THE PRESS AUTOMATICALLY SEPARATES THE FORGED PARTS: GOOD IN ONE BOX, BAD IN ANOTHER!

Differentiated unloading of the forged pieces

The press automatically separates the forged parts and divide them into different boxes. The press has become intelligent!

The differentiated unloading of the forged parts is an interesting function that Mecolpress provides by default on all hydraulic presses, but it can also be added as an option on eccentric mechanical presses.

Hot forging for higher quality of forged parts

The metal hot forging differs from the cold one because it allows you to obtain high quality pieces through an important deformation of the starting material. By working brass, copper, titanium, steel and aluminium by means of hot forging presses, in fact, it is possible to produce particular shapes, even with complex geometries.

The metal hot forging therefore allows to obtain parts that are more resistant than those obtained through other production processes.

In particular, metal hot forging can increase the strength and resistance of the products. For these reasons, the production of hot forged pieces guarantees specific advantages in their mechanical characteristics compared to those produced with other technologies such as casting or mechanical machining with chip removal.

The hot forging, compared to the casting processes, allows to obtain mechanical characteristics and surface appearance of superior quality. We at Mecolpress know it well, so much that we have made “Technology of Shape” our motto.

The piece produced must therefore be perfect, its quality must be certified. For this reason, Mecolpress has designed a system that allows the press automatically separates the perfect forged parts from those to be evaluated as they may not be such.

Why is it so important that the press separates the perfect forged parts from those to be evaluated?

From the automotive sector, the Lean production method teach us:

- Companies can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

- The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

One of the most recurring needs in our customers is to have an ever more intense control of the forging process: the machine must be able to control as many parameters as possible important for the forging process, record them to make statistical predictions on the deviation from the optimal production, carry out checks.

Mecolpress offers a series of forging presses that fully meet the needs described above: the ME hydraulic series.

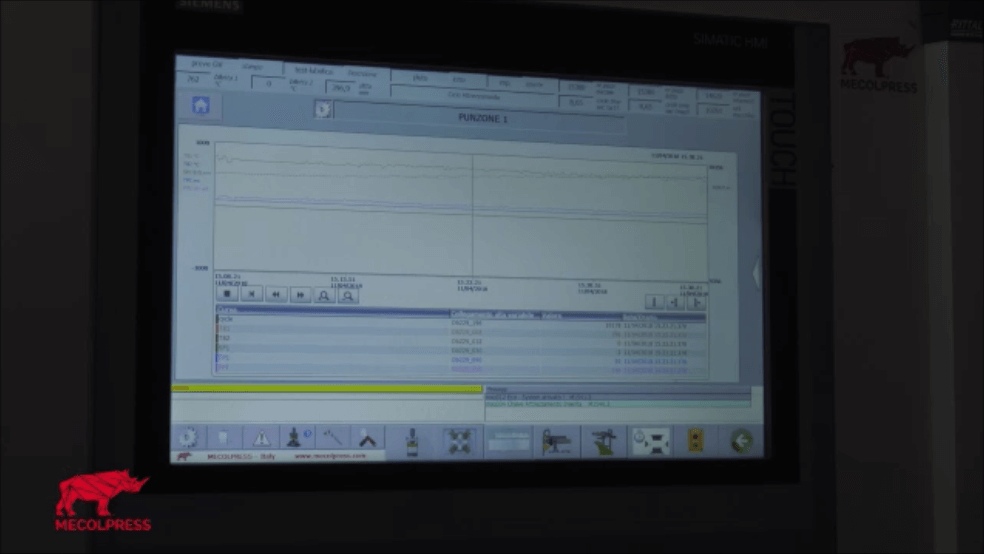

The hydraulic presses can control numerous process parameters and on these manage the logic for rejects or collect the measured values for statistical analysis. For example, they can control:

- the temperature of the billets to be loaded,

- the coring punches penetration time,

- the punches real penetration force,

- the final position reached by each punch.

Here you can learn more about the most important process parameters that hydraulic presses are able to evaluate.

The machines of the ME series have the credentials to be competitive in a modern and controlled forging field; they operate at their best on medium / small batches, thanks to their flexibility.

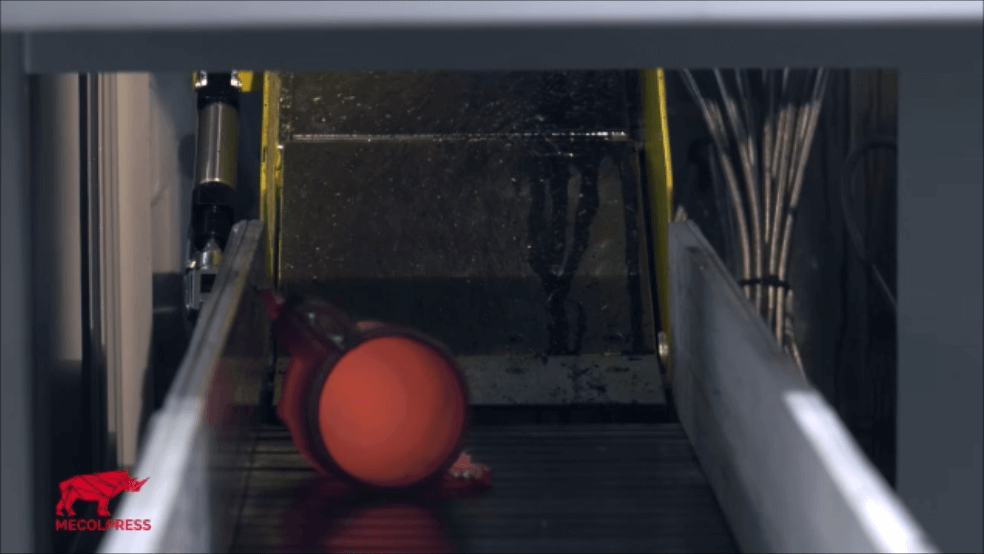

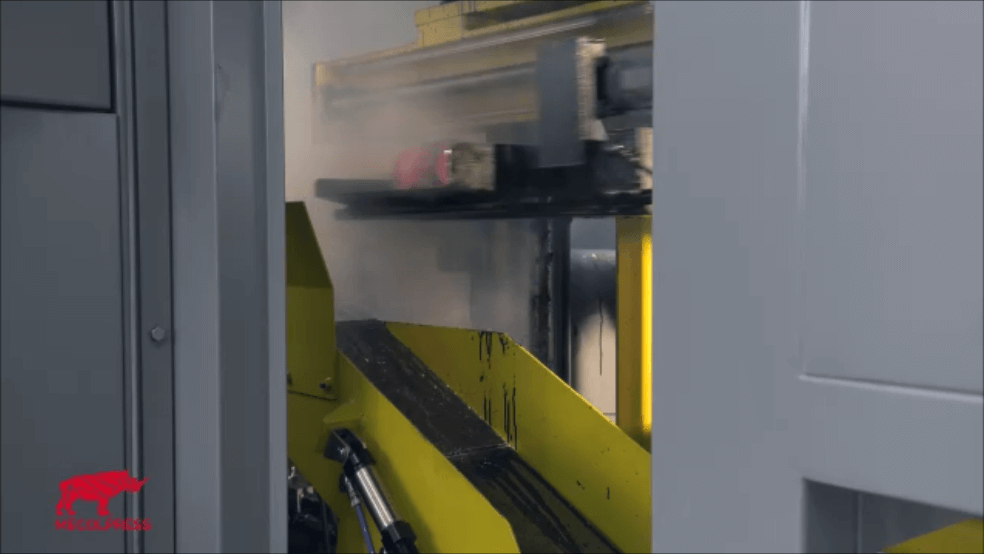

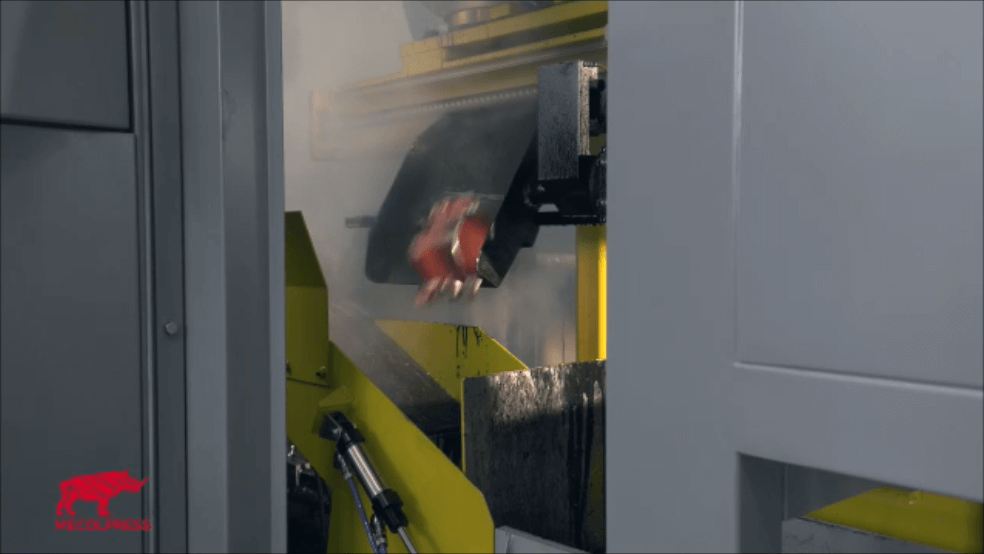

In this video we show how our hydraulic presses perform the differentiated unloading of the forged parts:

The pieces that do not fully comply with the process parameters set by the operator and analysed by our powerful Calipso software to control the forging process, are unloaded in a separate bin.

For the customer this operation translates into an important saving method:

- Less waste of time,

- Less material / pieces to be discarded,

- Be sure that the forged piece complies with the required characteristics,

- Get perfect shapes.

Another company based in Brescia chooses Mecolpress hydraulic presses.

With regularity and continuity, Mecolpress gains new Italian customers, the hydraulic press is confirming to be the winning choice.

Case Study: How we acquired the latest customer from Brescia

We report the case of a new customer based in Brescia that we have just acquired, an interesting case study to understand which are the necessities of the companies working in the hot forging sector and how Mecolpress provides answers.

It is the case of a company established in the international market for the very high quality of its production, consisting mainly of mini valves, valves and fittings for the sanitary and heating sector. This company has its own brass hot forging department, developed to cover the 100% of the forged parts needs; the recourse to very few and highly selected external suppliers happens just in case of particular peak of volumes.

The presses equipment of this company consists of 5 machines, always full of work: 3 more traditional and “dated” (eccentric mechanical presses of the historic producer Rovetta, that now no longer exists) and two more recent little hydraulic presses of a particular type, proposed by an European producer.

Knowing better the company, now customer of us, we could appreciate right from the beginning some undisputed features:

- Advanced transfer machines;

- A working method focused on the precise and deep knowledge of all the productive processes;

- A forward-looking vision on the continuous training of all the personnel that is involved with the management regarding the strategic decisions and that creates a uniform a close-knit group;

- A quality department having knowledge, methodologies and instruments not only for the examination of the parts but also for the evaluation of the method used for their production.

During various meeting both at customer’s and Mecolpress site, we had the opportunity to present them our complete range of presses and in particular the functionalities of our hydraulic presses of ME series.

Mecolpress method

The customer wanted to test us, taking advantage of the Mecolpress strategy of having a selection of presses almost ready for delivery, for carrying out forging simulations with two parts of their production range on the specific press of their interest.

The result was that, thanks to the constructive collaboration of both teams (the customer and the Mecolpress ones), in just 9 weeks from the decision of beginning with the simulations, we could:

- Carry out the forging simulations of the two parts to be tested;

- Manufacture the related forging dies;

- Carry out forging tests with two dies (in manual and in automatic cycle, since Mecolpress has 2 high-performing push-type gas furnaces;

- Dismantle and demolish one of the old presses of the Customer;

- Deliver at customer site in Brescia a new ME150/4G62 hydraulic press, exactly the same one the customer saw and tried.

Why the company under consideration chose Mecolpress?

We thank the customer for the trust and for having tested us, and we are particularly proud that even they, as other customers, after having bought and used the hydraulic presses of our competitors, have chosen to purchase Mecolpress for the future.

The decisive points for this new positive result are in short:

- Mecolpress can offer to the customer not only any kind of new presses, but also exceptional expertise in the maintenance of old presses, of other manufacturers (in this case Rovetta).

- Mecolpress hydraulic presses, both for mechanical and construction project and for extremely developed software, offer to the user an incomparable ease and usage flexibility.

- Choosing Mecolpress, the possibility to conclude an investment in very short time, and to see it becoming rapidly productive; who wants to invest has no time to wait and must be helped to be competitive as soon as possible!

Would you too like to try a forging simulation?

Don’t waste your time,

test us!

Hydraulic Press ME100, the SuperFast!

Forge up to 60 pieces per minute without flash!

Our range of hot forging hydraulic presses ME has been enriched with the latest model ME100. It is a compact machine, dedicated to the forging of low-weight complex pieces, with extremely high productivity.

Mecolpress patented hydraulic presses, suitable for hot forging of standard and special brass or aluminium pieces.

This clamping force is higher than those of traditional mechanical presses. Independent & controlled movements of the ram and punches allow for flash-less hot forging also of complex pieces.

In addition to the ME150, ME250, ME350, we now also offer the ME100:

- 100 Tons of die closing force;

- 30 Tons for each of the punches (there can be up to 5)

- Forge in single or double figure, horizontally or vertically, and it is Super-Fast!

We tested it up to 30 strokes per minute and of course … it was promoted with full score!

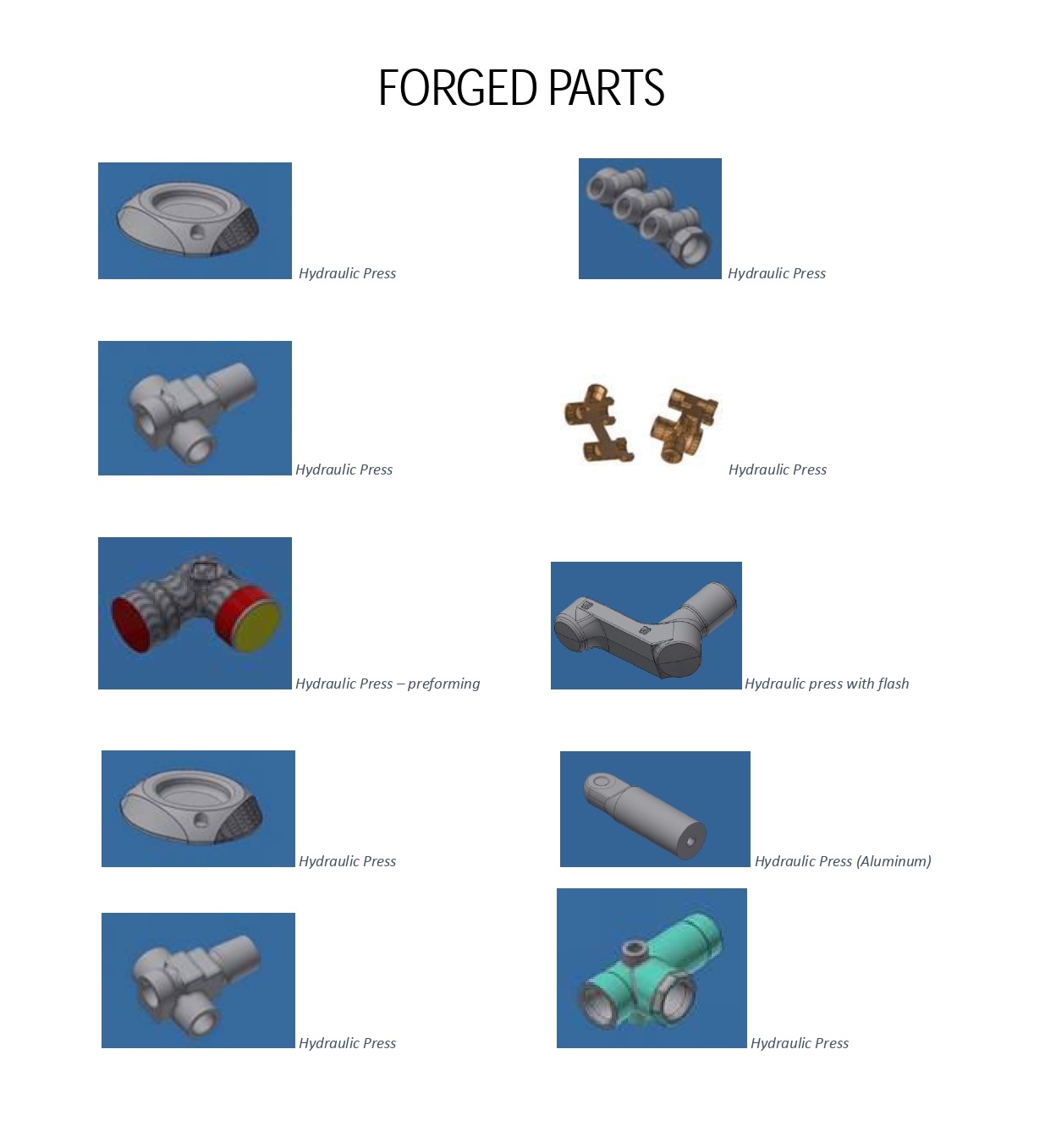

As for all our ME hydraulic presses, the range of pieces that can be forged is very wide.

Here is a photo of typical brass parts that can be forged with this press:

Some info as an example:

– it can print ball valve bodies up to 3/4 inch, without flash (in single figure), or 1/2 inch in double figure.

– Accepts dies size 180x180mm.

– Punches stroke: 75mm.

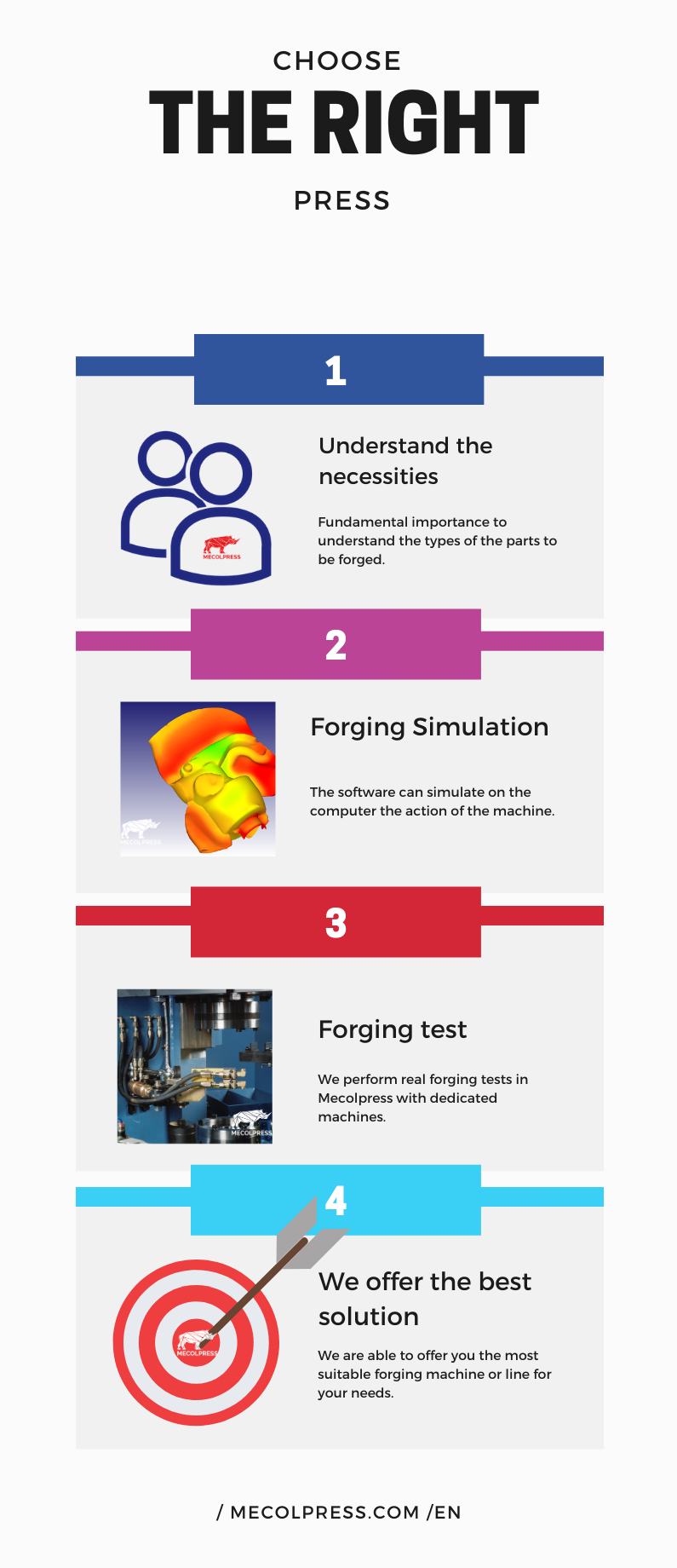

Mecolpress has in fact the skills and the appropriate structure to make you ad hoc consultancy. Through the drawing of the piece you want to forge, we can perform a die simulation through the dedicated software in our internal technical office.

It will also be possible, if necessary, to carry out a real forging test of your piece thanks to the machines that we always have available at our company to carry out forging tests. We are thus able to offer you the machine, or the most suitable forging line for your needs.

And if the right press for you was not the ME100, we are always able to make the specific proposal for the needs of each customer, because Mecolpress has the widest range of hot forging presses of all!

Mecolpress, 50 years in the hot forging sector

This year Mecolpress has reached the goal of its first half century of activity by presenting a new continuous and discontinuous cycle press at EMO exhibition in Hannover, held last September.

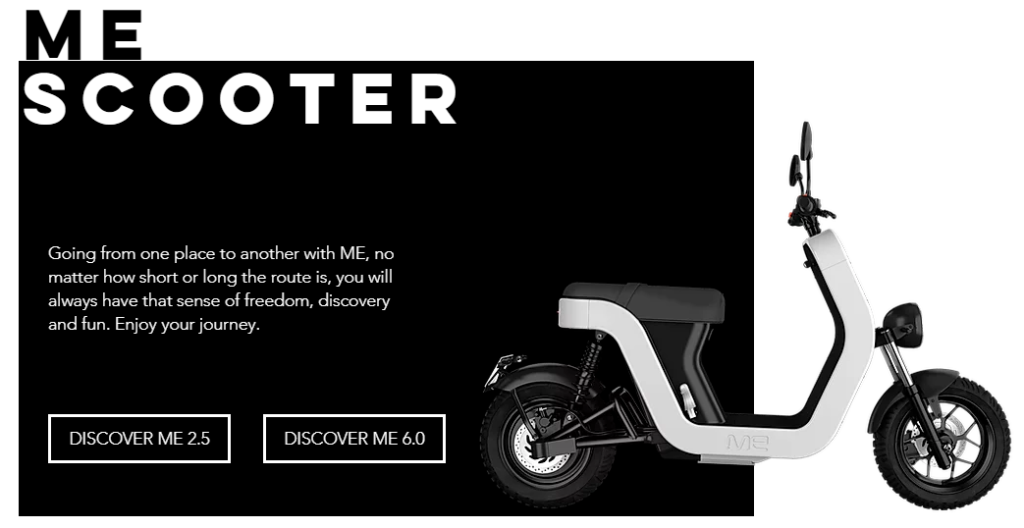

In the present of Mecolpress there is also an investment in the world of electric scooters.

The video story by the management of Mecolpress:

Established in 1969 by Giulio Molinari, Giulio Barbisoni and Pietro Caggioli, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. A few years later, in 1973, the company acquired its current production site in Flero, in via Don Maestrini, initially extended over an area of 2,000 square meters, and then it expanded increasingly reaching 6,000 square meters in 1993. Today Mecolpress has acquired a second industrial area next to the first one where the construction of a warehouse is coming to an end, reaching a total area of 30,000 square meters.

In addition to the industrial area expansion, over the years Mecolpress has aimed higher and higher thanks to the acquisition of two important brands of the screw presses production: the Italian company, Dellavia (1993) and the Swiss company, Osterwalder (1998). The company has always distinguished itself as an avant-garde reality in the forging sector: remarkable are the production of the first continuous cycle mechanical press in 1983, the production of the first continuous cycle electronic press in 1993, the design and construction of the hydraulic press for hot forging of brass components without flash in 2008 and the presentation on the market of the screw press with direct drive motor in 2013.

In September of this year, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

This new machine has an innovative and modern structure, more robust, and designed to simplify the control and maintenance for the operator. The automation and the dies lubrication of the machine was completely renewed, thanks to the addition of a bearing, that allows, among other things, for vibrations reducing and it is provided with a new intelligent software for the production process analysis and for predictive maintenance.

On 31st August, Mecolpress celebrated its first 50 years of activity by opening its doors to the families of the employees who work at the Flero site every day. In this first half century of activity, there have also been moments of sacrifices and difficulties, but the tenacity and determination of its founders allowed Mecolpress to emerge very quickly in a particular market such as the forging one.

The second generation played an important role in the history of the Rhinoceros, as well, in particular, during the economic crisis of 2008, when the company could make courageous decisions, expanding its business, pushing on the accelerator of innovation and research, trying to renew itself and pushing beyond the borders drawn by parents. Now the company has reached the maturity of an important reality that operates all over the world, where the glorious history of its beginnings coexists with the desire to get involved that has especially characterized with research and innovation the last years.

With the background generated by this mix of values, now also the third generation appears in the management panorama.

Watch the video of our Anniversary Party:

Mecolpress, a new adventure

In 2018 Mecolpress acquired the majority of the shares of ME Group, manufacturing company of electric scooters with an unique design, becoming the reference partner alongside the founders. The entry of Mecolpress formally coincided with the passage of ME Group from Innovative Start Up to Innovative SME. This formal transition was in fact also substantial, thanks to the contribution of Mecolpress from a financial point of view and above all from the point of view of know-how and industrial approach to the organisation of the company. ME is the first scooter in the world with a patented frame made of SMC (Sheet Moulding Compound), a compound of thermosetting resins with excellent performances in terms of strength and resistance in relation to its weight. This electric scooter can be recharged like a mobile phone: it can be fully recharged in 3-6 hours (depending on the battery charger used), connecting the scooter directly to a domestic outlet in the garage or office or extracting the battery.

The ME Start Edition version (sold out) was followed by the range available from the 2019 season: 2.5 kW moped model, 45 km/h top speed (limited by law) and 80 km range and 6 kW model with a speed of 80 km/h. Touch display, USB socket and a range of accessories in continuous evolution complete the equipment of ME.

Company numbers:

Mecolpress has grown over the years both in terms of volume of the industrial area and in terms of numbers. Starting from the employment situation: in 1985 Mecolpress had 29 employees, in 2018 it practically doubled its staff to 55 employees. Turnover and production are also growing: in 1985 the company turnover was just over 2.7 million euros. By 1995, turnover rose to 7.5 million euros and then the last available turnover (2018) exceeded 11.3 million euros.

Over the years production has also gone hand in hand with turnover increase. Today Mecolpress has 559 customers in 59 countries worldwide. All over the world there are 1126 Mecolpress machines, including screw presses (101), mechanical presses (806), hydraulic presses (40) and trimming machines (179). Most of them (763) are located in Europe, but the Flero-based company has also exported in Africa (62), Americas (103) and Asia (198).

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..) in the order of more than 1,000 units, bringing the total production of machinery and spare parts to 2183 pieces.

Screw presses

Come to discover the application sectors and the functioning of Mecolpress screw presses. Used for hot forging, these presses can be employed with every type of material and are distinguished by the realization of full parts.

Screw presses functioning

Mecolpress offers a wide range of presses both hydraulic and mechanical. Also screw presses fall into this last category, ideal for hot forging of parts of great dimensions or that require more passages for shaping. These mechanical screw presses can be provided with a disc friction control or a direct control with electric servomotor.

The screw press choice is determined according to the type of part you want to forge. Hallmark of the screw press is its ratio force-machine dimension, that results greater than the specific one of an eccentric mechanical press.

These mechanical presses can be used with every type of material and the frequency of strokes is quite reduced. For this reason, there is a tendency to use this machine for the production of little batches, that is often true for parts of great dimensions.

Mecolpress offers to its customers three lines of screw presses: Dellavia series and Osterwalder series that are friction screw presses, and TDS series with electric motor. All the screw presses models can be integrated with complete and automatic forging lines, that from bar raw material realize finished forged parts.

The tonnage can go from 170 tons up to more than 2.700 tons, to be chosen according to the geometrical shape you want to obtain and of course to the material to be forged.

The applications

The screw presses are used for the realization of parts destined to different application fields including for example, watch cases, parts for sport equipment, for automotive or for biomedical titanium prothesis.

So, it is possible to produce very small parts, such as for example, clothing zipper pullers till to aluminum sport bows of 1 m of length. The parts, produced by this type of machine, are not cored but full.

The screw presses are very used also in the fashion field to realize belt and bag buckles, with brand-specific shape.

In order to understand which model is more suitable to your production needs, all you have to do is to address to Mecolpress sales department. Thanks to the experience gained with years of activity in the hot forging field, we can suggest the most performing machine according to the type of part you want to forge, and it is possible to carry out a test directly at our premises.

Why to choose Mecolpress presses?

Mecolpress makes available to its customers quality presses and all its technologic know how. For those who need high performing machineries for hot forging we are a reliable and with a solid experience partner in this field, gained in many years of activity.

Whether it is an entire forging line or a single machinery, Mecolpress can suggest the most performing solution for production and offer a technical support able to face every need.

A first meeting to understand the necessities

When a new potential customer contacts us expressing its need to buy a press, our sales department organizes immediately a first meeting either at customer’s or at our premises in order to show the different machines and their functioning.

During this phase, to us it is of fundamental importance to understand the types of the parts to be forged and which could be the eventual criticalities connected to the single parts in order to be able to propose the most suitable press. In many cases our offers are based directly on the drawings of the parts to be forged that are analyzed by our technical office in great details.

In order to understand which is the best press, our technical office takes advantage of a software that can simulate on the computer the action of the machine. In this way we provide a valid tool for the identification of the machinery that meets the productive needs.

Some customers in addition to the single press require the entire hot forging line and, in this case as well, we can provide all the necessary machineries, and to optimize the production.

Forging tests at Mecolpress

Once the most fitting press for the customer has been identified, even if this is hydraulic or mechanical, we carry out forging tests at our premises. So, the customer can be sure in advance of the final result before starting the production at his premises.

In order to carry out the test, the dies for the realization of the wished parts are mounted on the machine. In case the customer does not have the die, there is the possibility to commission it directly to Mecolpress. Indeed, our company offers a complete service to support the customer during all the productive steps and can also offer this component.

During the many years of activity we have gained high technical skills and we have confronted with different situations. The gained experience has turned us into a partner that can understand the forgers needs, able to propose mechanical or hydraulic press for a specific production type.

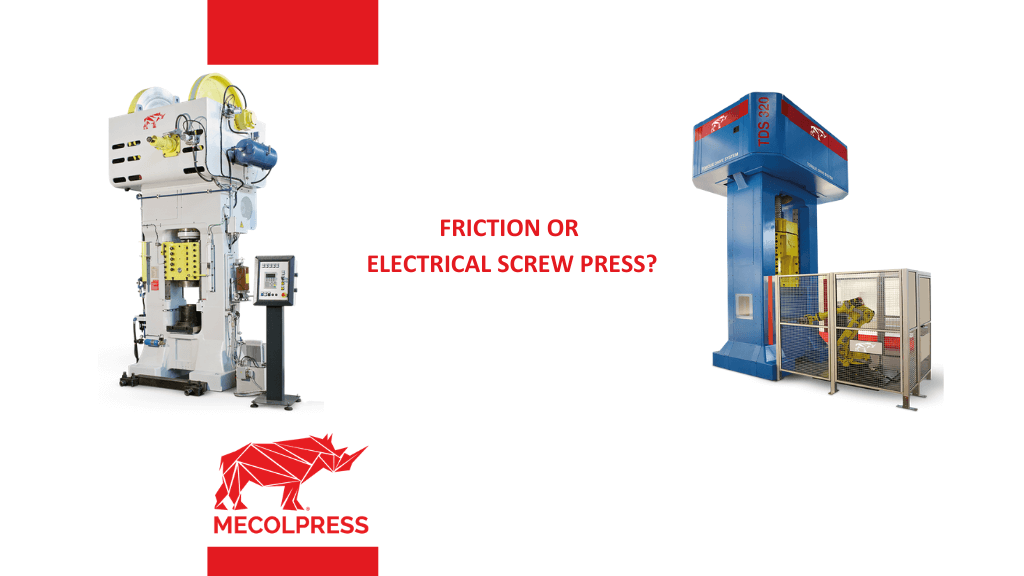

Friction or electrical screw press?

There are electrical or friction screw presses. Which to choose? The choice of the model is linked to the type of parts you want to forge, but also to the press performance. Discover the differences between these types of screw press by reading this article.

The mechanic friction machine is provided with a flywheel that rotates the screws clockwise or counterclockwise so that to let the slide go down or go up. In this case the transmission of the motion from the electric motor to the flywheel happens through the friction created on a leather belt. This model does not permit a direct control of the motor and of the flywheel, even if it presents considerable advantages in terms of energy saving. Indeed, a friction screw press has a medium consumption of about 40 KWh.

These presses require a smaller investment than the one of the screw presses with electrical servomotor, but they need the leather belt replacement, necessary for the slide movement when it wears.

Suitable for the hot forging of every type of material, the friction screw presses are used for the production of full parts.

This press, as opposed to the friction one differs for an electrical motor directly mounted on the flywheel, in the upper side of the machine, that rotates the screw. Thanks to this characteristic, the electrical screw press allows a better control of the productive process. Indeed, it is possible to check the descent and rise speed at any moment, to have direct feedback about the production of the machine and to calculate the necessary tonnage for the hot forging of parts you want to produce.

The electrical screw press requires more electrical energy, but its components wear less, and it is particularly indicated for the production of parts that require more strokes to be completed. In addition, it is possible to obtain much more energy with a reduced stroke, which does not always happen in the case of friction screw press. As a result, this machine has a rate of production slightly higher than a traditional machine.

The mechanical screw presses of Mecolpress TDS series are moreover provided with Calipso software, which is also developed by our company, that allows the data collection and recording in real time. In this way the end-user can do a process evaluation and intervene to optimize it.

Mecolpress proposes to its customers both friction screw presses and direct control with electrical servomotor control screw presses, developed to satisfy the different productive needs and suitable for the forging of full parts destined to sectors such as automotive, medical and sport one.

Training courses for hot forging

Starting from an inner necessity, Mecolpress has extended the training courses specific for hot forging machineries as a high-quality service against payment that can be offered to its customer companies.

Thanks to the course, it is possible to optimize the production and to improve machines maintenance.

The training value according to Mecolpress

Training is very important, especially in an even more complex productive context and in an even more competitive market. That’s why Mecolpress has felt the need to avail itself of the experience of a hot forging specialist to organize an inner training course of high level.

Understanding the world our customers operate in and learning the art of forging in the best way has always been our priority: therefore, we addressed to Riccardo Segreto that in this interview shared with us very useful suggestions and advanced technical information.

Una volta conclusa questa esperienza molto positiva all’interno della nostra azienda abbiamo quindi deciso di offrire questo servizio di alta formazione anche ai nostri clienti.

Advantages of training courses against payment

Training courses represents a very important instrument for the companies that deal with hot forging, because they offer to people who operate with mechanical and hydraulic presses very concrete and deepened indications regarding how to use them in the best way and to optimize the production.

Today it is not easy to find forging specialists that are available to teach trade secrets. Riccardo Segreto is an independent and very skilled figure, available to share with the companies useful suggestions in order not to wear the press or the die and to improve therefore the productive capacity.

Therefore, a highly qualified staff will be able to carry out some maintenance operations in complete autonomy on machineries for hot forging without the need of Mecolpress customer care service against payment. A correct use of the machine brings therefore to lesser damages and a reduction of machine stops that have a big effect on the production and then on the costs to support.

Our training courses against payment are custom-made developed according to customer’s needs and aimed to the types of presses present in the factory of the company that asked for training. Moreover, they provide an in-depth analysis of the parts to be forged and indications on how to forge them in the best way.

Thanks to our specialist, for example, it is possible to learn how to carry out in the best way the die lubrication and therefore how to prevent its wear and how to adjust the machine stroke. Working correctly with the press has as a result a considerable decrease of costs for our customer companies and that’s why we are firmly convinced that our training courses can represent an added value.

According to companies necessities, the courses can be held at our or customer premises and these have a duration of one or two days, according to the specific program.

Should you need further information regarding training courses, you just have to contact our sales department, sending an e-mail to sales@mecolpress.com.

Courses can be requested both by Mecolpress customer and companies dealing with hot forging that have the necessity to examine in depth some themes.

Optimize the production with Mecolpress training courses

Mecolpress makes available to its customers a training service against payment whose aim is to provide useful information to the staff in charge of the presses in order to use the machines in the best performing way and to optimize the production.

Read this article to discover how training could help a customer of ours to reduce of 50% the maintenance interventions.

The problems of customer Alfa

Time ago a customer of ours, that we will name Alfa, contacted us because of his interest in custom-made training courses for forging machines proposed by Mecolpress. The reasons why he decided to activate the course were several.

First of all, the company employees were not adequately trained and could not use the forging machines in the best way. This implicated a frequent request of assistance from Mecolpress by the customer, and even if our intervention was very prompt, the company had to face up to the interruption of the productive process and to the additional costs connected to the customer care service.

In addition, the company hired new young but still not-expert personnel, however definitely open to technologic innovations and able to use the informatic devices of production machineries.

By their side there was also experienced personnel, working in the company for many years, with greater familiarity with forging techniques, but with some difficulties to approach their selves to the new digital techniques. Persuading them to change method was not so easy, because the long experience matured during years with their procedures.

In closing, the Alfa customer has at his disposal a various set of machines including dated presses, trimming presses, mechanical presses and a new hydraulic press, just bought.

For all these reasons, our customer has felt the need to take advantage of a new custom-made training course that can teach to the operators how to use the machines in the most performing way and to obtain the maximum output with minimum effort.

Mecolpress training course

According to the needs expressed by our customers we have planned a custom-made training course that takes account of forging machines in the company and of the type of forged parts.

The course is structured as follows:

- Introduction to hot forging;

- Explanation of drawings and simulation program in support of parts to be forged;

- Parts forging in the factory with an entirely devoted machine;

- Answers to questions of the personnel, detailed studies and explanations on problems regarding the production.

In particular, during the course very relevant matters were debated, such as die and process preliminary analysis, setting of specific parameters, driven setting of the hydraulic presses for parts with flash and without flash and analysis of output with simulations.

Result of the course

Our customer was particularly satisfied with our custom-made training course because of the obtained result.

Indeed, the personnel could acquire an increased competence regarding hot forging, both generally and specific, related to the company production type.

Moreover, the course has contributed to reinforce the team spirit among employees, that is of high importance to create a working environment based on collaboration. Indeed, activities of this kind contribute the personnel to interact more, to better work as a team and also to better face with the daily difficulties.

After our training our customer has decreased drastically the number of service requests against payment. Indeed, the operators in charge of machines can now use better the presses with a lesser wear and they can carry out in autonomy some activities of ordinary maintenance, without the need of Mecolpress technicians.

For further information about Mecolpress training courses, please send an e-mail to: sales@mecolpress.com.

Hot forging of the brass: advantages of this material

The brass and its characteristics

The brass is an alloy composed of lead, copper, zinc and other metals, whose percentage can vary. The main component of this alloy is the copper that has a percentage between 55% and 62%. This high content of copper makes the brass a good electricity conductor and a material of easy mechanical machining because it does not wear out the cutting tools quickly as it instead happens for iron or steel.

Other typical features of the brass are:

- Recycling ease: brass is often remelt and reused to produce new parts.

- Resistance to a wide temperature range: during the hot forging process the brass is able to support, without creating particular critical issues, a moderate temperature range, this simplifies considerably the work, allowing a major tolerance in the usage of machineries.

- Lacking oxidation: During the heating phase inside the die, this metal is not subject to considerable oxidation.

- High corrosion resistance: the brass is a nonferrous alloy and therefore it does not get rusty.

Sectors of brass application

Thanks to its colour similiar to gold, the brass is used also for the realization of ornamental elements, home furnishing pieces such as for example handles and finishing for furniture, elements for clothing, including zippers and belt buckles.

Another sector of particular importance is composed by fluid control. This metal is particularly fitting for the production of valves, junction and fittings; since specific brass alloys with unimportant lead content were realized, the so produced pieces are therefore suitable to the contact with drinkable water. These special alloys are defined as Lead-free

In the end, as already underlined, the brass is a good electrical conductor and this characteristic makes him suitable for the realization of the electrical and electromechanical components, including switch parts, connections and terminals.

The hot forging process of the brass

The brass, that thanks to its particular plasticity permits to produce complicated geometrical shapes with simple processing, is hot forged as follows: when the press closes the dies with a single hit on the billet, it turns it into the part to be realized (in contrast to the steel that needs almost always a sequence of many hits). Inside the two halves of the die, that have the shape of the part to be realized, it is set down an enough quantity of metal in order to perfectly fulfill the entire cavity created by the two dies once they are overlapped and closed.

Presses for brass hot forging

For the hot forging of the brass it is possible to use continuous cycle presses or single cycle presses. The continuous cycle press is provided with a ram that moves continuously without stopping. The billets loading and the forged parts unloading is automatically adjusted by the electronic check. Instead, the single cycle press expects, at the dies reopening after a single hit, that the order for a new descent or closure of the dies must be sent by the user or by the PLC.

Mecolpress presses for the hot forging of the brass

For the hot forging of brass parts, Mecolpress proposes numerous mechanical and hydraulic presses with different characteristics according to the production typology that the customer wishes. Lately we have developed an innovative technology on our hydraulic presses for forging four parts with just a single hit that allows an important saving on the productive costs, come to discover how by reading the article!