Hot forging in the fashion sector

Hot forging presses are also used in the fashion industry manufacturing.

The worldwide fashion sector is characterized by extremely significant business volumes: around 3 thousand billion euros and it employs 50 million people.

Italy is one of main districts for the fashion industry with historic brands and production chains deeply rooted in the territory.

The sector is affected by global uncertainties linked to inflation, geopolitical tensions, post-Covid recovery but double-digit growth is estimated in the coming years. The increase in business volume is possible thanks to a high dynamism full of creativity and style which canalizes an important flow of news and innovations every season.

The digitalization of sales channels and operational departments and the near-shoring approach have created the need to make the manufacturing process increasingly productive and efficient.

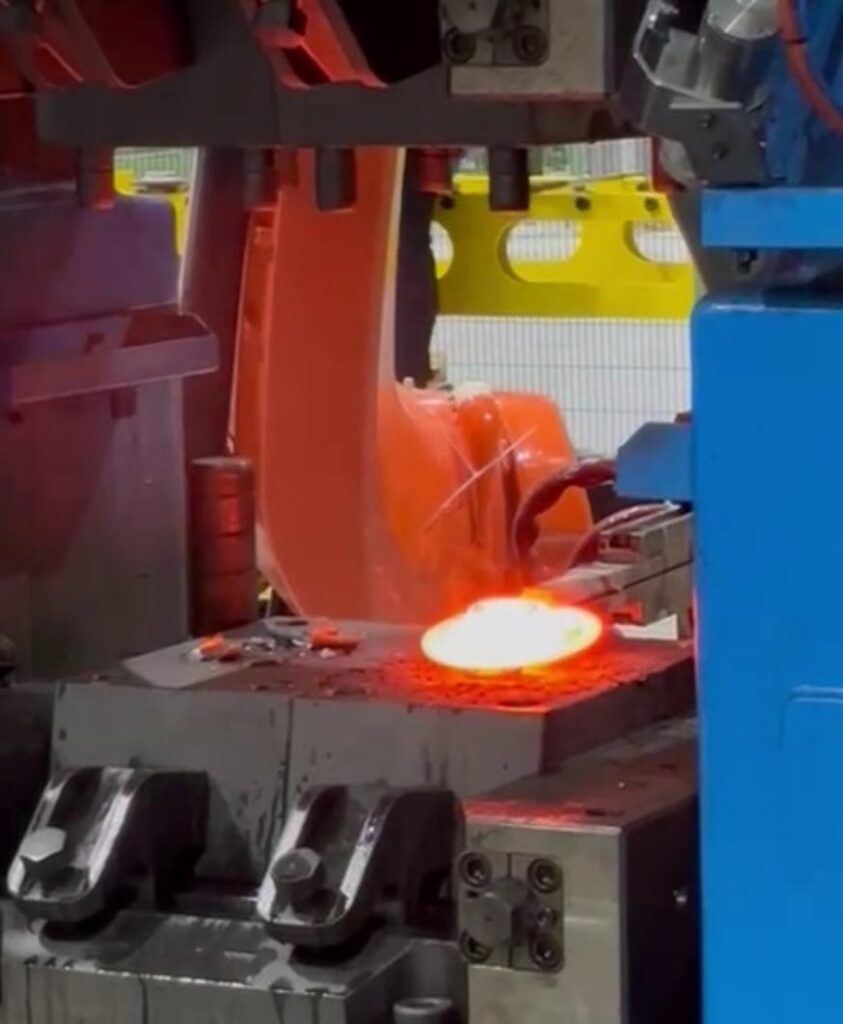

Metals hot forging is a key operation to characterize fashion products and accessories. The logos of the major brands applied on bags, shoes, clothes and belts are made through hot forging and then finished with other downstream processes.

Mecolpress has been the protagonist of this continuous growth process, offering technologically advanced forging solutions with the aim of:

- Increasing production capacity up to 1500 pieces per hour;

- Reducing machine downtimes due to maintenance and tool changes (availability >95%);

- Reducing the consumption of materials, energy and CO2 emissions by 50% (GREEN TECHNOLOGY Industry 5.0);

- Allowing the digital communication between production line and company system and remote diagnostic access (Industry 4.0);

- Flexibility in forging products of different sizes and materials (steel/brass/aluminium);

- Increasing the safety of the production line by reducing human intervention (industry 5.0).

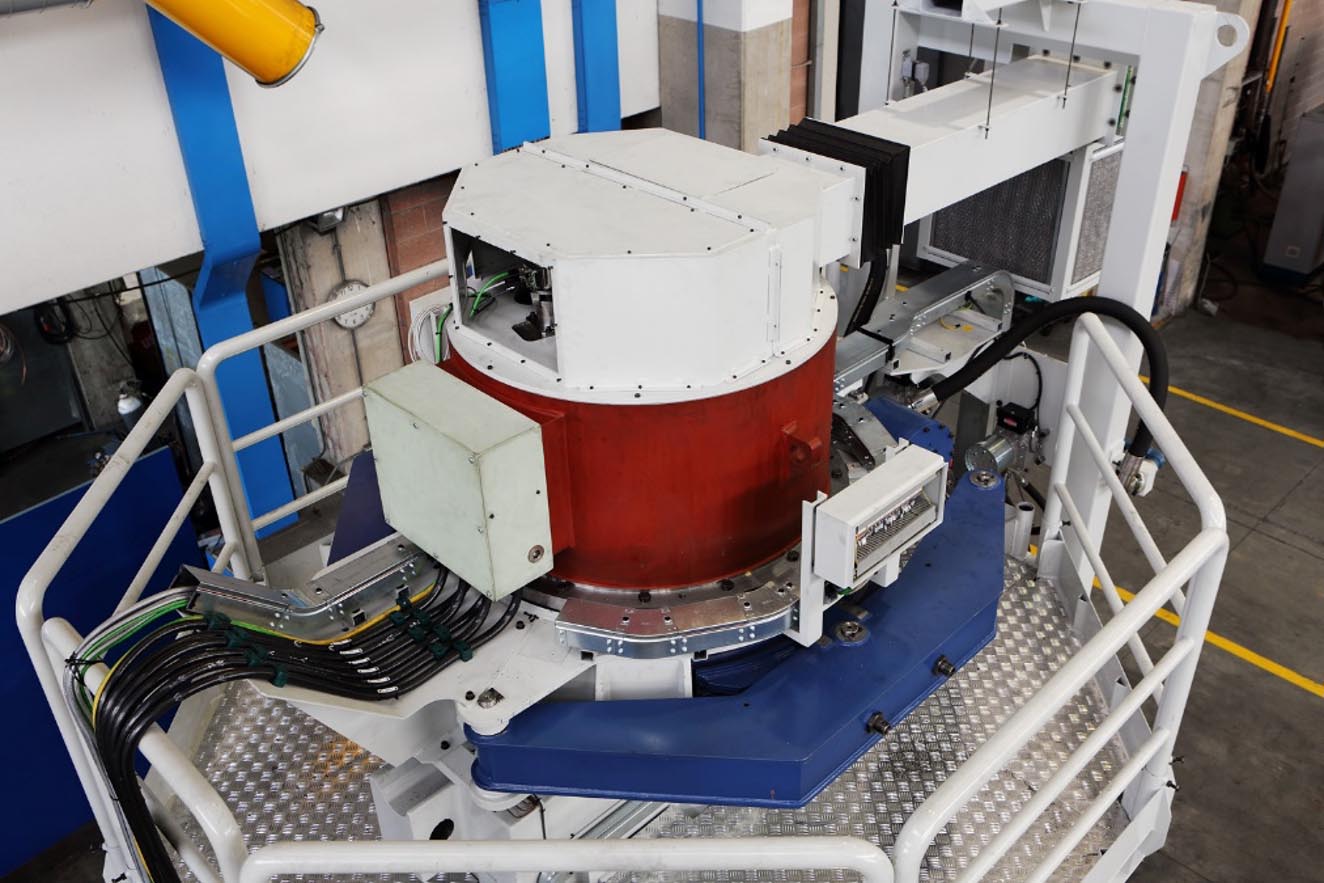

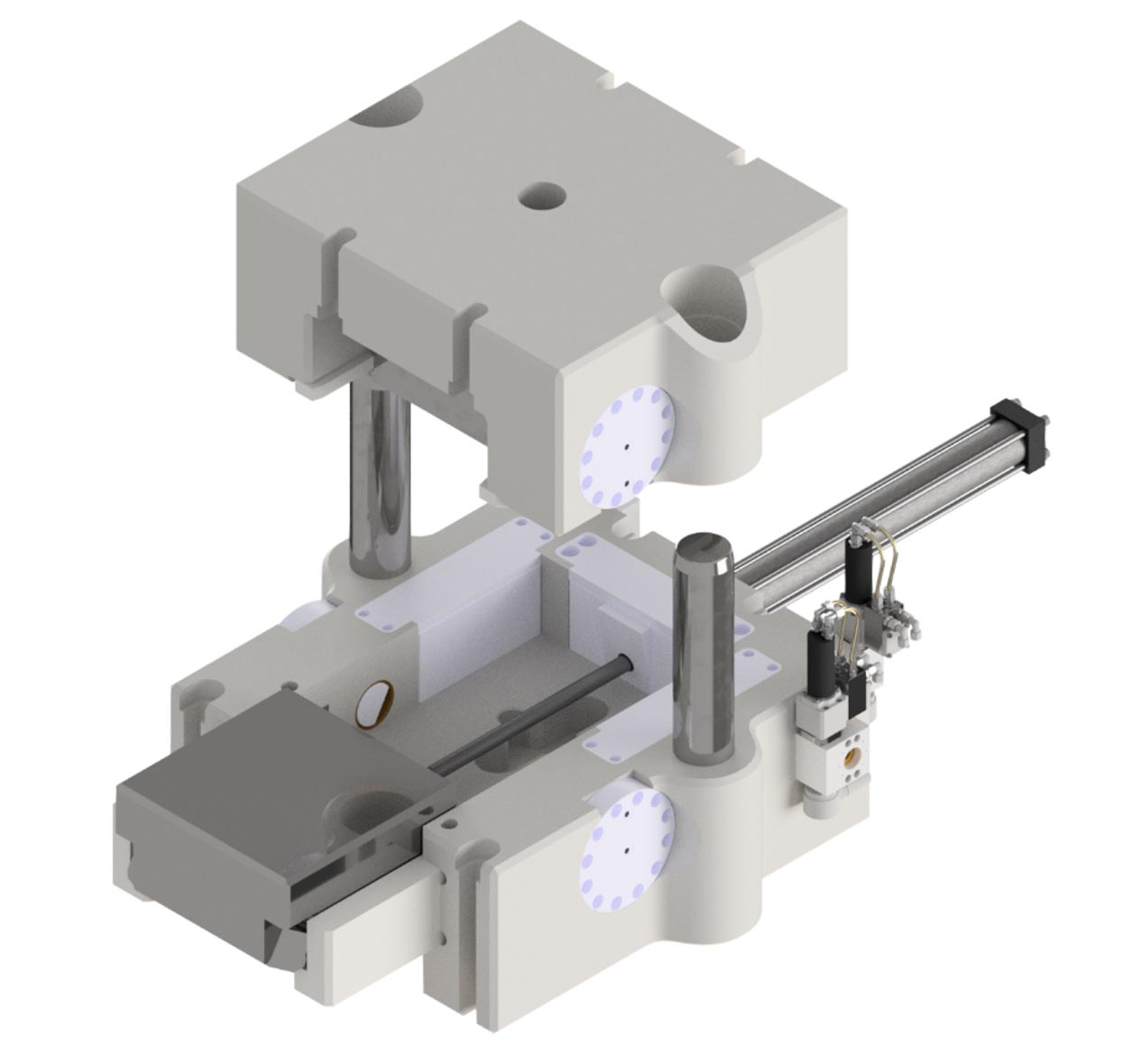

TDS Electrical Torque-Driven Screw presses

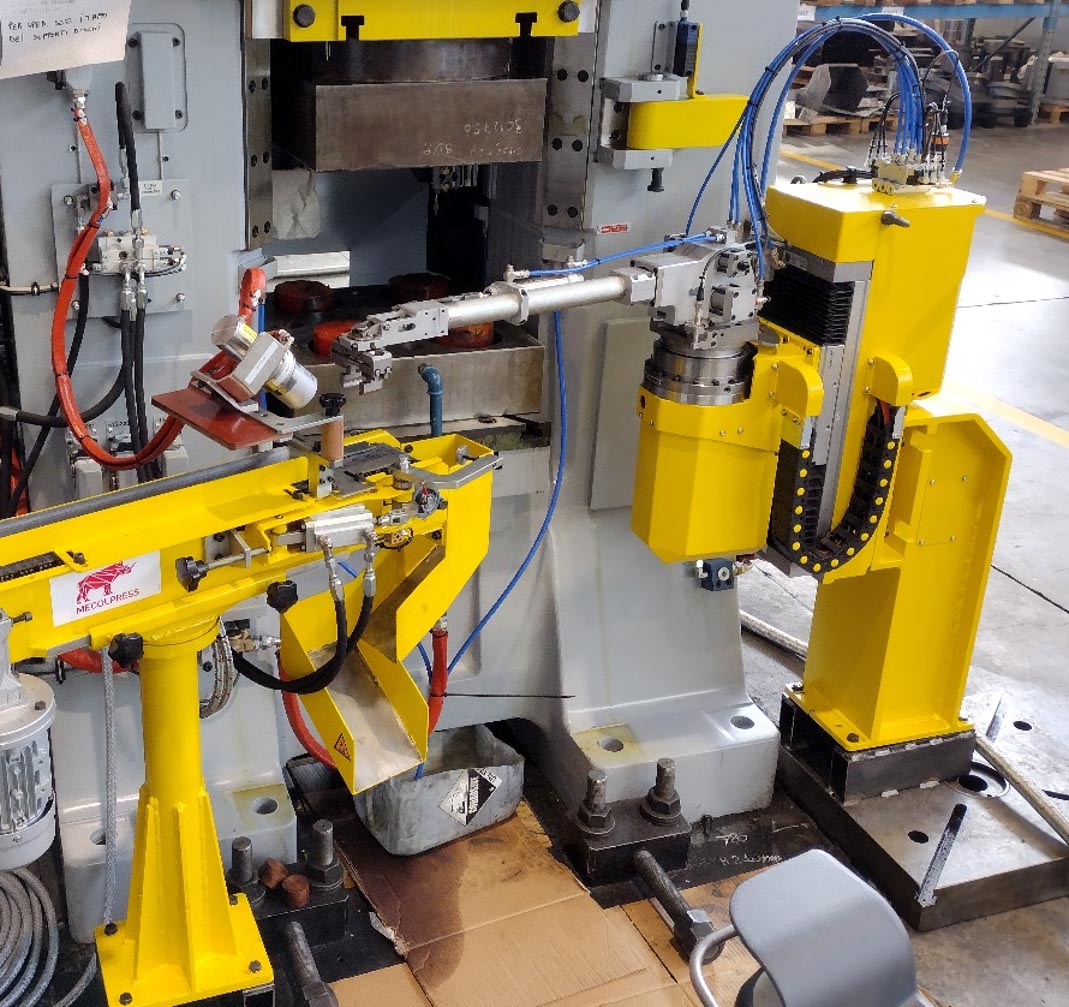

TDS Electrical Torque-Driven Screw presses result to be particularly suitable for the hot forging of parts destined to fashion sector.

Here below the 4 strong points that make many customers to prefer these hot forging screw presses:

- Cycle time does not dependent on forging energy => always optimized productivity

- Reduction of friction parts => less maintenance and less energy consumption

- Flexibility in energy settings => production flexibility for product size and type of material (brass, steel, aluminium) and reduction in dies wear

- Energy recovery of braking energy => reduction in energy consumption

Click on the image to enlarge

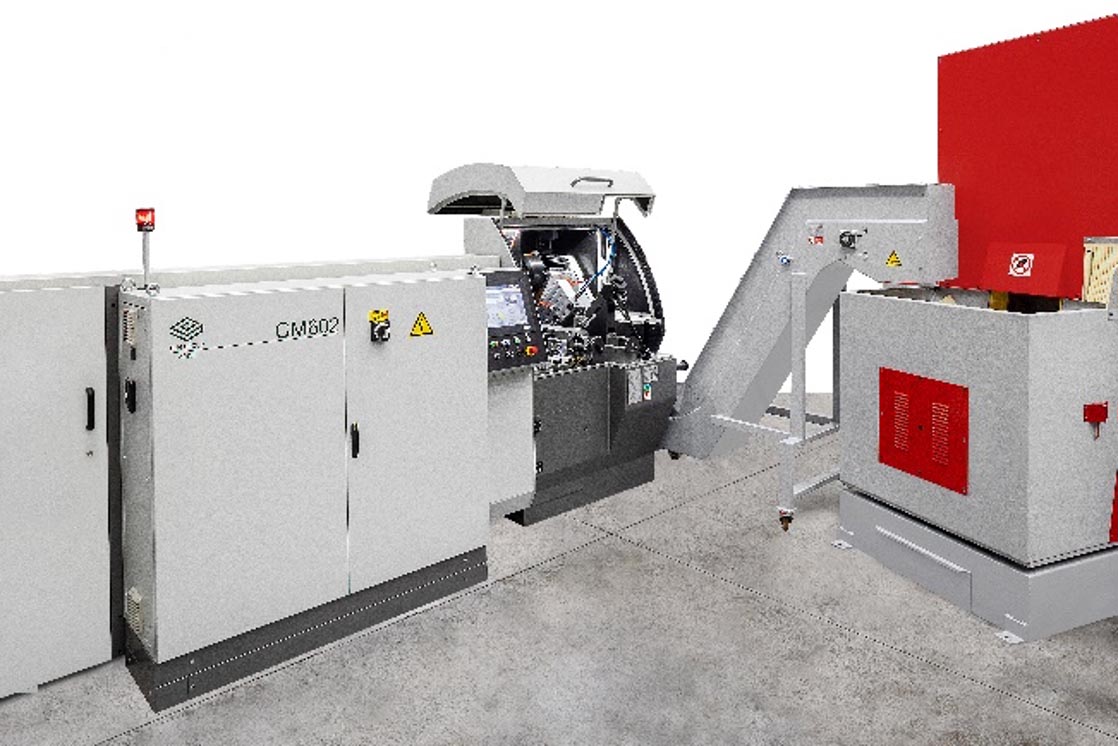

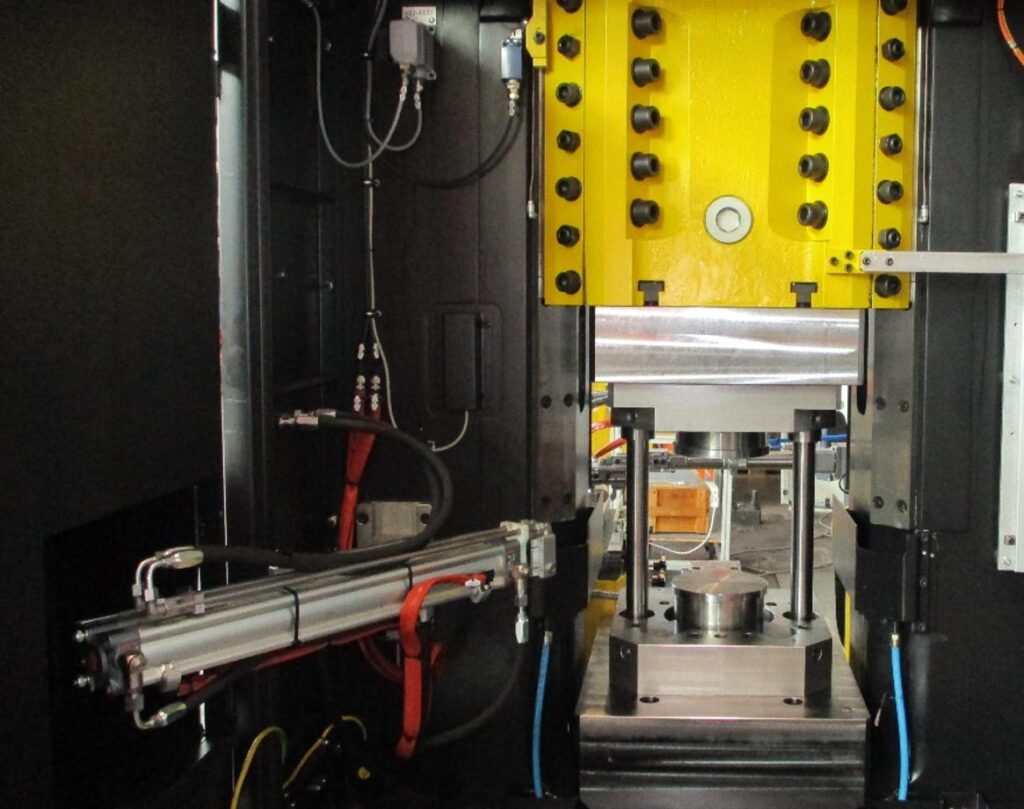

Complete forging lines integration

Even in the fashion sector, the frequent request is to have complete forging lines.

We can supply the line following the customer need, so in addition to the hot forging press, we integrate the cutting, heating, forging and deburring of the forged pieces.

Click on the image to enlarge

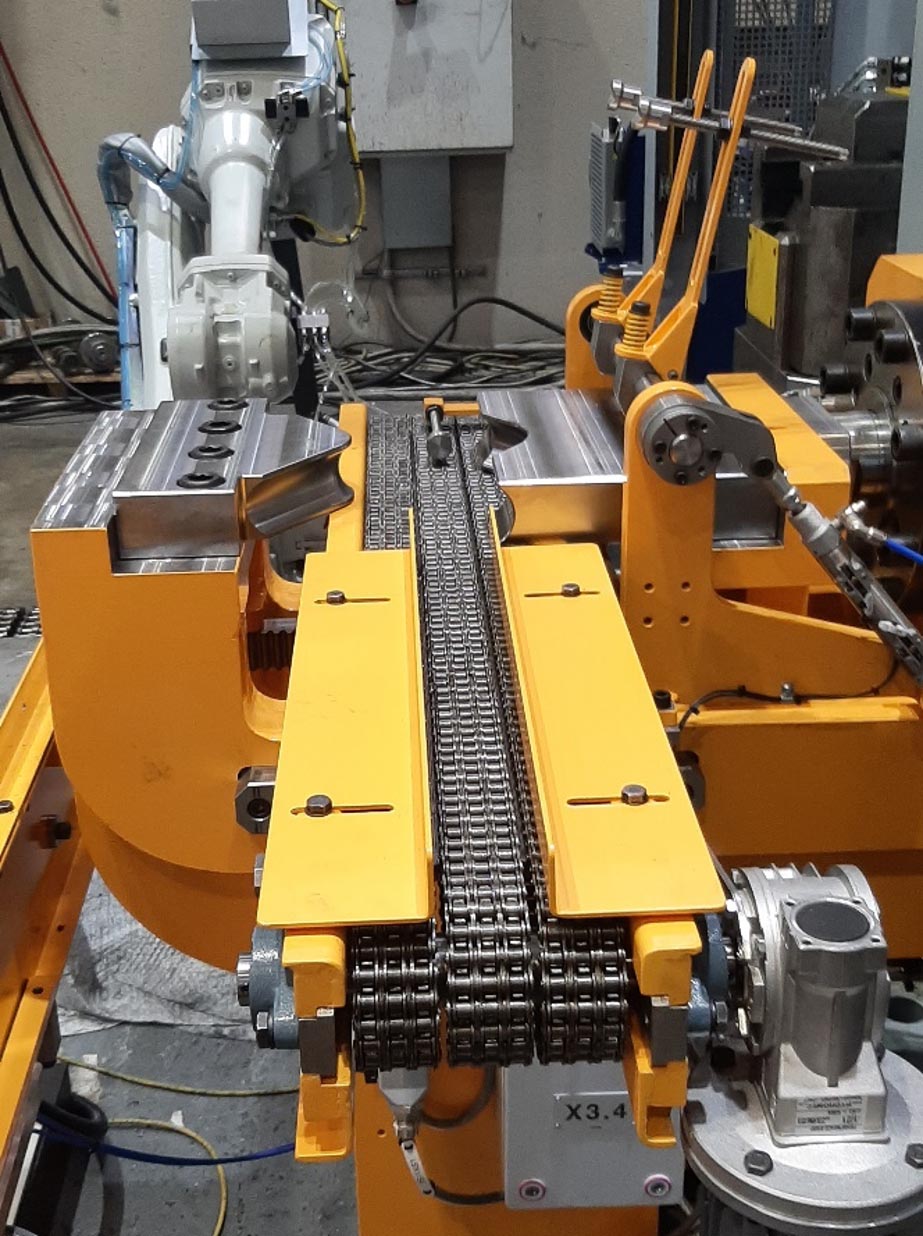

The presses for forging of parts destined to fashion sector have to optimize the process phases:

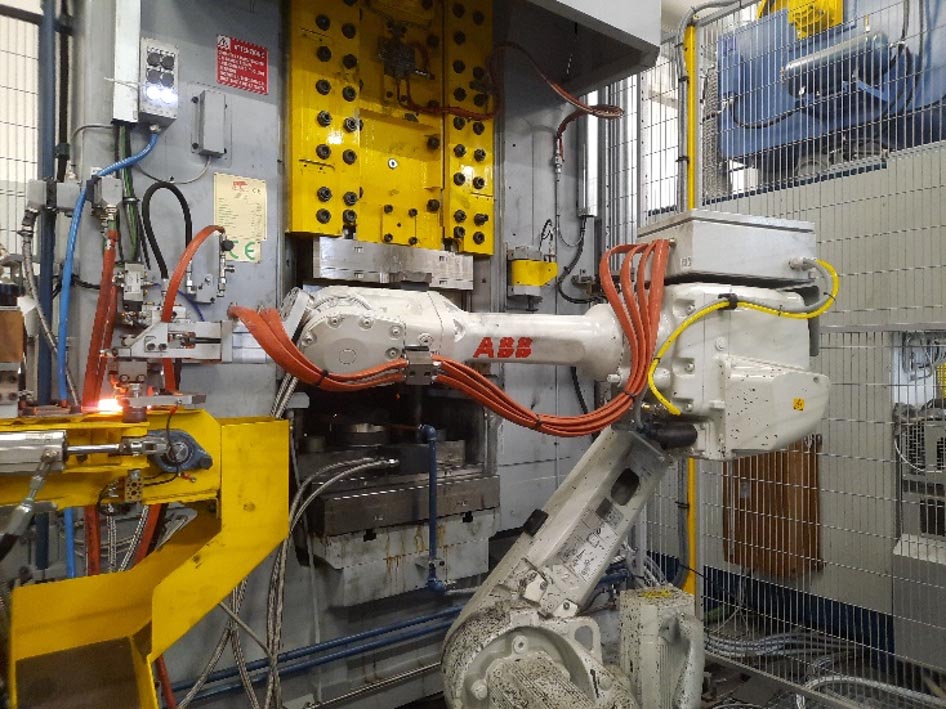

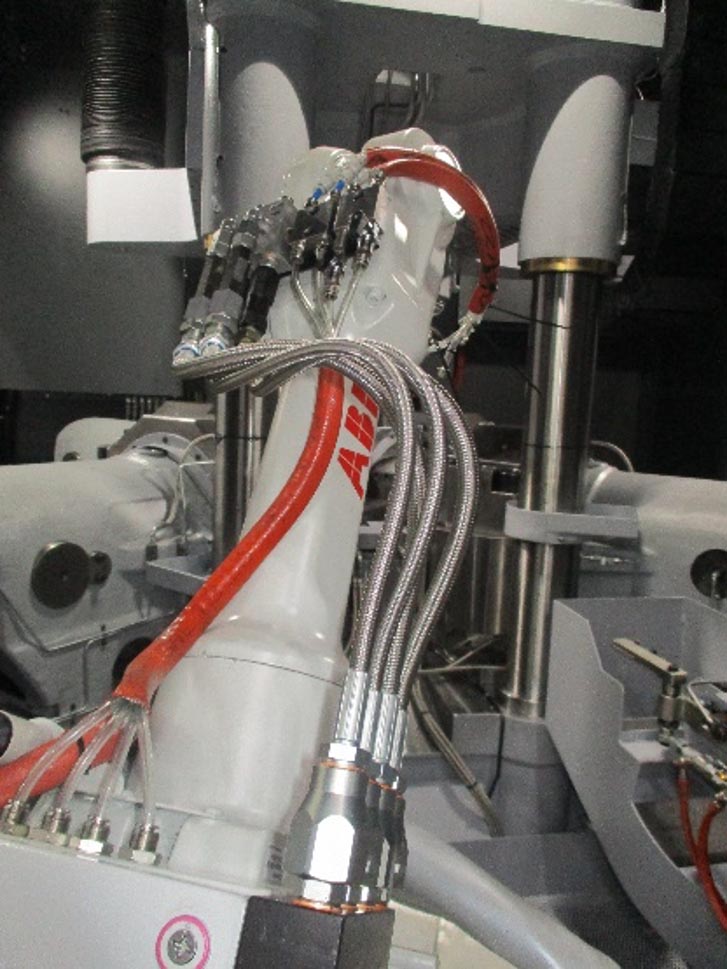

Automation of machine loading and unloading

We underlined the importance of automating the loading and unloading phases of pieces. The presses must include certain solutions to guarantee maximum performance:

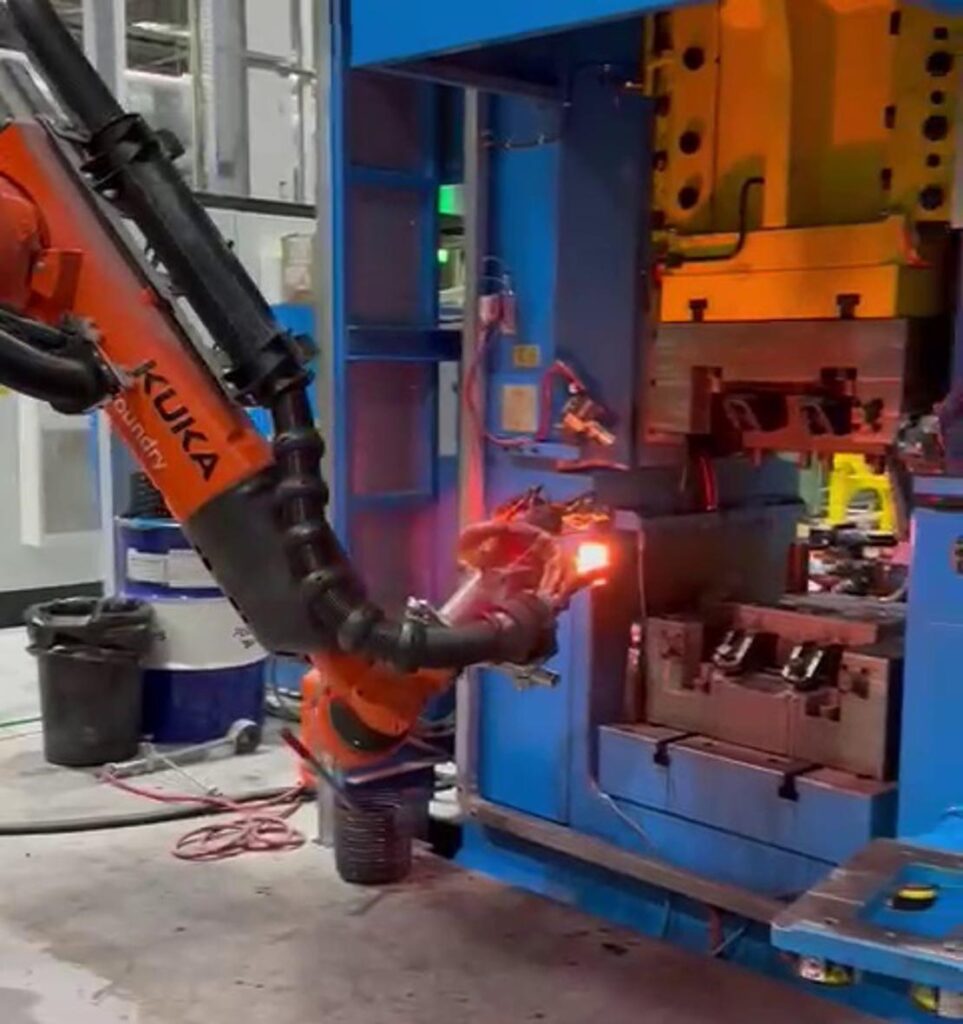

- High-speed Cartesian systems for heated material loading.

- Flexible anthropomorphic robots for heated material loading.

- Unloading of the forged product via air blow to avoid sliding and contact defects.

- Folding of the material to be forged to have a shape as close as possible to the forged parts and to reduce material consumption.

- Possibility of different shapes of the starting material from the traditional round billet to customized shapes (letters, symbols, …).

Click on the image to enlarge

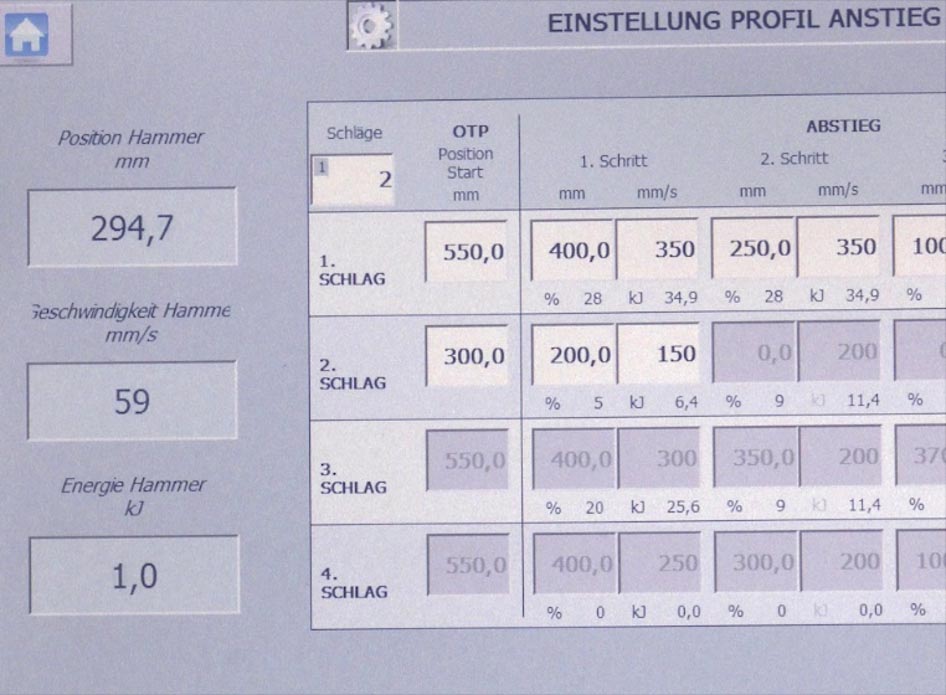

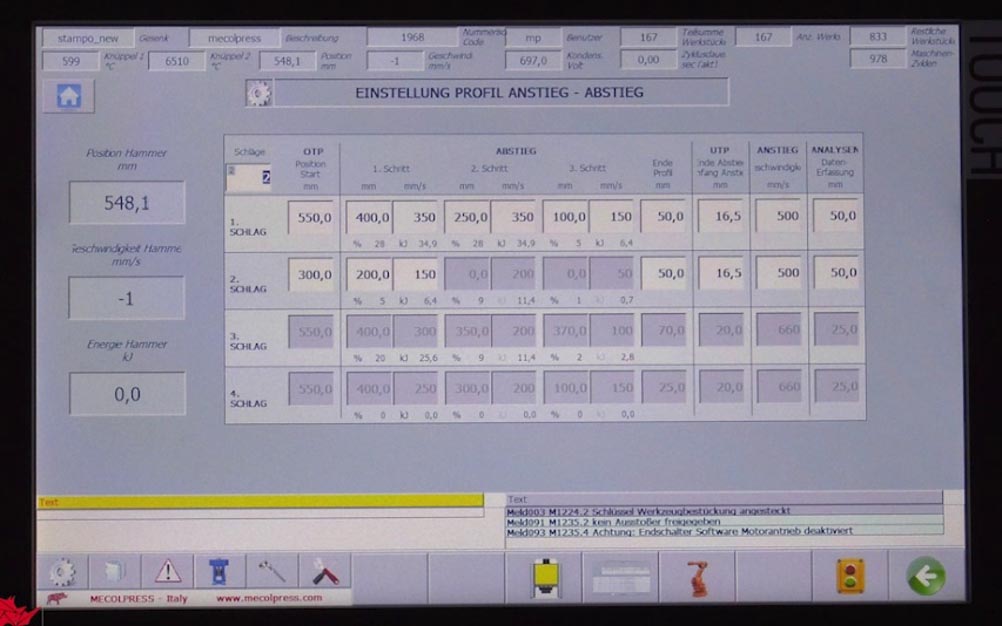

Productive process data control system

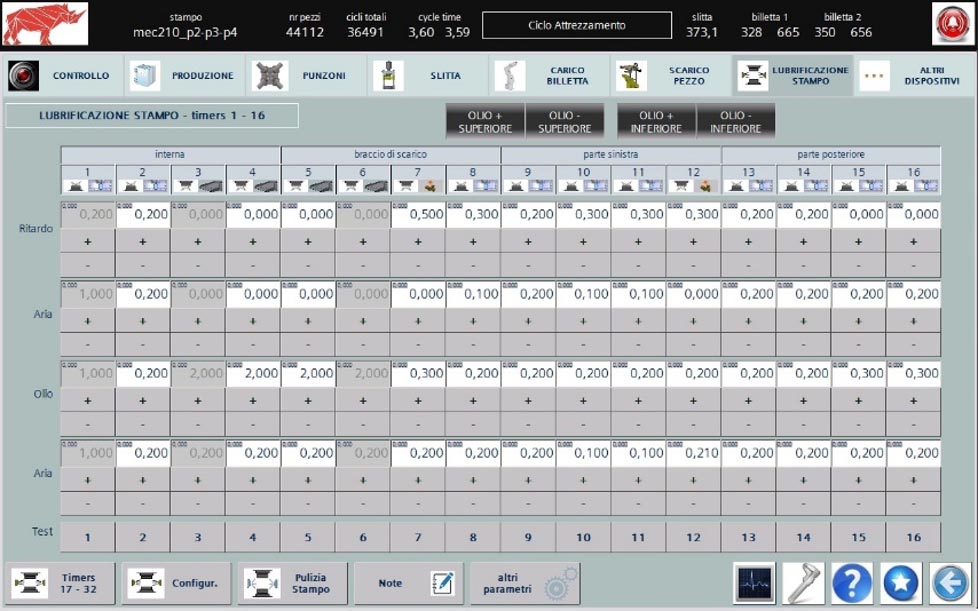

An important solution to take into consideration to start a successful hot forging project for parts in the fashion sector is certainly to equip yourself with a control system of the productive process.

Mecolpress Calipso Software allows to monitor and to adjust the data connected to forging process, and it presents numerous advantages, among which:

- Based on HMI architecture complete with touch screen display

- Functioning parameters of the press and of the auxiliaries that can be inserted from the display.

- For each forging cycle, the main parameters are saved for collection and analysis.

- Integrable with company MES/MRP systems.

- Remote access for diagnostics and problems solving

Click on the image to enlarge

Dies lubrication

The proper dies lubrication makes the difference for a successful hot forging process.

A correct lubrication does not mean a lot of lubrication, but it must be properly dosed, the most suitable lubricants must be chosen based on the metal to be forged and the required piece.

We propose:

- Automatic air-oil lubrication unit managed by the control panel.

- Up to 30 lubrication points.

- Automated lubrication arm synchronized with the forging cycle.

Click on the image to enlarge

Dies changing system

To allow a quick unlocking, the die holder has been optimized, and the auxiliary arm becomes essential for bringing the dies out of the working area of the press.

Click on the image to enlarge

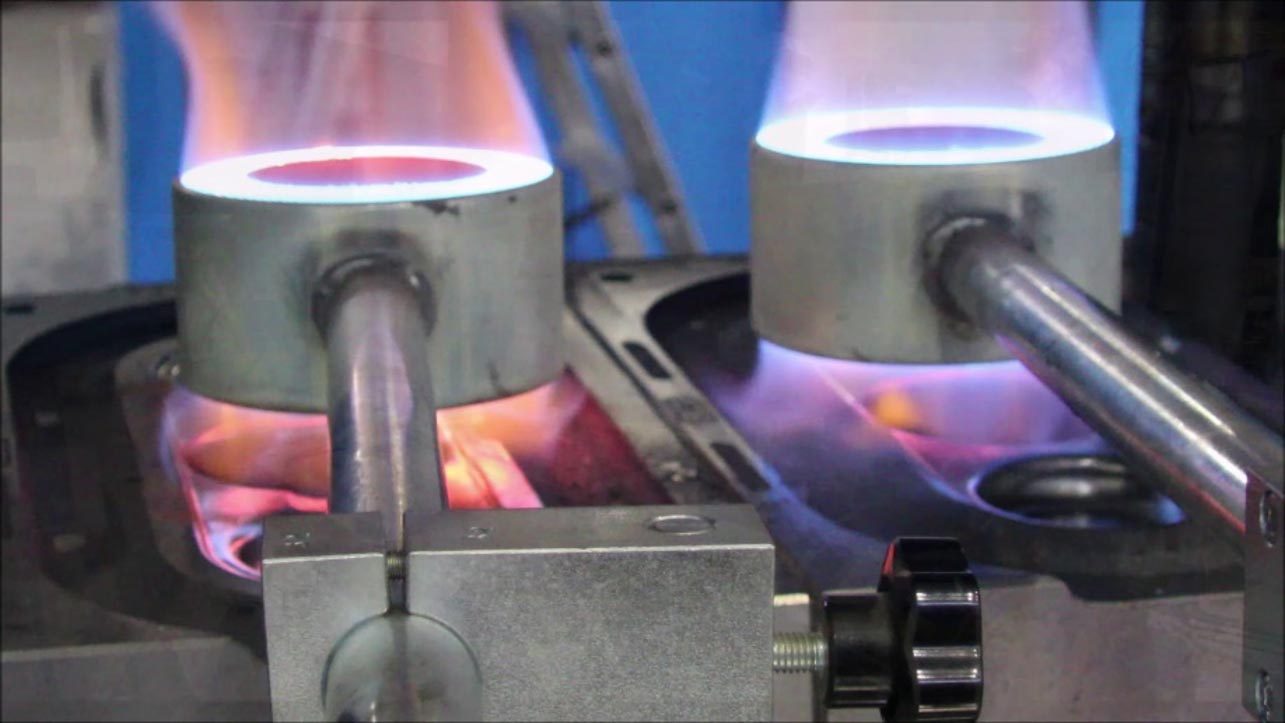

Dies pre-heating

This is an important phase of the hot forging productive process that foresees the use of modern induction technologies avoiding open flames or CO2 emissions.

In the fashion sector, therefore, hot forging presses and related devices are widely used.

It is always important to develop an accurate and successful forging project to maximize profits and reduce waste.

MCE EXHIBITION IN MILAN + OPEN DAYS IN MECOLPRESS

MCE EXHIBITION IN MILAN

For over 60 years MCE – Mostra Convegno Expocomfort (Milan) has been a key event for innovative air conditioning and energy efficiency technologies.

Companies that design, build and install systems for the heating and air conditioning of industrial, civil and commercial environments meet to exchange experiences, find new Customers and strengthen collaborative relationships.

The value of the global HVAC market is estimated at more than 200 billion dollars and is expected to reach close to 300 billion in 2027. The increase in “smart” applications in the construction of buildings, the demand for increasingly efficient systems to deal with growth in energy costs, the greater demand for cooling systems in areas where they were not previously necessary, drive this growth in value.

INNOVATION, SUSTAINABILITY and ENERGY EFFICIENCY will be the cornerstones of this edition which will combine digital events and in-person meetings. The former facilitate the reduction of distances and communication ease, the latter allow us to consolidate relationships and better understand needs.

Looking forward to meeting you at MCE – Mostra Convegno Expocomfort

12-15 March 2024

at Milan Exhibition at booth T22 Hall 4 Milan Exhibition, Rho (MI)

MECOLPRESS OPEN HOUSE

Concurrently with the presence at Milan Exhibition, Mecolpress has decided to inaugurate some Open House days and give you the opportunity to see some of our machines directly in our factory.

All our last and innovative mechanical presses (HEAVY\SEO), hydraulic presses (ME) and screw presses (FDS\TDS) will be available to be seen in assembly/testing phase.

Looking forward to meeting you in Mecolpress on the occasion of our Open Days

11-15 March 2024

For further information and to get a free entry ticket to MCE Exhibition, contact us on +39 030 2560110 or write to us at sales@mecolpress.com