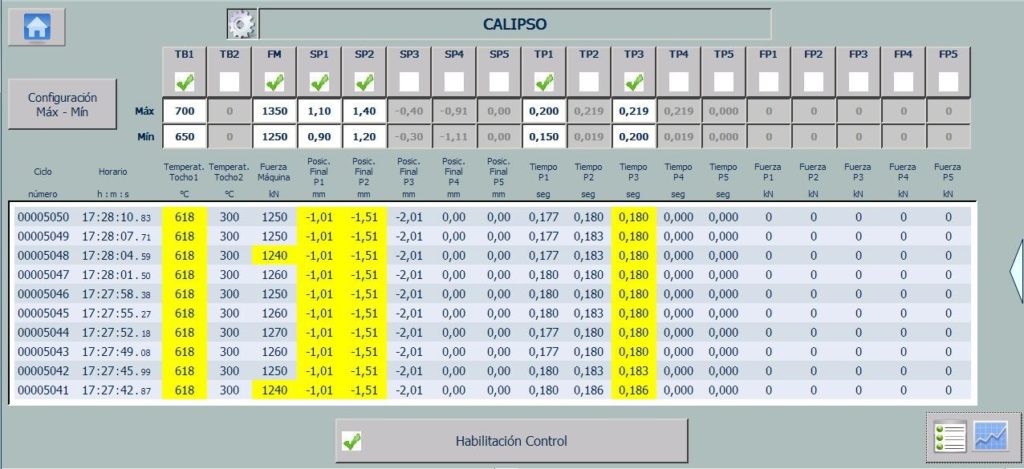

MECOLPRESS is developing all of the control software for the presses: CALIPSO (Smart Brass Forging). This user interface is based on a touch screen model, it is very easy and intuitive, and it has been developed in several different languages; it allows any end user operator to work with continuity on the press and it does not require any particular skills or knowledge. Many functions have been simplified as input parameter requests to reduce the human factor effect in the press working conditions. CALIPSO defines and controls automatically all the ME family presses operations, from raw material loading up to forged parts unloading. The main parameters of each product receipt are saved in the internal memory, and can be easily retrieved for future production and transferred to customer MES\MRP. The press has an Ethernet OPC-UA connection module that grants this function as well the remote teleservice assistance by the MECOLPRESS technicians.

The MECOLPRESS R&D department is able to define the optimized process parameters and/or the best die geometry through FEA software which allows them to analyze both material flow and forging force. This on-demand service is appreciated by customers who are searching for a reliable supplier.

ME hydraulic presses can be paired with all types of furnaces: billets, bars, natural gas, electric induction, keeping in mind that the reliability on the heating temperature, the billet weight tolerance and the material metallurgical microstructure properties are key parameters to grant effective flash-less process success.

High production capacity, flexibility to switch from one product to another and high equipment reliability vanish if the forging process is not under full control. CALIPSO software is leading the game supporting the customers to control, with minimal effort. The forging forces, punches displacement parameters and sequencies, billets temperature, and so on can be monitored in the maximum\ average values or continuously during the working cycle. The desired thresholds can be set in the system to monitor the trends of the parameters and if any mismatch is found, the parts can be diverted automatically to the dedicated collecting box for further checking.

MECOLPRESS is fully committed to be an effective part of the green transition of the industry, reducing the energy consumption, pollution emission, and media consumption. This application shall not decrease or compromise the outstanding powerful performances of the ME family presses. CALIPSO and in-house engineering are the main characters of this target:

- hydraulic auto-adaptive regenerative function circuits;

- ECO mode for working pressure optimization;

- actuators optimized geometry;

- flexible set up of the operating pressure;

- AC frequency converters\variable flow hydraulic pumps;

- CALIPSO software that learns from experience optimizes the working parameters without relevant operator required intervention (Smart Brass Forging)

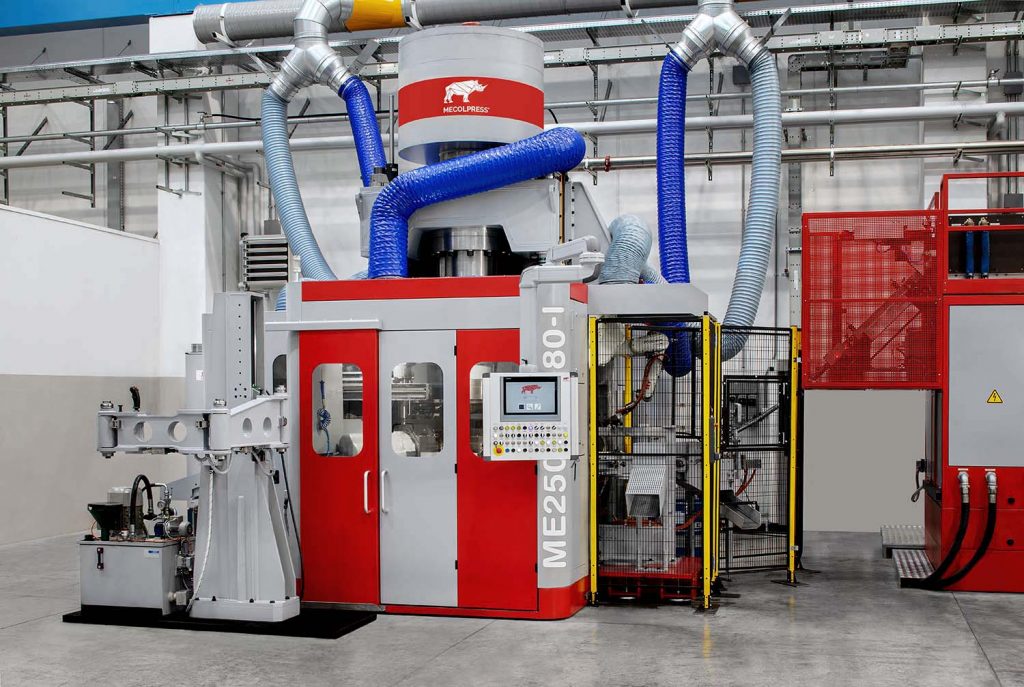

Mecolpress ME Next Generation series hydraulic press main view

These points collaborate to reduce the energetic consumption up to 50% in comparison with standard technology presses.

The dies lubrication system, very important in the flash-less forging, is using innovative pipe to pipe technology supplying alternative air and oil flows just with the needed quantities. All the dies lubrication parameters are set into the control software and up to 30 points can be reached; they can be integrated into the dies or with external nozzles. The proper pumps are installed on the machine bottom to collect all the remaining quantity of oil avoiding any overflow. The press lubrication is selective and only the components active are reached by the media, proper collecting box avoid leaking. No more waste of fluids!

Pressa idraulica Mecolpress ME Next Generation: esempi di particolari stampati a caldo senza bava

Mecolpress ME Next Generation series hydraulic press four parts flash less hot forging examples

The innovative suction hood embedded in the press structure collects the emission very close to the sourcing point, decreasing any possible spread into the environment and granting the best cabinet inside view of the process to the operators.

As all MECOLPRESS products, the ME series fulfills the most severe international safety standards and can be produced in compliance with North American and Canadian ones.

Danilo Fagnani Sales Manager Mecolpress

Danilo Fagnani Sales Manager Mecolpress Spa

Phone: +39-030-2560110

Email: d.fagnani@mecolpress.com

EXHIBITIONS 2022: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2022

Castforge Exhibition from 21 to 23 June in Stuttgart.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 21 to 23 June 2022 Mecolpress will be in Stuttgart at Castforge (Stand 5B57).

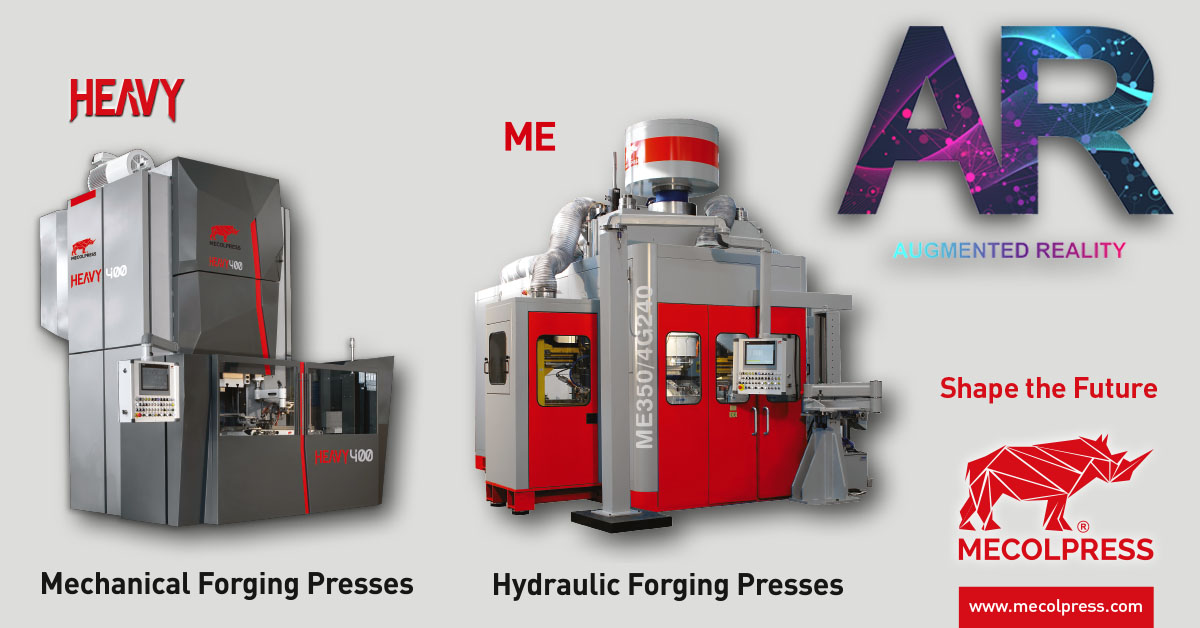

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2022: MECOLPRESS AT BIEMH (Spain)

BIEMH Bilbao 2022

This event will be held at the Bilbao exhibition centre from 13 to 17 June 2022.

Mecolpress will present its latest technological innovations regarding metal forging.

Besides Spanish companies also international ones will be participating in this event, operating in sectors such as: metallurgy, welding, articles and equipment, machine tools, technological solutions, and much more.

You can find us in Pavilion n°5 Stand D34

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

HYDRAULIC PRESS, Mecolpress leap into a new eco-green modality

Main features of the new ME eco-green Hydraulic Press

Mecolpress S.p.a. is glad to introduce the new improved features of ME family hydraulic presses, born from the need to offer to the Customers a more flexible and performing machine in terms of product quality and energetic consumptions.

We are currently proposing the family of ME presses having the die closure force that is in the range from 100 to 500 tons (as standard equipment) and with a minimum side punches force of 30 tons that can achieve up to 350 tons. Each of these last ones has completely independent operation, adjustable speed and set-able movement phases (forward-stop-backward); depending by the type of part to be forged , the hydraulic closure cylinder allows to apply the necessary forging force also before the dies contact.

The new presses can be fed by one anthropomorphic robot for the billets loading and one synchronized unloading arm for the forged products that eliminate the set up difficulties of the traditional past technologies; regarding the fumes suction, after a careful analysis of the actual state of the art, we have implemented and optimized the system making it more functional and effective.

The fume suction hood collects the emission very close to the sourcing point decreasing any possible spread into the press cabin, granting to the operators the best inside view of the process and reducing the oil collection and its possible overflow.

In this regard, the machines of the new series are integrated with the walkable grids that surround the press and prevents the eventual drip on the floor of the working area.

The hydraulic presses can be supplied customized with optional equipment according to the production needs.

For example, one of the punches can be oriented with the coring angle that is different from the classic 90° configuration , allowing in this way the realization of particularly complex shapes, like y-joint or filter body.

Other possible configurations are of new ME eco-green Hydraulic Press are:

- the addition of a fifth vertical punch acting from under the die,

- the loading of one or two billets at the same time up to a maximum of four,

- the addition of a dies-holder arm lightening the machine tooling process,

- the addition of a quick dies changing system with hydraulic locking,

- the addition of an induction dies heating system which the machine is particularly compatible with,

- fire extinguishing system integrable with the machine.

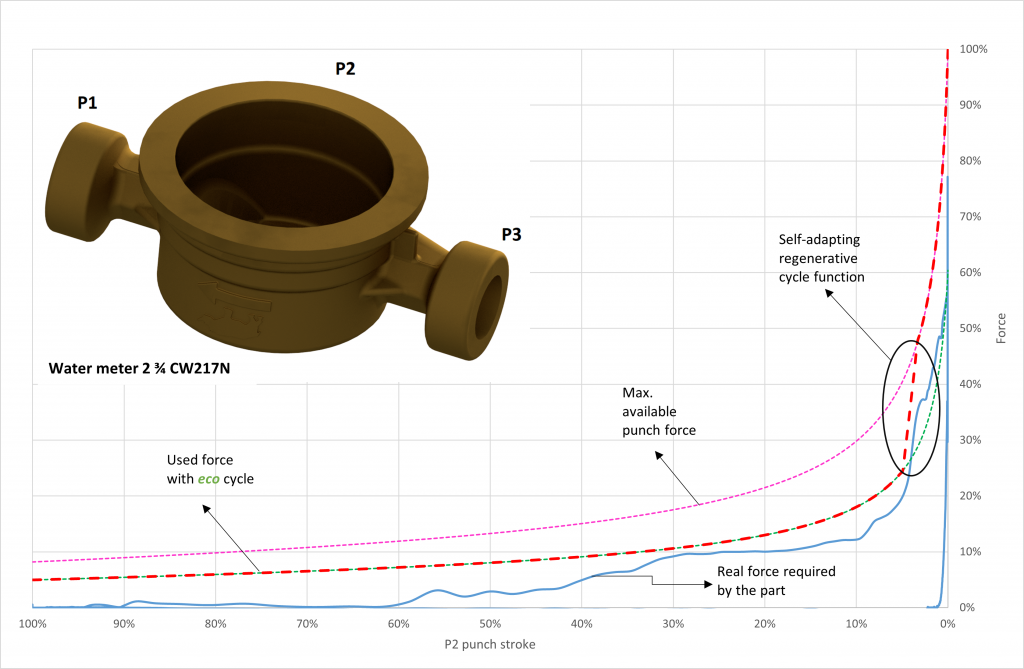

Moreover the main innovation is related to the energy saving achievements if compared to the previous series.

From 2022 all the ME presses can minimize autonomously the energy amount that is needed to produce the desired forged part: the press learns automatically the optimal pressure to be addressed to each forging punch: ECO cycle (settable from the control panel). Furthermore, during the movement of each forging punch, Calipso control software optimizes the time in which it is necessary to switch to the maximum achievable pressure (regenerative self-adapting cycle function): all the press parameters will be consequently harmonized according to this requirement.

This behavior represents the key economic and competitive advantage for the press user that can save up to 50% of the total installed energy without losing or reducing the punches force and can optimize the forging process parameters in order to minimize the energetic consumptions. To do this the operator direct intervention is no longer necessary. The operator is not required to have a long term experience or particular skills : he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

he will simply have to activate the ECO cycle from the control panel, ME press will care of the rest!

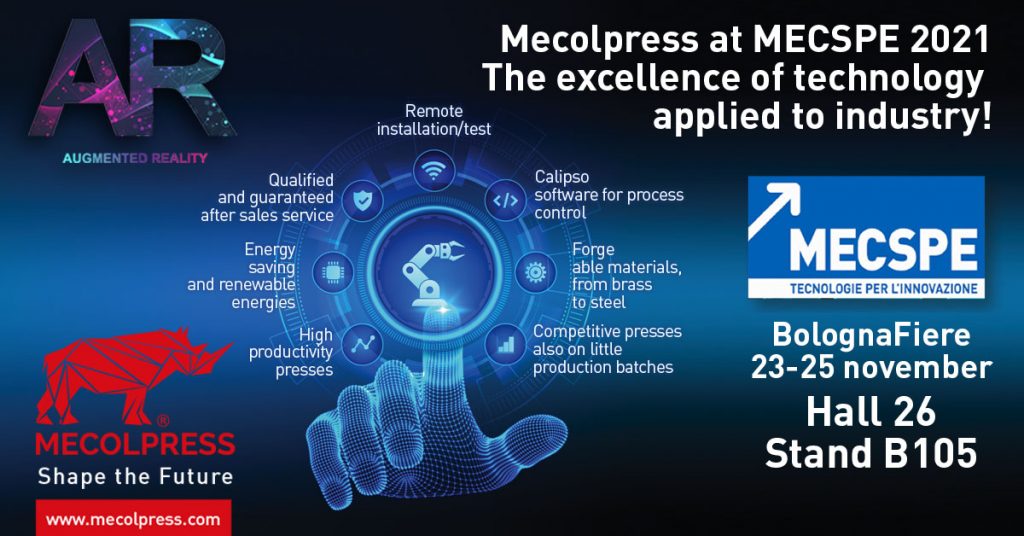

MECOLPRESS AT MECSPE 2021

THE EXCELLENCE OF TECHNOLOGY APPLIED TO INDUSTRY

It has been the most important event dedicated to innovations for the manufacturing industry and it counts 19 editions.

The fair will be held in Bologna from 23 to 25 November.

MECSPE, the main event in Italy on innovative technologies for manufacturing 4.0 industry promoted by Senaf, joins this outlook of restart and business confidence by following its commitment to support this sector and representing itself for 19 editions of over 2,300 exhibitors and trade associations.

This year’s appointment, rescheduled at BolognaFiere, from 23 to 25 November 2021, will have as its main theme “digitalization, training and sustainability”, subjects that visitors will be able to explore through 13 synergistic salons divided by thematic areas, demonstration of talent, commitment and creativity of Italian Companies.

A field, the industrial one, has always been supported by MECSPE which promotes fruitful collaborations between the various players in the supply chain, sharing visions and projects with them, as demonstrated by the historic partnerships with Confartigianato Meccanica and CNA Produzione.

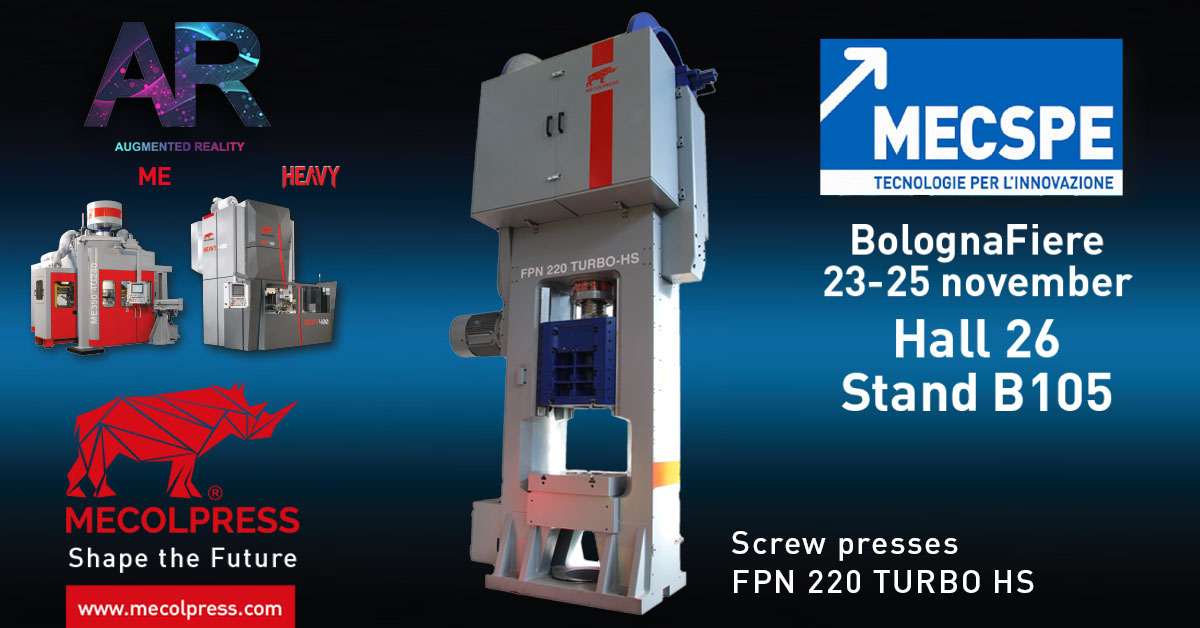

At MECSPE 2021 we will exhibit the FPN 220 Turbo HS screw press.

This is the best evidence of the outstanding performances of the OSTERWALDER screw presses, part of by Mecolpress family from more than 20 years.

These screw presses are particularly suitable for processes where high precision\tight tolerances of forged components are required, for example in the production of gears. They are suitable for hot forging of steel parts, but also of all other materials.

The TURBO version allows to reach higher speed, increasing productivity from 20% to 40%.

Augmented Reality, the press just a click away

In addition to the FPN Turbo screw press, it will be possible to view two other technologies thanks to the Augmented Reality: the ME Hydraulic and the Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

ForEMOst!

ForEMOst!

EMO is the worldwide exhibition of the machine tool, held in Italy and Germany, and that this year will take place in Milan at Fiera Milano Rho from the 4th to the 9th of October.

All the main international players of the manufacturing sector will take part in EMO MILANO 2021; so far there are more than 30 countries represented, covering all the segments that make up the world of the metalworking machines.

Undisputed leader in the trade fairs panorama, EMO represents the whole metalworking world in the best way, showing the best of vision and innovation.

Metal forming and metal cutting machine tools, robots, enabling technologies and automation, solutions for interconnected and digital factories, additive manufacturing will be among the key players of EMO MILANO 2021.

The exhibit is held in the entire Fieramilano Rho Exhibition centre, that can be easily reached with any transport means.

To guarantee visitors and exhibitors the participation in total safety in the exhibition, Fiera Milano Group has developed a Protocol for the safe conduct of trade fairs, in full compliance with the health rules and protocols issued at national level.

MECOLPRESS will participate with a “revolution” of the exhibition concept

Augmented Reality, the press just a click away

This technology allows to overlap multimedia information to the reality framed by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

A very powerful mean in the company communication field, and in this regard, the Augmented Reality has a strong impact on the customer experience, because it transforms the way in which companies interact with their customers.

In the trade fairs the Augmented Reality results to be very useful, both for the exhibitors and for the visitors who will be able to live a visual experience at 360-degrees.

Two will be the presses, chosen from the production range of MECOLPRESS, that will give birth to this innovative space of virtual reality, that will offer the possibility to see and to experience the functionalities of the represented machines.

We are waiting for you Hall 5 – Stand B29

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

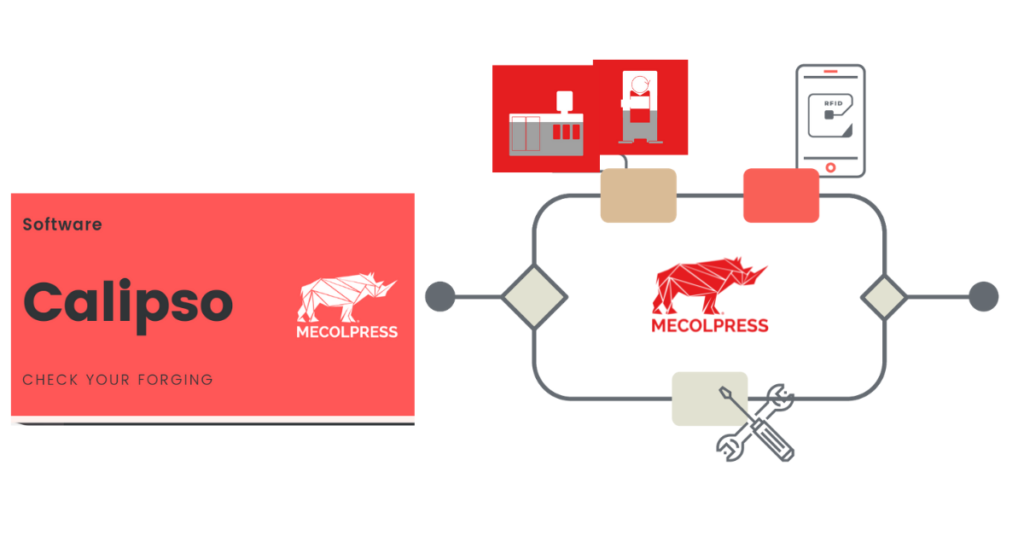

Cloud Presses

This year at EMO2019 we will give practical demonstration of how smart our machines are.

Created by Mecolpress for forging statistic control, Calipso is a software that allows to control the press activities during the entire production cycle, and it is an useful instrument for analyzing the production and for intervening where it is necessary to optimize it.

This intelligent software for the analysis of the production process also includes a sophisticated technology for managing non-conformity

Once all these data have been produced, it will be possible to log them, analyze them and import them into the customer’s management system.

For each machine cycle, a series of parameters are recorded on the operator panel, the last 10 cycles are displayed in tabular form.

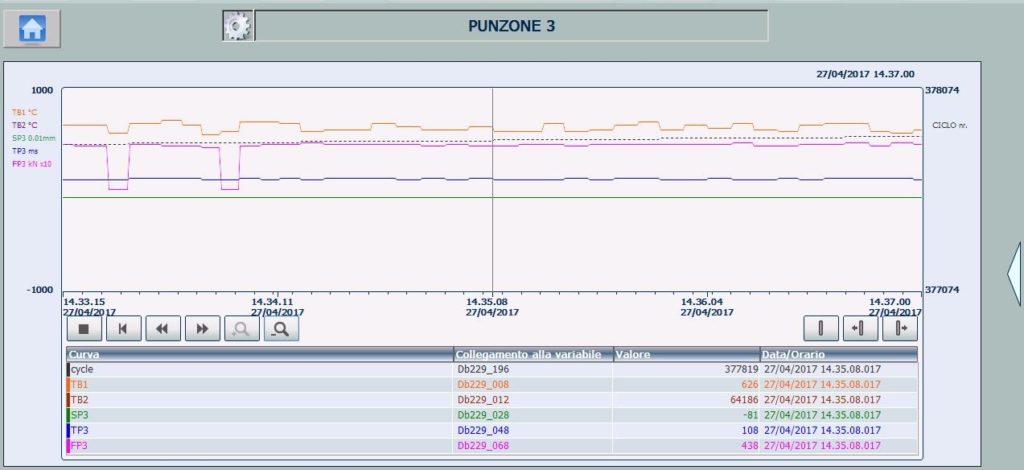

Moreover, the parameters are recorded (the last 10000 cycles) and displayed in the form of trend.

Through the trend it is possible to carry out a cross-check, in order to idedntify the reasons of possible non-conformities.

An example:

At the EMO2019 exhibition in Hanover we present something more:

a practical demonstration, an example of how our machines can communicate with external systems and devices.

Thanks to the collaboration with the Smeup Industrial IoT department, it was possible to integrate our brand new HEAVY 400 mechanical press and ME 100 hydraulics with their IoT Platform.

The production information collected by Calipso can be viewed in real time through dashboards, for an optimal understanding of the data collected by the press.

Dashboards are created using a simple, intuitive and visually striking web tool. Looking at something that is happening at the very moment you are observing is very different from seeing deferred data. In a landscape where speed in making decisions is a determining factor, these tools offer an important contribution.

It is possible to monitor all this, in addition to the local one, also in the cloud: a very interesting aspect as it is possible, through a simple browser, to visualize the result through any instrument connected to the network, from the smartphone to the tablet to the PC, you can always take a look at the data collected, all in real time!

Monitoring the activity of the press, having the information that we are always interested in, getting important alerts or messages useful for example for predictive maintenance, is an interesting plus even for the forging sector that now more than ever becomes intelligent and in step with market demands!