Why to choose Mecolpress presses?

Mecolpress makes available to its customers quality presses and all its technologic know how. For those who need high performing machineries for hot forging we are a reliable and with a solid experience partner in this field, gained in many years of activity.

Whether it is an entire forging line or a single machinery, Mecolpress can suggest the most performing solution for production and offer a technical support able to face every need.

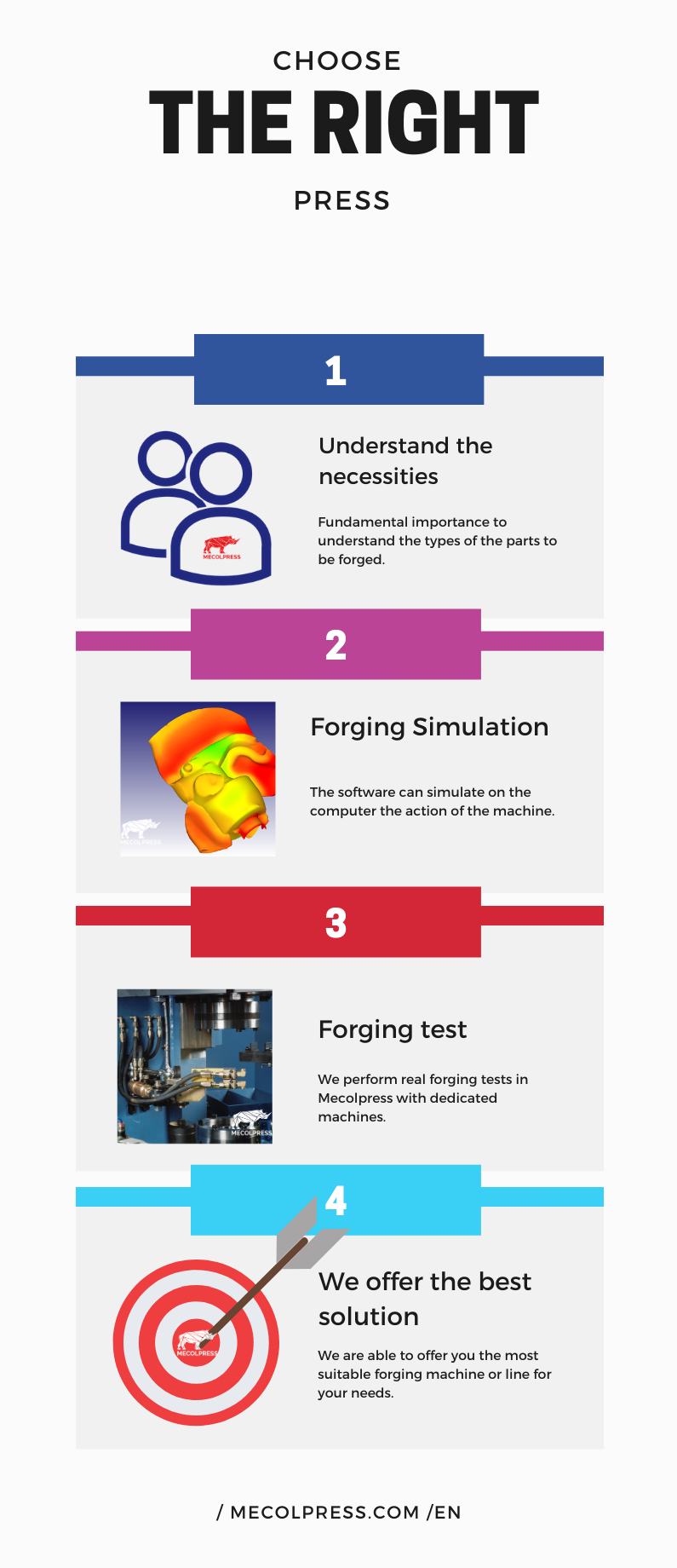

A first meeting to understand the necessities

When a new potential customer contacts us expressing its need to buy a press, our sales department organizes immediately a first meeting either at customer’s or at our premises in order to show the different machines and their functioning.

During this phase, to us it is of fundamental importance to understand the types of the parts to be forged and which could be the eventual criticalities connected to the single parts in order to be able to propose the most suitable press. In many cases our offers are based directly on the drawings of the parts to be forged that are analyzed by our technical office in great details.

In order to understand which is the best press, our technical office takes advantage of a software that can simulate on the computer the action of the machine. In this way we provide a valid tool for the identification of the machinery that meets the productive needs.

Some customers in addition to the single press require the entire hot forging line and, in this case as well, we can provide all the necessary machineries, and to optimize the production.

Forging tests at Mecolpress

Once the most fitting press for the customer has been identified, even if this is hydraulic or mechanical, we carry out forging tests at our premises. So, the customer can be sure in advance of the final result before starting the production at his premises.

In order to carry out the test, the dies for the realization of the wished parts are mounted on the machine. In case the customer does not have the die, there is the possibility to commission it directly to Mecolpress. Indeed, our company offers a complete service to support the customer during all the productive steps and can also offer this component.

During the many years of activity we have gained high technical skills and we have confronted with different situations. The gained experience has turned us into a partner that can understand the forgers needs, able to propose mechanical or hydraulic press for a specific production type.

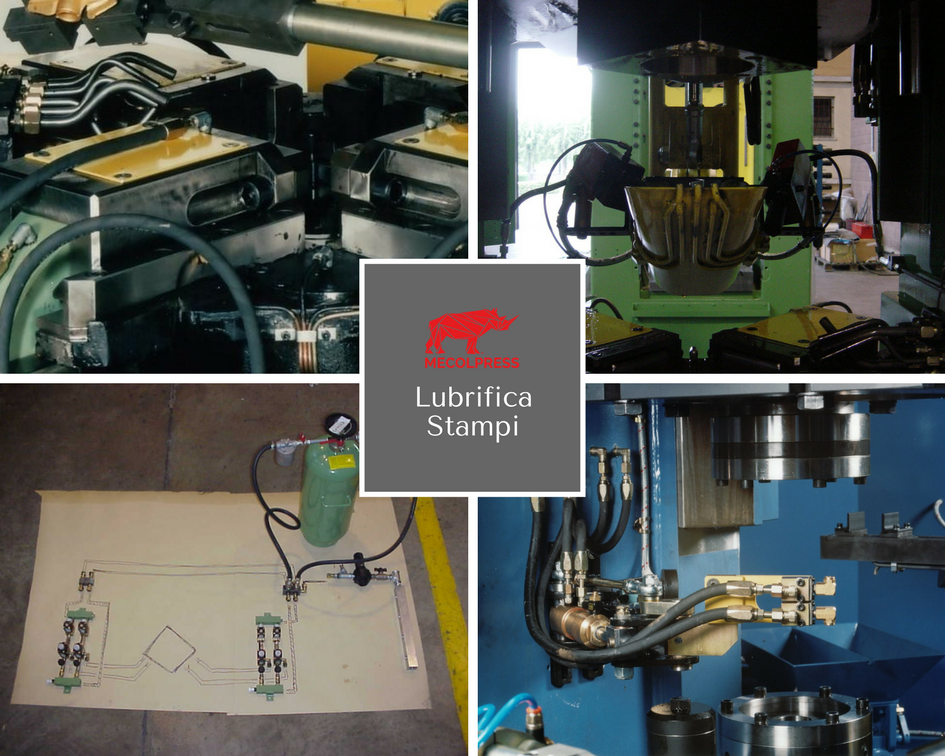

Dies Lubrication

For sure, among the secrets of an expert, to get forged parts at high productivity and without defects, the ability to manage the dies lubrication is one of the most important.

Actually, it is necessary to know how to have a “right lubrication” of the dies.

Clearly, “right lubrication” does not mean “a lot”, but on the contrary it means:

- Well distributed on every point of the die;

- Specifically differentiated between lower die figure, upper die figure, punches heads and their sliding channels…

Punches with spiral grooves to ease the lubrication distribution around the surface

“Right” means first of all to choose the most suitable materials, for the metal that we will forge, and dose or, if required, mix them in the best ratio to obtain the two basic effects of this operation:

- To allow the easy sliding of the punches on the die and of the billet material in the die figures;

- Reduce the temperature of the die components, to increase their working life duration.

The dies lubrication mix, typically oil and graphite, is dosed by valves that are very distant from the spraying point, therefore a variation in the quantity settings becomes effective only after many cycles, all those necessary for the new quantity of fluid to cover the whole way from valve to spraying point.

These, the spraying points, are copper pipes that, from a distribution block mounted on the subpress, are directioned and bent to target the specific points: the die figures, the punches etc.

In this way, every time the die is to be changed, it becomes necessary:

- To redirect the copper pipes, having every time to find the perfect position;

- To dedicate a lot of time to the set up operation.

And how is it made in the new generation of presses? Read more

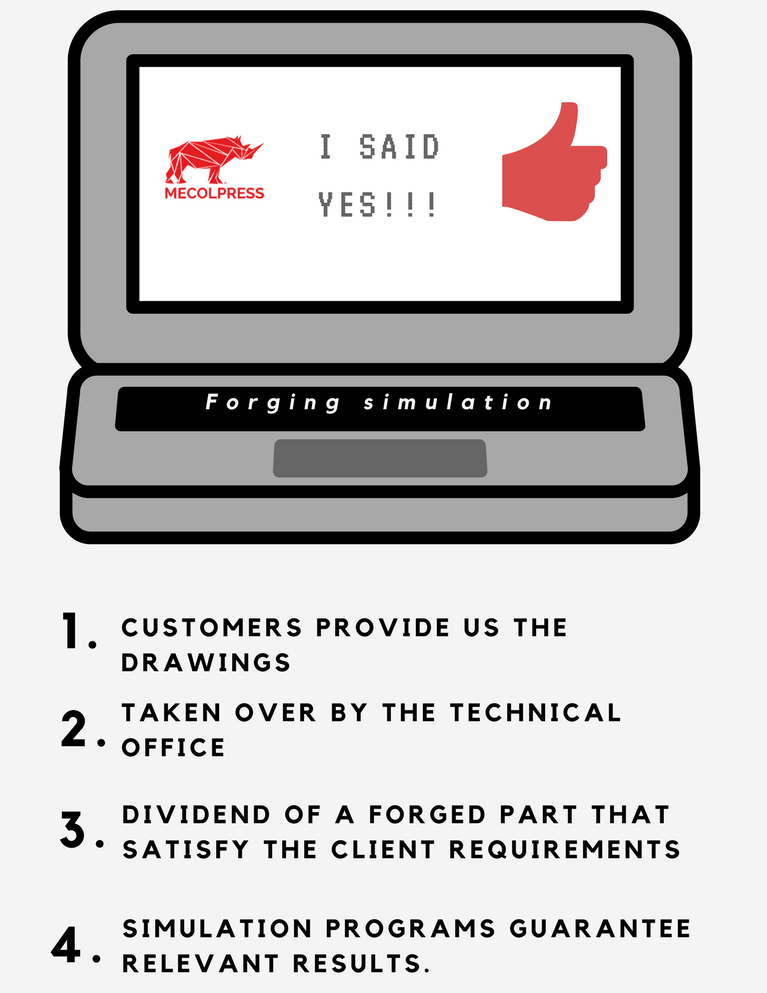

Forging simulation

Mecolpress sells turn-key forging plants.

This means to offer to the customer not only reliable and innovative machines, but competence on the forging product and process as well: the forging line has to work regularly, respecting the productivity level and granting stable quality. During the proposal phase, the careful evaluation of the parts to be forged is always a crucial element.

Traditionally, this activity was limited to the knowledge acquired thanks to many years of experience of a few key persons, so the evaluation of the parts was based on their “memory”, trying to remember the difficulties or solution identified in the past on similar parts. Precise technical parameters and data were seldom available and recorded, and therefore the surprises during the dies real tests were very frequent, in particular the forging forces were unknown and heavily influencing the final acceptance test of the machine.

Since the work flow programming is becoming more and more important to respect the planned delivery time and, at the end, to match the yearly turnover goals, the possibility to precisely foresee and plan the final activities of the forging line manufacturing is a key factor. Mecolpress since already five years use a hot forging simulation software that allows to analyse in the technical office the flow of the material in the die, and in this way to carry out a “virtual pre-acceptance” of the forging equipment. The goal is to anticipate as much as possible the forging difficulties and, to a higher level, to share among a wider number of persons and departments, the forging process knowledge: the aim is to go from “workshop expert man” to “forging mathematics”. For the sales department as well, this methodology brings clear advantages: the possibility to demonstrate in a transparent and easy-to-understand way the technical reasons on which the die design and identification of the suitable machine are based, is often a winning element to involve the customer in the project definition and in the last phases of the negotiation.

Usually the choice of the machine and the die design phases respect a standard sequence of steps:

- first, the customers provide us with the drawings of the forged and/or of the machined part,

- the Mecolpress sales personnel choose the most difficult or doubt ones and give these to the technical office.

- From this moment onward, subsequent FEM analysis are carried out, eventually suggesting as well to the customer modifications of details of the part, to reach the result of a forged piece that satisfy the (final) customer requirements and can be forged without defects thanks to the Mecolpress technology.

- The forging simulation software has been programmed with the Mecolpress machines specific dynamic characteristics and grant therefore highly reliable results.

After the die has been manufactured, the real forging phases in the production departments start.

Tthe first thing to do is to share the project parameters and machine program data between the technical office and the dies test department.

It is now that it is essential to understand if, and eventually how, the real behaviour of the material is deviating from the expected path, and to this extent the hydraulic forging machines have a special production cycle called “simulation steps” to produce several parts with pre-programmed partial completion steps, in particular with different cores penetration depths.

If this process is well managed and used, it easily lead to verify what foreseen in the computerized simulation, and also to identify the source of defects that might be found later in the finished parts, even in areas that are not easy to be seen at first sight.

Once the dies have been successfully tested in the production dept., the customer participate to the forging line final acceptance and can examine the forging process as proposed in the offer and agreed in the order.

To have anticipated the analysis of the piece and to share the forging process knowledge among the engineers of the technical office has reduced the variability of the length of the real tests duration and has brought to a much more precise and reliable calculation of the lead time of the machine in general.