Cloud Presses

This year at EMO2019 we will give practical demonstration of how smart our machines are.

Created by Mecolpress for forging statistic control, Calipso is a software that allows to control the press activities during the entire production cycle, and it is an useful instrument for analyzing the production and for intervening where it is necessary to optimize it.

This intelligent software for the analysis of the production process also includes a sophisticated technology for managing non-conformity

Once all these data have been produced, it will be possible to log them, analyze them and import them into the customer’s management system.

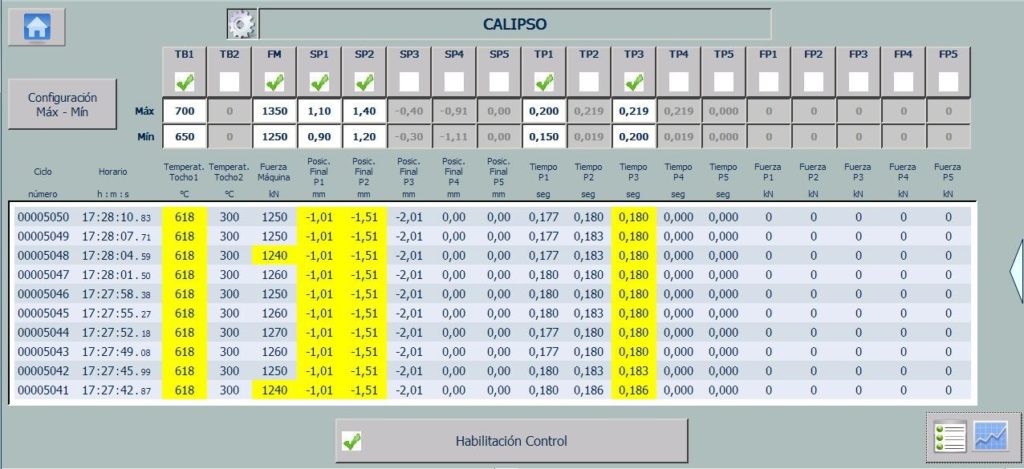

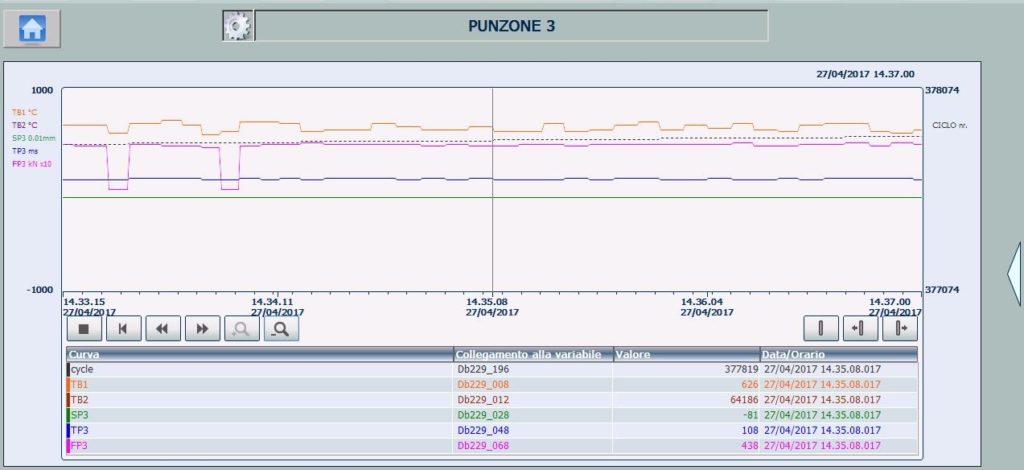

For each machine cycle, a series of parameters are recorded on the operator panel, the last 10 cycles are displayed in tabular form.

Moreover, the parameters are recorded (the last 10000 cycles) and displayed in the form of trend.

Through the trend it is possible to carry out a cross-check, in order to idedntify the reasons of possible non-conformities.

An example:

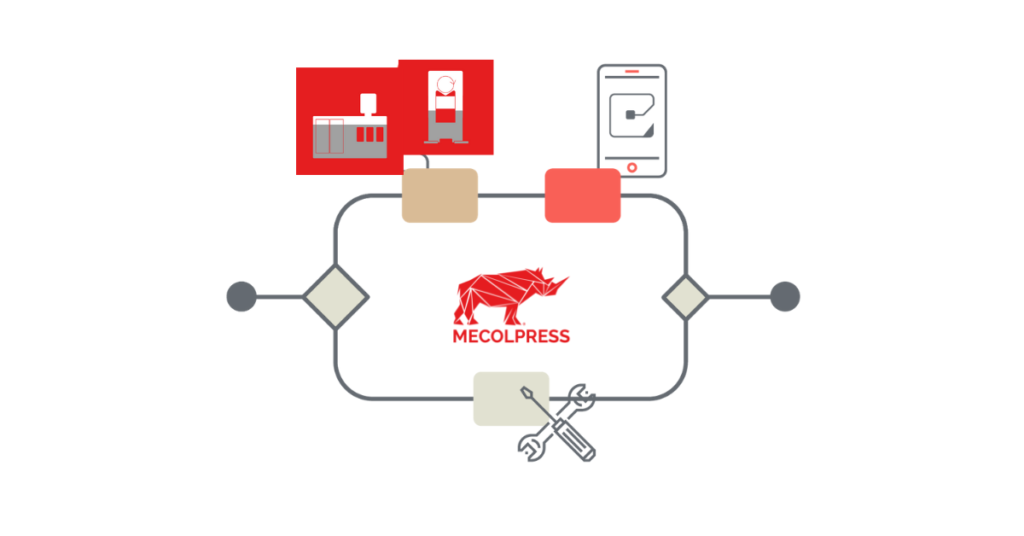

At the EMO2019 exhibition in Hanover we present something more:

a practical demonstration, an example of how our machines can communicate with external systems and devices.

Thanks to the collaboration with the Smeup Industrial IoT department, it was possible to integrate our brand new HEAVY 400 mechanical press and ME 100 hydraulics with their IoT Platform.

The production information collected by Calipso can be viewed in real time through dashboards, for an optimal understanding of the data collected by the press.

Dashboards are created using a simple, intuitive and visually striking web tool. Looking at something that is happening at the very moment you are observing is very different from seeing deferred data. In a landscape where speed in making decisions is a determining factor, these tools offer an important contribution.

It is possible to monitor all this, in addition to the local one, also in the cloud: a very interesting aspect as it is possible, through a simple browser, to visualize the result through any instrument connected to the network, from the smartphone to the tablet to the PC, you can always take a look at the data collected, all in real time!

Monitoring the activity of the press, having the information that we are always interested in, getting important alerts or messages useful for example for predictive maintenance, is an interesting plus even for the forging sector that now more than ever becomes intelligent and in step with market demands!