The presence of Mecolpress at EMO2017

Mecolpress is constantly participating in EMO at every edition of this event, and this year will bring to the fair its most important innovations that will attract the interest of thousands of visitors.

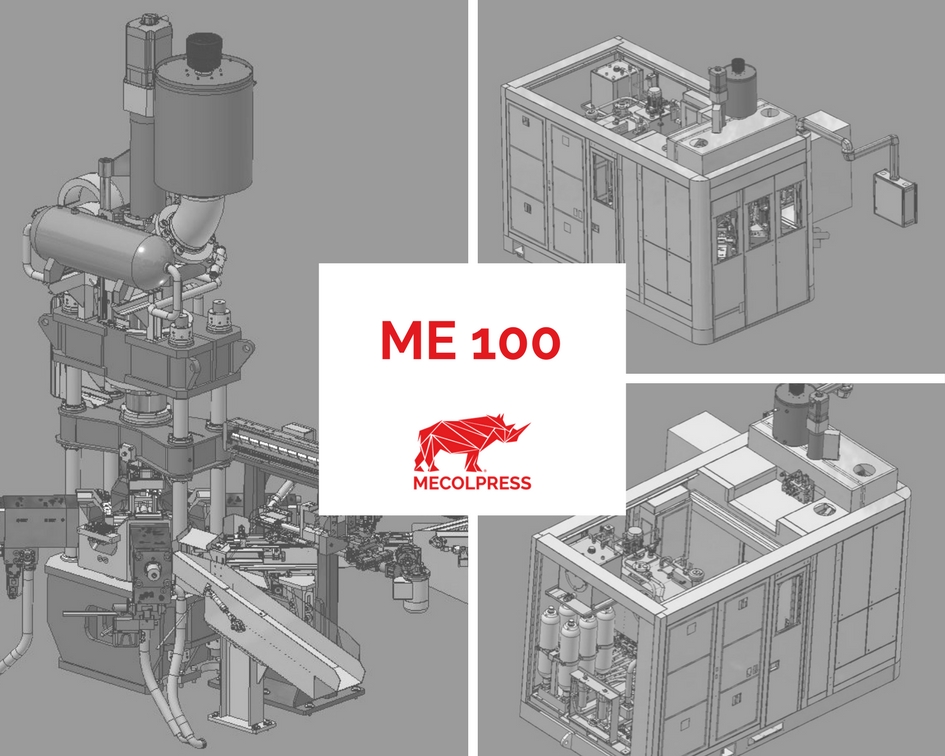

Especially Mecolpress will show EMO2017 for the first time a newly conceived product, a compact hydraulic press for the forging of complex low-weight pieces that ensures a high level of productivity thanks to the different single or double forging solutions that ensures at each corner.

Mecolpress has developed this innovative product that will enrich the lucky series of ME presses ME100-4L-30, based on the many expectations of its customers and the market in general towards a work center that could present high-precision features along with flexibility, ease of configuration and control.

Other innovations that will be presented at EMO2017 are the GBH5000 stand-alone ovens that allow great precision and modularity, effectively connecting to both new and existing presses, hydraulic, mechanical and screw, of Mecolpress or any other manufacturer.

The new hydraulic press with heating-cutting bars online

Presentation of new hydraulic press ME100 / 4L30 with with very high productivity,

Heated+Cutting Bar on-line

The new compact hydraulic press ME100-4L-30 dedicated to the forging of complex shapes with low weight, with extremely high productivity.

The new machine is an evolution of the well-known and appreciated Mecolpress ME hydraulic machines, installed and working all around the world, from Japan, through Korea and China, up to Germany and Italy.

Features:

- Multiples coring possibility, single or double shape forging (parallel or head-to-head), in vertical, horizontal and at any angle.

- Advanced motion solutions to grant highest speed and the most precise control.

- Designed with focus on fast set up and easy access, maintenance and cleaning.

The brass bars heating+shearing furnace GBH5000 is what the market is since long waiting for:

a bar heating furnace, that at the same time can shear into billets, built as a stand-alone unit.

Advantages:

– independent from the press, as furnaces have always been: can be connected to new or existing presses, hydraulic, mechanic or screw presses, and loading automation, of whatever brand;

– allow the user the best flexibility in the production organisation and company development;

– for all lengths of bars up to 5 meters;

– no problems with small diameters;

– no damaging of the brass grain structure because of long-time high-temperature heating.

We will preview the machine at EMO 2017, follow the event.

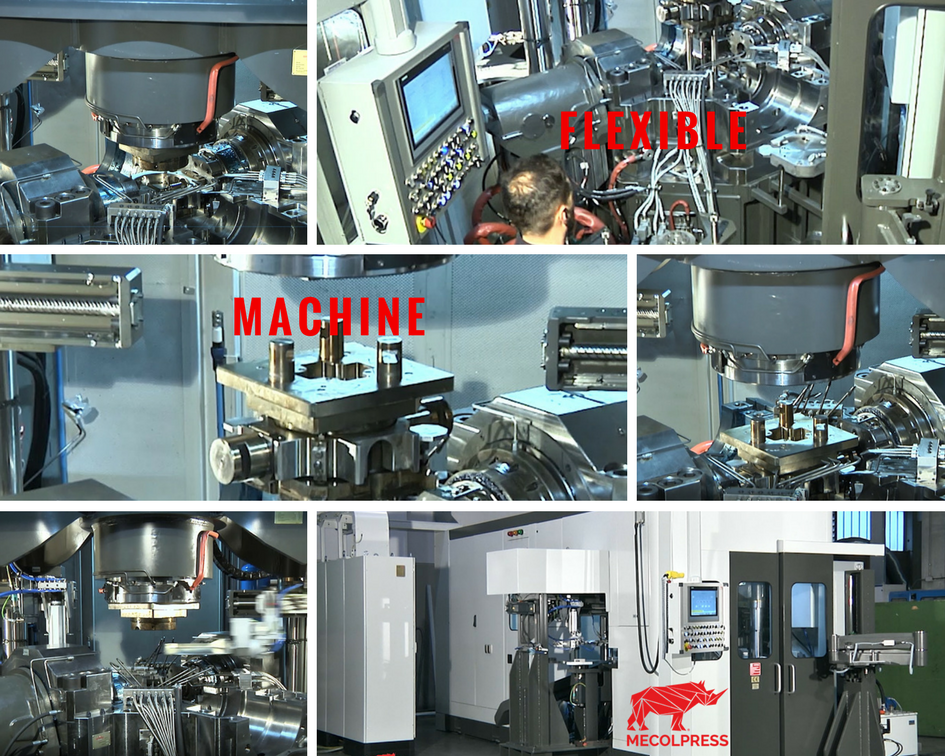

Flexible machine

In the industry, in the last ten years, pushed from the automotive sector, new production methodologies according to the Lean concept are becoming more and more common: in particular, companies that can be competitive on small production batches (producing only what is necessary) instead of manufacturing high quantities at low prices, with the risk of keeping high stock levels, are rewarded with success.

If in the automotive sector this method is since longer time a consolidated strategy, in the HVAC and sanitary industry this tendency has spread out slowly and in a non standardized way, mainly due to the high number of small sub suppliers for hot forged components.

From the bigger players the urgency toward the machine manufacturers is in any case very evident: more than high-productivity equipment, are the machines that can grant very fast set-up and extremely short production change-over time the most requested units.

The second must of the “Lean” work methodology is the zeroing of the waste and dispersions, or in other words, of the useless productions because of defected parts.

To this goal, the most requested ability of the machine is the always deeper control of the forging process: the machine must be able to collect, read and control as many as possible forging parameters, which are crucial for getting a stable-quality output. The machine must as well record these parameters, first to carry out statistical evaluations on the recurrence of deviations from the set standards, and second to allow to conduct analysis (at least at batch level, since the products are not singularly marked and identified) even on later stages, in case of customer complaints.

Mecolpress has in the production program a series of forging presses that are fulfilling in total the above-mentioned requirements:

the ME hydraulic presses range.

The hydraulic presses are designed to reduce the batch change time.

Hydraulic Presses – Parameters

The machine can control several process parameters and through these can manage the logic of defect pieces or generate statistical analysis with the recorder values.

The most important parameters are:

- Temperature of the billets to be loaded: a stable temperature of the billets grant a a constant forging quality and has direct influence on all other forging parameters.

- Coring punches penetration time: it is a good marker of the correct execution of the forging process, being directly connected to the energy required by the piece during the whole penetration stroke.

- Punches real penetration force: gives information similar to the coring punches penetration time, and is influenced by the same parameters.

- Final position reached by each punch: it is the most important parameter to judge if a piece is good or must be scrapped. Excess or lack of material are actually influencing this position, as well as loaded billet with not-correct temperature.

The ME Series machines have all features to be competitive in a controlled, modern forging plant, and perform best on medium and small production batches. These machines can be equipped with gas, or even better with induction furnaces, and with these are suitable to forge diversified materials: brass, aluminium, steel, copper, titanium. As an optional, dies thermoregulation units can be integrated with the machine.

Hydraulic Presses Mecolpress

Hydraulic presses are, by their nature, slightly slower than mechanical units of equal strength but have been designed to reduce batch change time. In particular, the system is equipped with the following features:

- Detection of the piece unloaded by means of piece weighing: a sensitive cell housed on the unloading arm weighs the molded pieces and discriminates if the ejection operation has been successful. The system is simple, robust and allows to set the correct weight value for each piece according to the recipe. No adjustments or cleaning is necessary for photosensitive elements.

- Automatic adjustment of the penetration depth punches also during forging: changing the drilling depth is not a problem, a hydraulic system controlled by an encoder allows the centesimal adjustment of the position of the punches.

- Change dies and punches in a single automatic package: the fixed drilling tool makes it possible to change die and punches in a single operation, the machine automatically cuts the dies and inserts the pins.

- Heating of mdies and external punches in shade with respect to the production: being able to change dies and punches in automatic allows to heat them during the forging operations carried out by means of hydraulic presses, that is in shade with respect to production time. This feature saves more than half an hour for each die change.

- Adjustment of the pressing force of each press and of each individual punch: the press and each individual punch have adjustable forces and speeds within wide margins, this allows to find the correct motion law for each material and for each die.

- Detection of the force exerted by each individual punch for pin damage detection: load cells in the pins provide for the detection of the real force exerted by the punch. This makes it possible to detect piece scraps due, for example, to the punch break, or allows adjustment of the punch energy in order to minimize machine consumption.