EXHIBITIONS 2022: MECOLPRESS AT BIEMH (Spain)

BIEMH Bilbao 2022

This event will be held at the Bilbao exhibition centre from 13 to 17 June 2022.

Mecolpress will present its latest technological innovations regarding metal forging.

Besides Spanish companies also international ones will be participating in this event, operating in sectors such as: metallurgy, welding, articles and equipment, machine tools, technological solutions, and much more.

You can find us in Pavilion n°5 Stand D34

Augmented Reality, the press just a click away

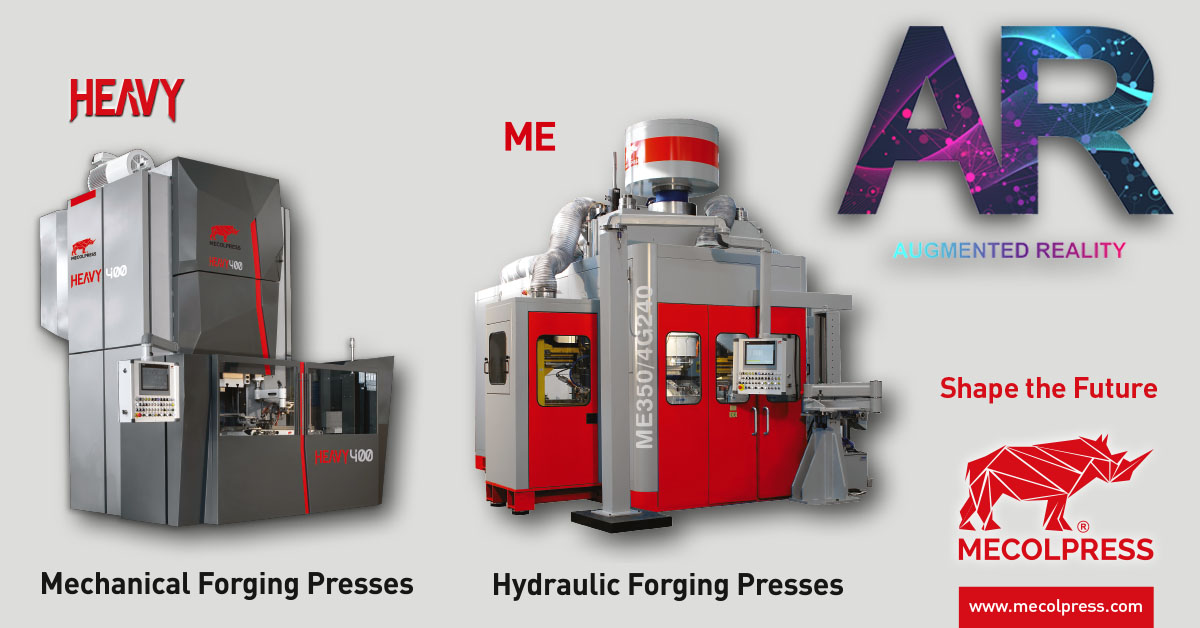

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

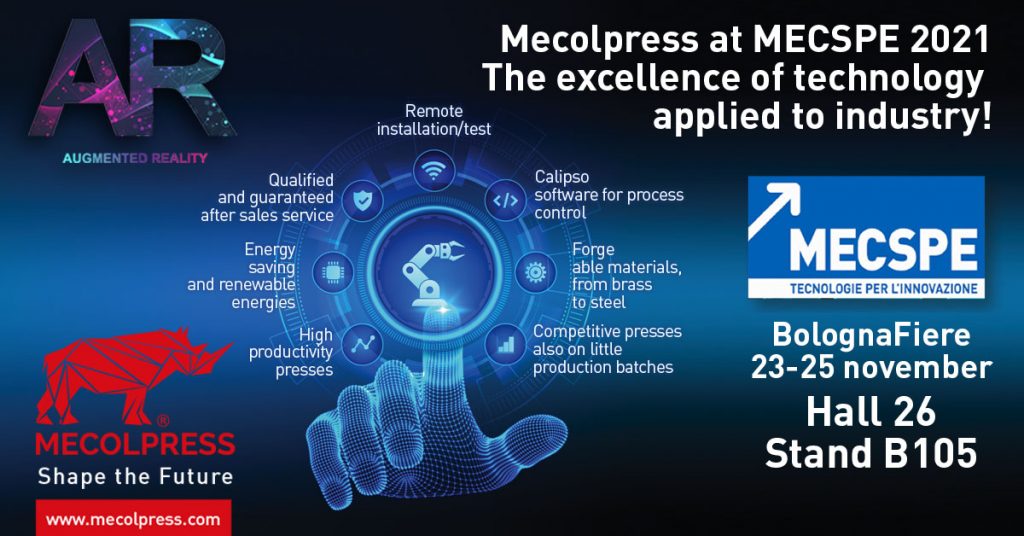

MECOLPRESS AT MECSPE 2021

THE EXCELLENCE OF TECHNOLOGY APPLIED TO INDUSTRY

It has been the most important event dedicated to innovations for the manufacturing industry and it counts 19 editions.

The fair will be held in Bologna from 23 to 25 November.

MECSPE, the main event in Italy on innovative technologies for manufacturing 4.0 industry promoted by Senaf, joins this outlook of restart and business confidence by following its commitment to support this sector and representing itself for 19 editions of over 2,300 exhibitors and trade associations.

This year’s appointment, rescheduled at BolognaFiere, from 23 to 25 November 2021, will have as its main theme “digitalization, training and sustainability”, subjects that visitors will be able to explore through 13 synergistic salons divided by thematic areas, demonstration of talent, commitment and creativity of Italian Companies.

A field, the industrial one, has always been supported by MECSPE which promotes fruitful collaborations between the various players in the supply chain, sharing visions and projects with them, as demonstrated by the historic partnerships with Confartigianato Meccanica and CNA Produzione.

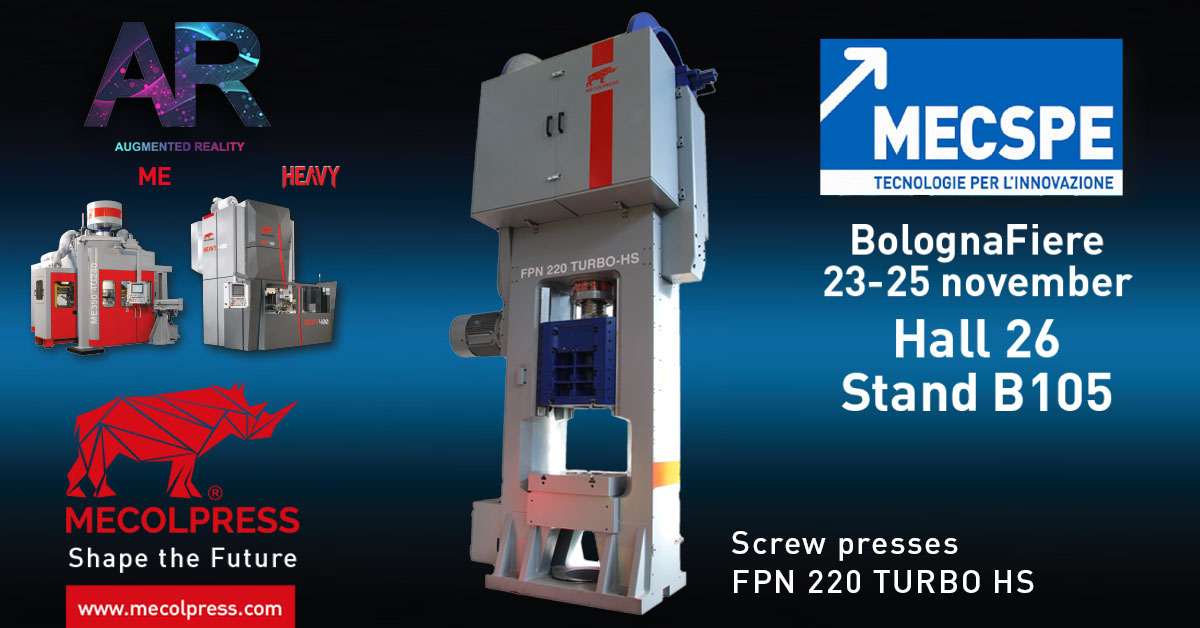

At MECSPE 2021 we will exhibit the FPN 220 Turbo HS screw press.

This is the best evidence of the outstanding performances of the OSTERWALDER screw presses, part of by Mecolpress family from more than 20 years.

These screw presses are particularly suitable for processes where high precision\tight tolerances of forged components are required, for example in the production of gears. They are suitable for hot forging of steel parts, but also of all other materials.

The TURBO version allows to reach higher speed, increasing productivity from 20% to 40%.

Augmented Reality, the press just a click away

In addition to the FPN Turbo screw press, it will be possible to view two other technologies thanks to the Augmented Reality: the ME Hydraulic and the Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

ForEMOst!

ForEMOst!

EMO is the worldwide exhibition of the machine tool, held in Italy and Germany, and that this year will take place in Milan at Fiera Milano Rho from the 4th to the 9th of October.

All the main international players of the manufacturing sector will take part in EMO MILANO 2021; so far there are more than 30 countries represented, covering all the segments that make up the world of the metalworking machines.

Undisputed leader in the trade fairs panorama, EMO represents the whole metalworking world in the best way, showing the best of vision and innovation.

Metal forming and metal cutting machine tools, robots, enabling technologies and automation, solutions for interconnected and digital factories, additive manufacturing will be among the key players of EMO MILANO 2021.

The exhibit is held in the entire Fieramilano Rho Exhibition centre, that can be easily reached with any transport means.

To guarantee visitors and exhibitors the participation in total safety in the exhibition, Fiera Milano Group has developed a Protocol for the safe conduct of trade fairs, in full compliance with the health rules and protocols issued at national level.

MECOLPRESS will participate with a “revolution” of the exhibition concept

Augmented Reality, the press just a click away

This technology allows to overlap multimedia information to the reality framed by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

A very powerful mean in the company communication field, and in this regard, the Augmented Reality has a strong impact on the customer experience, because it transforms the way in which companies interact with their customers.

In the trade fairs the Augmented Reality results to be very useful, both for the exhibitors and for the visitors who will be able to live a visual experience at 360-degrees.

Two will be the presses, chosen from the production range of MECOLPRESS, that will give birth to this innovative space of virtual reality, that will offer the possibility to see and to experience the functionalities of the represented machines.

We are waiting for you Hall 5 – Stand B29

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

Mecolpress, 50 years in the hot forging sector

This year Mecolpress has reached the goal of its first half century of activity by presenting a new continuous and discontinuous cycle press at EMO exhibition in Hannover, held last September.

In the present of Mecolpress there is also an investment in the world of electric scooters.

The video story by the management of Mecolpress:

Established in 1969 by Giulio Molinari, Giulio Barbisoni and Pietro Caggioli, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. A few years later, in 1973, the company acquired its current production site in Flero, in via Don Maestrini, initially extended over an area of 2,000 square meters, and then it expanded increasingly reaching 6,000 square meters in 1993. Today Mecolpress has acquired a second industrial area next to the first one where the construction of a warehouse is coming to an end, reaching a total area of 30,000 square meters.

In addition to the industrial area expansion, over the years Mecolpress has aimed higher and higher thanks to the acquisition of two important brands of the screw presses production: the Italian company, Dellavia (1993) and the Swiss company, Osterwalder (1998). The company has always distinguished itself as an avant-garde reality in the forging sector: remarkable are the production of the first continuous cycle mechanical press in 1983, the production of the first continuous cycle electronic press in 1993, the design and construction of the hydraulic press for hot forging of brass components without flash in 2008 and the presentation on the market of the screw press with direct drive motor in 2013.

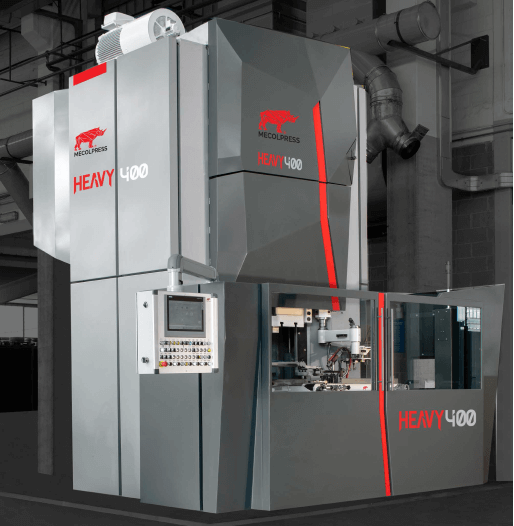

In September of this year, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

This new machine has an innovative and modern structure, more robust, and designed to simplify the control and maintenance for the operator. The automation and the dies lubrication of the machine was completely renewed, thanks to the addition of a bearing, that allows, among other things, for vibrations reducing and it is provided with a new intelligent software for the production process analysis and for predictive maintenance.

On 31st August, Mecolpress celebrated its first 50 years of activity by opening its doors to the families of the employees who work at the Flero site every day. In this first half century of activity, there have also been moments of sacrifices and difficulties, but the tenacity and determination of its founders allowed Mecolpress to emerge very quickly in a particular market such as the forging one.

The second generation played an important role in the history of the Rhinoceros, as well, in particular, during the economic crisis of 2008, when the company could make courageous decisions, expanding its business, pushing on the accelerator of innovation and research, trying to renew itself and pushing beyond the borders drawn by parents. Now the company has reached the maturity of an important reality that operates all over the world, where the glorious history of its beginnings coexists with the desire to get involved that has especially characterized with research and innovation the last years.

With the background generated by this mix of values, now also the third generation appears in the management panorama.

Watch the video of our Anniversary Party:

Mecolpress, a new adventure

In 2018 Mecolpress acquired the majority of the shares of ME Group, manufacturing company of electric scooters with an unique design, becoming the reference partner alongside the founders. The entry of Mecolpress formally coincided with the passage of ME Group from Innovative Start Up to Innovative SME. This formal transition was in fact also substantial, thanks to the contribution of Mecolpress from a financial point of view and above all from the point of view of know-how and industrial approach to the organisation of the company. ME is the first scooter in the world with a patented frame made of SMC (Sheet Moulding Compound), a compound of thermosetting resins with excellent performances in terms of strength and resistance in relation to its weight. This electric scooter can be recharged like a mobile phone: it can be fully recharged in 3-6 hours (depending on the battery charger used), connecting the scooter directly to a domestic outlet in the garage or office or extracting the battery.

The ME Start Edition version (sold out) was followed by the range available from the 2019 season: 2.5 kW moped model, 45 km/h top speed (limited by law) and 80 km range and 6 kW model with a speed of 80 km/h. Touch display, USB socket and a range of accessories in continuous evolution complete the equipment of ME.

Company numbers:

Mecolpress has grown over the years both in terms of volume of the industrial area and in terms of numbers. Starting from the employment situation: in 1985 Mecolpress had 29 employees, in 2018 it practically doubled its staff to 55 employees. Turnover and production are also growing: in 1985 the company turnover was just over 2.7 million euros. By 1995, turnover rose to 7.5 million euros and then the last available turnover (2018) exceeded 11.3 million euros.

Over the years production has also gone hand in hand with turnover increase. Today Mecolpress has 559 customers in 59 countries worldwide. All over the world there are 1126 Mecolpress machines, including screw presses (101), mechanical presses (806), hydraulic presses (40) and trimming machines (179). Most of them (763) are located in Europe, but the Flero-based company has also exported in Africa (62), Americas (103) and Asia (198).

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..) in the order of more than 1,000 units, bringing the total production of machinery and spare parts to 2183 pieces.

HEAVY SERIES MECHANICAL PRESSES

Mecolpress, at the EMO exhibition in Hannover which took place last September, officially presented the new series of eccentric continuous cycle mechanical presses, the HEAVY series.

Based on the experience accumulated over 50 years of designing and manufacturing presses for hot forging metal, we have succeeded in creating a totally renewed mechanical press.

We are sure that our new project will mark the beginning of a new era for hot forging!

What are the main strengths of the new HEAVY mechanical presses?

-

- A structure that is certainly innovative and modern, more robust and designed to simplify control and maintenance;

- Fully revised die automation and lubrication;

- Our innovative hydraulic cushion, the Soft-Impact, which allows to achieve important results including for example the possibility of vibrations reducing;

- The updated version of our intelligent Calipso software, for the analysis of the production process and for predictive maintenance.

Let's analyse the features in detail:

STRUCTURE

The structure of the machine is made in such a way as to separate the dangerous area (moving parts and die area) from the areas accessible to the operator for adjustments and ordinary maintenance, through front protections and soundproofing material casings, as required by CE standards.

Directly on the vertical part of the forging area, the fume extraction is obtained through metal ducts with connection to the customer’s centralized system.

The control unit for centralized lubrication of the press, the regulators of the pneumatic system and of the die lubrication system and the electrical equipment are inserted in large protected cabinets and easily accessible to the operator, not reached by the fumes and the oil of die lubrication .

The assembly of the main parts to the machine is designed to simplify inspection and maintenance.

COMMAND GROUP

It includes a compact transmission coaxial to the eccentric shaft including:

– Combined flywheel and reduction unit;

– Combined Hydraulic Brake-Clutch Group, equipped with progressive piston to mitigate shocks and transmission vibrations due to engagement and braking;

– Control valve of the Brake-Clutch group with progressive engagement and braking control;

– Double gear coupling between eccentric shaft and transmission to avoid the transmission of shocks from the crank mechanism to the control unit;

– Main motor with encoder and closed loop control, allows the slow movement of the press for tooling, “Inching mode”.

The flywheel motor system has been completely revised to obtain better resolution and precision in speed control, greater reactivity in the recovery of energy after forging.

A safe speed limit control is foreseen with open front protection, during the set-up phases and a check of a possible excessive slowing down of the machine (for example due to a too large billet).

The motor cooling is constantly ensured regardless of the motor speed, this allows to always guarantee maximum performance.

We have provided an interesting option: the energy that the motor returns to the inverter during the slowdown phases, is put back into the network and not dissipated in heat; in practice it translates into a lower consumption of electricity!

SLIDE

Also the slide has been revised, we have foreseen a motorized adjustment of the vertical light and an extraction bar with hydraulic control.

The sliding skids are oriented radially to the machine axis to reduce the variation of the tolerances with changing temperatures.

The hydraulic system for protection against overload is also inserted in the slide, which is essential for forging on the bottom.

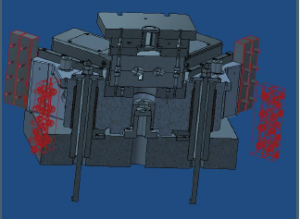

GE EQUIPMENT

– Possibility of mounting the lower punch also with “SOFT IMPACT” cushion,

– Water cooled upper die holder,

– Up to 8 points of lubrication from the lower die holder,

– Up to 4 points of lubrication from the upper die holder,

– Easy equipment change. It is extracted by unlocking the top with pistons that allow extraction on a ball guide.

– Possibility of mounting the motorized adjustment of the punch stroke.

For the HEAVY400 the GE26 is foreseen, which has the following specific features:

– Dies 290 x 290 mm

– 110 mm punch stroke

Thanks to our Extruder Group you can save up to 40% of the material compared to the full forging modes! Check out the details here

“SOFT IMPACT” CUSHION

1000 kN hydraulic cushion with complete electronic management, it allows to check the punch height, in addition to limiting the mechanical shock due to the impact between the dies.

The Soft Impact cushion is an important innovation that we have been making for a couple of years, and that is proving to be truly appreciated. Read here to learn more about how it works.

BRCE LOADING DEVICE

The 2-axis rotary loading arm driven by brushless motors has the load angle of the clamp at 45 °, aligned with the dies centre;

The 400 mm vertical stroke allows you to manage any type of equipment without manually changing the position of the arm.

PBSE DISCHARGE DEVICE

The discharge chute has been designed to avoid dents to the forged part; driven by a motor brushless, the unloading arm allows automatic adjustment of the position.

DIE LUBRICATION

We have provided up to 20 lubrication points and 2 dies blowing points, an open and flexible configuration for each type of die and tool.

Also interesting is the possibility of adjusting the amount of oil from the panel, without need of manual adjustments on the machine and on the control unit.

From every point it is possible to blow air to clean / cool the die before every lubrication.

The press is able to warn in advance when it is necessary to fill the hydraulic unit, in order to avoid a machine stop due to lack of fluid.

A digital sensor allows the control of the fluid temperature, the operator can start the production only when the oil is at the correct temperature, an essential requirement for a correct and constant lubrication.

An inverter for pump speed adjustment prevents overpressure peaks and oil dripping when the pump starts with oil still cold; automatically adjusts the oil flow rate according to the quantity needed for use; prevents overheating of the oil in the control unit.

Our lubrication system, unlike the systems marketed up to now, eliminates the problem of the quantity of oil usable for each individual nozzle.

Competitive lubrication systems load a limited amount of oil into a tube and then blow it off with compressed air.

This ensures that 70% of the sprayed lubricant is used only in the first moment of lubrication, while in the remaining cycle the quantity of lubricant decreases until it is completely zeroed.

On the other hand, our lubrication system allows continuous and constant mixing directly at the exit point of the pipe, through our system we can cool and lubricate the dies from the same pipe without affecting the programmed oil quantity.

ELECTRICAL CONFIGURATION

The 24vcc circuits are protected by auxiliary electronic devices, able to provide a quick diagnosis of any short circuits or overloads (also through Teleservice).

This is a very interesting aspect because it allows a greater reliability of the system and a service life up to 10 times greater than normal technology!

The cables are in PUR, protected by steel sheaths and silicone protections against flames, specific for use even in environments deemed aggressive.

OPERATOR INTERFACE

The Operator Panel is a 15 ″ Siemens Touch Panel to better manage machine data, you can save up to 1000 recipes! And have an alarm history with up to 10,000 events.

Obviously, through the proper configuration of our software, you can receive valuable reports to carry out preventive maintenance.

Another practical example is the notepad function, thanks to which the operator can then write important information and his personal notes, added to each production recipe.

It is possible to obtain a production report, a secure management by 4-level password with autologon function, and much more.

Finally, the movable panel allows close controls on the machine, possibility of movement and programming with front or rear open protection, close to the die (eg die lubrication).

EMO 2019: We unveil the technology of the future!

Mecolpress is ready for EMO 2019, the most important metalworking machinery fair, in Hannover from September 16th to 21st.

Mecolpress has always participated in EMO, the leading trade fair for the metalworking sector.

At each edition we always present some innovations, and this year more than ever!

On the Mecolpress stand there will be the possibility to see 2 machines running!

1- THE BRAND NEW HEAVY 400

Mecolpress will officially present the new HEAVY series of continuous cycle eccentric presses at EMO2019!

Its main features are:

- an extremely innovative and modern structure, more robust and also designed with an eye to ease and accessibility for maintenance and to safety;

- we have completely renewed die automation and lubrication;

- we have mounted a special hydraulic cushion that enhances the ability to forge cored parts, as well as to strongly reduce vibrations and noise;

- as on all our presses, also on the HEAVY series is installed Calipso, the intelligent software of Mecolpress for the analysis of the production process and for predictive maintenance.

The Mecolpress HEAVY Series represents the state of the art in hot forging with eccentric presses and can mount all the most modern accessories, production, programming and control systems.

2- The ME100/4L30 superfast – high productivity hydraulic press.

It is a compact machine, dedicated to the forging of small complex pieces, with an extremely high productivity.

This machine is the latest model of the now known and appreciated Mecolpress ME hydraulic presses, installed all over the world, from Japan to Mexico, from Korea and from China to Germany and Italy.

ME hydraulic presses have been for years a real innovation in the world of hot forging. They allow printing without flash thus significantly reducing material waste.

The ME100 / 4L30, like all Mecolpress hydraulic presses, is equipped with a powerful statistical process control software developed by us, called Calipso.

As stated by the official Hannover Magazine, this year EMO will focus more and more on digitization, with many insights and eyes still on the subject of Industry 4.

Among the most interesting aspects of Industry 4.0 there is undoubtedly the development of the so-called “platform economies”, also Mecolpress in this regard will present a new way of experiencing hot forging machines: connected in the cloud the press becomes intelligent, smart and easily monitored!

We will demonstrate how it is possible to integrate our presses with cloud or local applications that allow to carry out analysis of multiple operating and process parameters, thus representing, through dashboards, a real-time visualization for an optimal understanding of the data collected by the machine.

We will present all this at EMO 2019,

follow the event on our social media channels, we will soon reveal important news!