Friction Srew Press – MECSPE 2020

Mecolpress will partecipate in MECSPE, at Fiere di Parma from 29 to 31 October 2020.

We exhibit the FPN 220 friction screw press.

For 19 editions MECSPE has been the greatest event focused on innovations for the manufacturing industry.

The numbers of Mecspe:

135.000 SQUARE METERS

56.498 VISITORS

2.306 EXHIBITORS

12 THEMATIC SHOWS:

360° innovation, the fair offers a complete overview of innovative materials, machines and technologies, Industry 4.0.

This event offers an interesting moment of meeting between companies, professionals and associations to build new opportunities for the manufacturing market.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

This ticket will allow you to access the exhibition area, participate in conferences, attend the demonstration areas and special initiatives of Mecspe 2020, and take advantage of free parking.

You can find us here:

MECOLPRESS

Hall 8 Non-ferrous materials and alloys, Stand M24.

For the 2020 edition of MECSPE, Mecolpress exhibits the FPN 220 Friction Screw Press

The screw presses like the one we bring to MECSPE are used for the hot forging of brass and steel parts, or with any type of material in general.

They are characterized by the production of solid pieces, or that require multiple forming steps.

Find out more by consulting the screw presses category on our blog.

We are therefore waiting for you at MECSPE!

MECSPE

Location: Fiere di Parma

Address: Viale delle Esposizioni, 393A – 43126 PARMA (PR)

Date: 29 – 31 October 2020 – Thursday, Friday, Saturday

Opening Hours: 9.00 – 18.00 (Thursday and Friday); 9.00 – 17.30 (Saturday)

Visitor entrances: Reception Sud, Est, Nord, Ovest

Visitor Parking: adjacent to the entrances

https://www.mecspe.com/en/magazine/

The excellence of technology applied to industry.

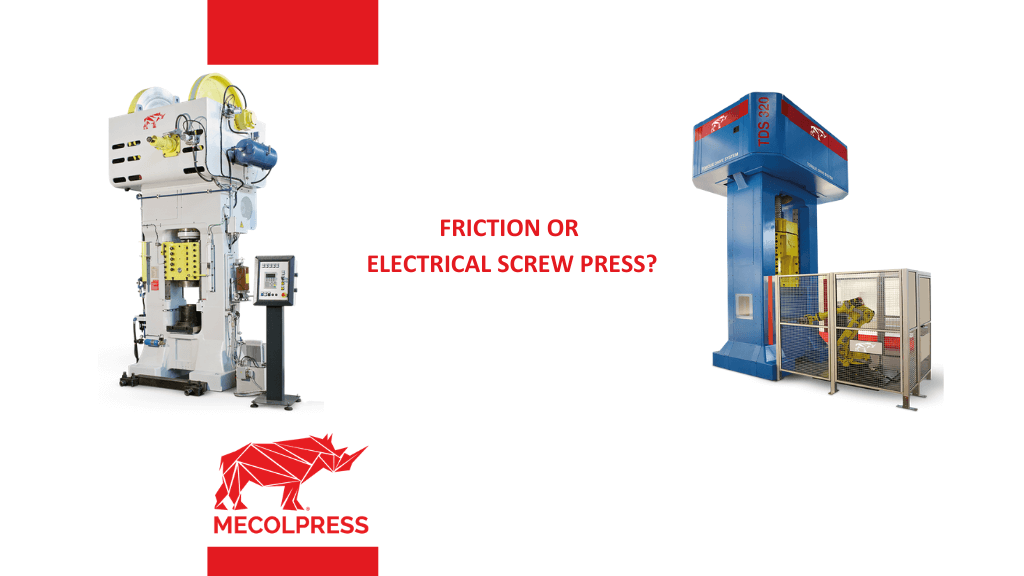

Friction or electrical screw press?

There are electrical or friction screw presses. Which to choose? The choice of the model is linked to the type of parts you want to forge, but also to the press performance. Discover the differences between these types of screw press by reading this article.

The mechanic friction machine is provided with a flywheel that rotates the screws clockwise or counterclockwise so that to let the slide go down or go up. In this case the transmission of the motion from the electric motor to the flywheel happens through the friction created on a leather belt. This model does not permit a direct control of the motor and of the flywheel, even if it presents considerable advantages in terms of energy saving. Indeed, a friction screw press has a medium consumption of about 40 KWh.

These presses require a smaller investment than the one of the screw presses with electrical servomotor, but they need the leather belt replacement, necessary for the slide movement when it wears.

Suitable for the hot forging of every type of material, the friction screw presses are used for the production of full parts.

This press, as opposed to the friction one differs for an electrical motor directly mounted on the flywheel, in the upper side of the machine, that rotates the screw. Thanks to this characteristic, the electrical screw press allows a better control of the productive process. Indeed, it is possible to check the descent and rise speed at any moment, to have direct feedback about the production of the machine and to calculate the necessary tonnage for the hot forging of parts you want to produce.

The electrical screw press requires more electrical energy, but its components wear less, and it is particularly indicated for the production of parts that require more strokes to be completed. In addition, it is possible to obtain much more energy with a reduced stroke, which does not always happen in the case of friction screw press. As a result, this machine has a rate of production slightly higher than a traditional machine.

The mechanical screw presses of Mecolpress TDS series are moreover provided with Calipso software, which is also developed by our company, that allows the data collection and recording in real time. In this way the end-user can do a process evaluation and intervene to optimize it.

Mecolpress proposes to its customers both friction screw presses and direct control with electrical servomotor control screw presses, developed to satisfy the different productive needs and suitable for the forging of full parts destined to sectors such as automotive, medical and sport one.