EXHIBITIONS 2025: MECOLPRESS AT ISH (GERMANY)

ISH 2025

The world’s leading trade exhibition is the flagship and heart of the healthcare and HVAC industry, as well as a unique driver of innovation. ISH focuses on modern bathroom design, sustainable heating and air conditioning technology and smart home systems. Under the motto “Solutions for a sustainable future”, ISH 2025 will be launched with a new, clear and modern event structure.

It will be held from 13 to 17 March 2025 in Frankfurt at Messe Frankfurt.

We look forward to seeing you at our Booth, Stand Hall 9.1 Stand no. C91

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2024: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2024

Stuttgart Trade Fair Center from 4 to 6 June.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 4 to 6 June 2024 Mecolpress will be in Stuttgart at Castforge Hall 5, Booth 5A37.

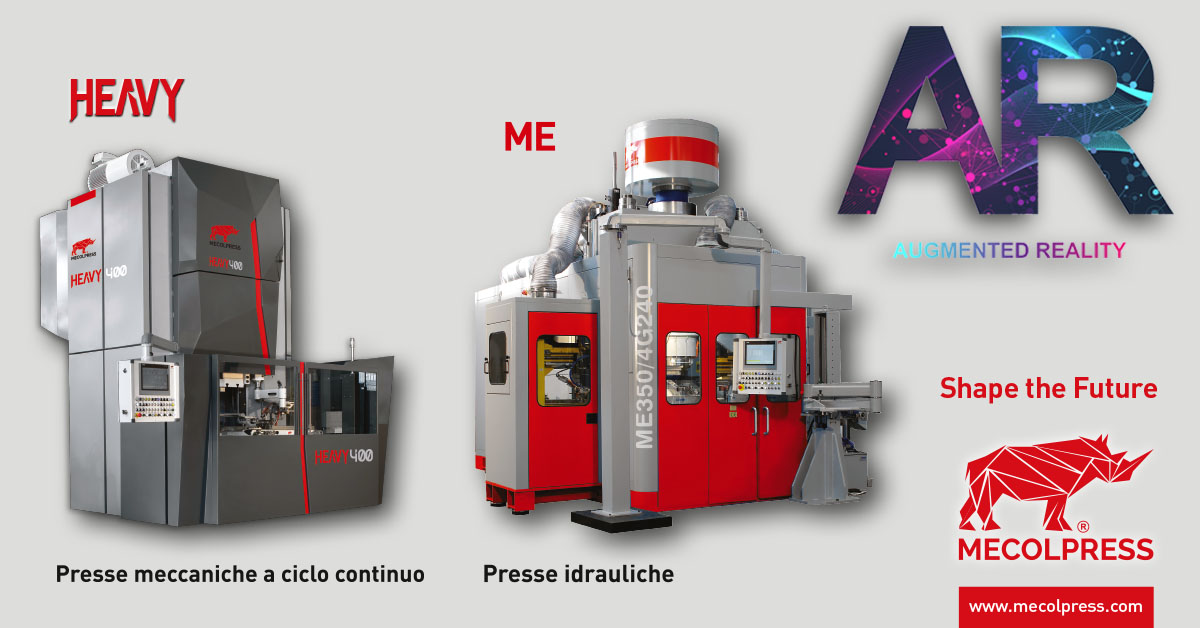

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2024: Mecolpress at AHR (U.S.A.)

AHR 2024

AHR EXPO – CHICAGO

The largest event in the HVACR industry returns to Chicago.

Three days dedicated to the latest energy saving solutions and sustainable technology in the field of heating, ventilation and air conditioning systems.

It will be held from 22 to 24 January 2024, in Chicago at McCormick Place .

We look forward to seeing you at our Booth: South Building – Stand S10262

Mecolpress presents the latest innovations in the field of brass hot forging:

- SEO and Heavy mechanical eccentric presses from 320 to 600 tons, high productivity up to 40 strokes per minute.

- ME series hydraulic presses: flash-free forging with significantly reduced energy consumptions.

- Direct drive screw presses: suitable to produce parts having complex geometry!

Augmented Reality, the press just a click away

On our booth it will be possible to view two presses in Augmented Reality: ME and Heavy series.

This technology allows to overlap multimedia information on the reality framed by the camera of your mobile device, smartphone and/or tablet, enriching the vision of the surrounding space with additional digital contributions.

Get your free admission ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2022: MECOLPRESS AT CASTFORGE (GERMANY)

CastForge 2022

Castforge Exhibition from 21 to 23 June in Stuttgart.

Today costumers of the “Casting and Forging” field are looking for high-quality products ready for installation. As complexity and specific requests are constantly increasing, it is essential to stay on top with the latest news.

This Exhibition represents an important opportunity to meet face to face and discuss these topics in one of the largest markets in Europe.

For this reason, from 21 to 23 June 2022 Mecolpress will be in Stuttgart at Castforge (Stand 5B57).

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

EXHIBITIONS 2022: MECOLPRESS AT BIEMH (Spain)

BIEMH Bilbao 2022

This event will be held at the Bilbao exhibition centre from 13 to 17 June 2022.

Mecolpress will present its latest technological innovations regarding metal forging.

Besides Spanish companies also international ones will be participating in this event, operating in sectors such as: metallurgy, welding, articles and equipment, machine tools, technological solutions, and much more.

You can find us in Pavilion n°5 Stand D34

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free ticket

To facilitate the visit and access in safety, it is appropriate to register to get the free admission ticket.

You can request it by simply filling out this form:

Exhibitions 2022: Mecolpress at GLOBAL INDUSTRIE (France)

Global Industrie Paris 2022

In three editions, Global Industrie has established itself as one of the leading exhibitions in the world dedicated to industry.

Its resolutely modern positioning geared both to the industry of the future and to international business explains the success encountered by its previous editions held in even years in Paris and odd years in Lyon. A geographical diversification which enables it to enhance both its offer and the variety of its visitors.

Global Industrie returns to the capital from the 17th to the 20th of May, at Paris Nord Villepinte.

We are waiting for you Stand 6M91

Augmented Reality, the press just a click away

On our stand it will be possible to view 2 Augmented Reality presses: ME hydraulic press and Heavy Mechanical Forging Presses.

This technology allows to add the multimedia virtual information to the actual view that is captured by the camera of mobile device, smartphone and/or tablet, enriching the surrounding viewing with additional digital contents.

Get your free admission ticket

To facilitate the visit and access safely, it is advisable to register to get the free admission ticket.

You can request it by simply filling out this form:

The dies lubrication determines your forging success!

Knowing to take advantage of the correct dies lubrication is crucial in a hot forging system of brass, steel, aluminum, titanium or copper parts.

We have already highlighted many times in our previous articles how the lubrication can make the difference and solve many of the common problems that the forgers observe during the production of their forged parts. Our research of the perfect lubrication has evolved, becoming more and more precise and customizable, exactly like we are constantly required by the market.

A correct lubrication doesn’t mean that it must be of large quantity, but that it must be correctly dosed and the most appropriate lubricants must be chosen according to the metal types and required part to be forged.

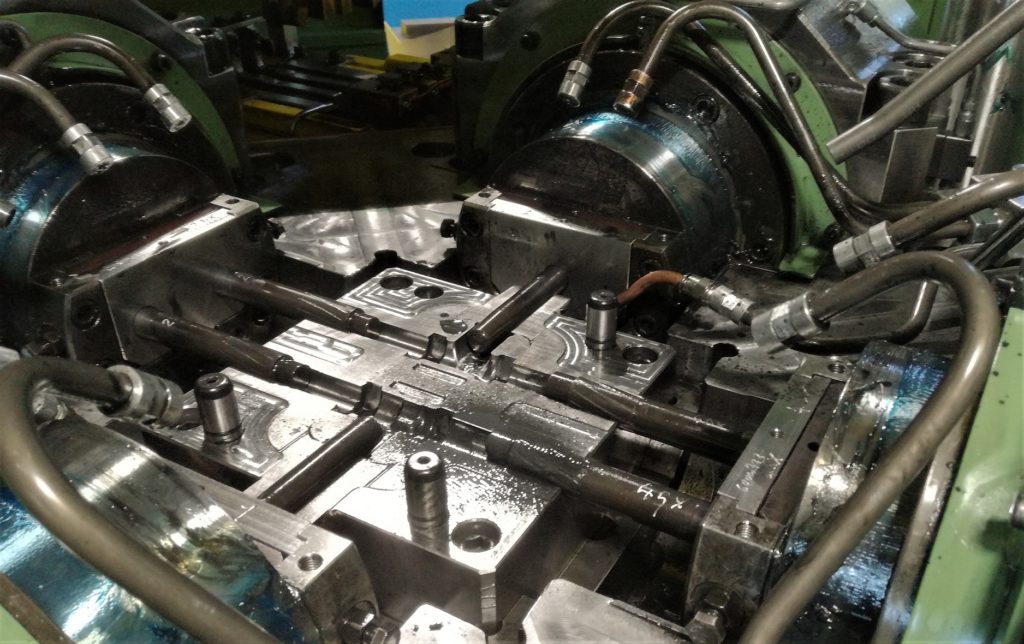

The dies lubrication system of hydraulic presses of ME series and of eccentric press at continuous cycle of HEAVY series

With the hydraulic presses of ME series and the mechanical eccentric at continuous cycle presses of HEAVY series we have revolutionized the dies lubrication system:

- We drag the outgoing oil+graphite mixture on the lubrication point.

- We let the lubrication liquid and the compressed air flow in two concentric tubes of the control valves of the single points up to the usage point.

- For each of the points the pilot is independent and therefore for each of them we give the possibility to the user to choose from the operator panel how, when and how often to intervene.

But we were not satisfied yet!

Which are the requests the forgers most frequently address to us?

We have verified that some of the questions you ask our service department are regarding the lubrication system:

“My die has broken, what can I do to guarantee it a long-lasting life?”

“The dies lubrication system I am using is not satisfying.”

“Is it possible to reduce the waste of lubricants, in view of an even more ecological choice?”

“How can I obtain a successful forging system?”

Our Research and Development team has therefore perfected and developed a new lubrication system.

What’s new in the lubrication system of the HEAVY series

Heavy series is our new proposal of a mechanical eccentric at continuous cycle press. It is a very revolutionary machine, the result of 50 years of experience in the hot forging presses production, and of the continuous search for innovation and technology perfection.

As a result, we have completely reviewed even the automation and the dies lubrication.

First of all, the dies lubrication system allows for each single point the independent and programmable management.

It is possible to start the lubrication cycle in different ways: during the ascent or descent of the ram, during the loading or unloading cycle, with appropriate delay and duration times.

Each point can be used for the nebulization of the lubricant or for the cooling and cleaning of the dies.

The system can be implemented with 2 or more high capacity air blowing points.

It is possible to program the schedules: the pumping circuit, the automatic mixer and the heating resistance placed in the tank allow to prepare the liquid and the entire circuit for the starting time at optimal conditions.

The nebulization of the lubricant, thanks to the particular pipe system, is obtained only in proximity of the usage area: in this way the dosage, repeatability and the sensibility to the dosage variation are guaranteed.

40 lubrication/cooling points are foreseen, of which 16 are placed in the lower dies-holder and 16 in the upper dies-holder. The disposition of the lubrication/cooling points throughout the dies allows to reach efficaciously the critical points to be lubricated/cooled, in addition to drastically reduce the times of production change.

Reactive, smart system for creating your recipes

The responsiveness to the settings variations is immediate, unlike the traditional system that requires several minutes of production before it stabilizes.

In addition to this, we can have a strong blowing without the help of compressors (that are contributing to increase the consumptions and the general maintenances of the plant).

A smart software system helps moreover the operator to adapt automatically the dosage of the lubricant in the startup phase of the production, till to reach the correct forging conditions.

Our system can be adapted even to the use of lubricant/water-base release agent, e.g. used in the aluminum sector, that are different from the classic graphitized oil.

All the parameters, activation of the used points, start modalities, timers and counters, once they have been optimized, are saved in the recipe devoted to the type of the part to be produced, in order that for the following batches of the same article there is a fast production start without useless waste of time.

STEEL HOT FORGING: THE WORD TO OUR EXPERT

We interviewed Luca Di Donato, Mecolpress specialist for steel hot forging.

Steel is a far different material from brass, for this reason Mecolpress has decided to increase its team with a devoted figure, to whom we have addressed some questions.

Let's talk about steel hot forging

What is your role in Mecolpress?

The role I currently play in the company context is project engineer manager specialized in steel hot forging and non-ferrous alloys (except brass).

Specifically, I mainly deal with the identification and definition of the hot plastic deformation process that is technically and economically most suitable for the production of semi-finished steel components but also aluminium and special nickel and Titanium alloys.

What kind of experience do you have in steel hot forging sector?

The gained background in the specific sector derives from many years of work experience acquired in the company field, initially as a designer and then as technical and operational director of companies located in Italy and abroad.

Which application sectors do usually use steel hot forging presses?

Presses for steel hot forging are widely used in many application sectors such as automotive, aeronautics, agriculture, construction, chemical, petrochemical and industrial sector in general.

Which type of machine is most suitable for steel forging? (mechanical presses, hydraulic presses, screw presses?)

From a metallurgical point of view, steel can be forged using every type of press, since the types of steel in general are little affected by the presses deformation speed as some aluminium alloys and the super alloys of Titanium and Nickel are affected.

Therefore, there are other parameters that influence the choice, in fact the geometry, the geometric and dimensional tolerances can certainly guide the choice on a mechanical press rather than on a screw press, but also on a hydraulic press.

Compared to brass, which are the distinctive traits of steel?

From the process point of view and therefore from the point of view of the relative presses, the first aspect that is typical for steel is certainly the forging temperature which is around 1200 ° C.

The other equally important feature is the steel deformability which is far more difficult than the one of the brass. The resistance to hot plastic deformation of steel forces the adoption of simpler geometries, the adoption of presses with increased capacity in terms of forces, moreover, pre-forming processes are often used.

According to your experience, which are the recurring critical issues that you could observe in the forging of this material?

As previously highlighted, steel is forged at high temperature, therefore possible overheating can be created in areas that are particularly subject to deformation, the involved forces are important and as a result the energy and disposition can approach the limit and cause no geometric conformity on the piece.

In the end, steel cannot be easily deformed and therefore it requires a specific study to understand which preforming processes are better to adopt in order to avoid cracks / folds of material.

Always according to your experience, when we want to choose the most suitable machine, what should we absolutely consider?

Obviously the geometry of the forged product to be obtained, together with the imposed geometric and dimensional tolerances, strongly influences the choice of the best process, first of all the type of press but also all the machines necessary to compose the line, from the cutting, heating, and preforming process up to the possible calibration of hot / cold forging.

Mecolpress, through the specific skills acquired in fifty years of working history and thanks to its professionalism, is able to support the customer from the very first stages of defining the most suitable geometry for the choice of the forging up to the realization of the line, also fully automated, turnkey.

What do you think that can really make the difference in a “guessed” press?

The heart of the production line in its entirety is the PRESS which has been designed to respect specific characteristics, as a result “guessing” the type of press is absolutely important, but it is equally essential to consider who designed and built it, in this regard the presses produced by Mecolpress are considered to be among the best on the market, both in terms of technological content and in terms of rigidity and reliability.

If you want further information regarding the topic “Steel hot forging”, we invite you to consult the U.NI.S.A. Italian National Union of Steel Forgers, of which we are aggregate members.

Mecolpress, 50 years in the hot forging sector

This year Mecolpress has reached the goal of its first half century of activity by presenting a new continuous and discontinuous cycle press at EMO exhibition in Hannover, held last September.

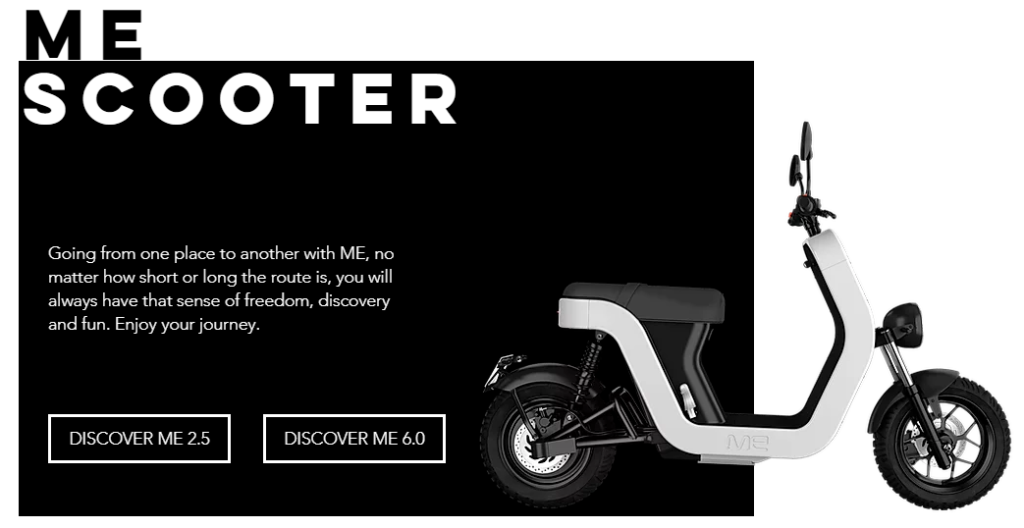

In the present of Mecolpress there is also an investment in the world of electric scooters.

The video story by the management of Mecolpress:

Established in 1969 by Giulio Molinari, Giulio Barbisoni and Pietro Caggioli, MECOLPRESS was founded as a manufacturing company of mechanical presses for brass components hot forging. A few years later, in 1973, the company acquired its current production site in Flero, in via Don Maestrini, initially extended over an area of 2,000 square meters, and then it expanded increasingly reaching 6,000 square meters in 1993. Today Mecolpress has acquired a second industrial area next to the first one where the construction of a warehouse is coming to an end, reaching a total area of 30,000 square meters.

In addition to the industrial area expansion, over the years Mecolpress has aimed higher and higher thanks to the acquisition of two important brands of the screw presses production: the Italian company, Dellavia (1993) and the Swiss company, Osterwalder (1998). The company has always distinguished itself as an avant-garde reality in the forging sector: remarkable are the production of the first continuous cycle mechanical press in 1983, the production of the first continuous cycle electronic press in 1993, the design and construction of the hydraulic press for hot forging of brass components without flash in 2008 and the presentation on the market of the screw press with direct drive motor in 2013.

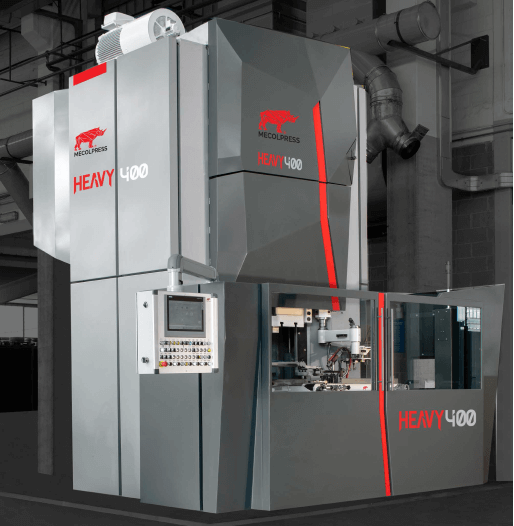

In September of this year, in occasion of EMO exhibition in Hannover, Mecolpress officially presented the new series of continuous and discontinuous cycle eccentric presses, the HEAVY series.

This new machine has an innovative and modern structure, more robust, and designed to simplify the control and maintenance for the operator. The automation and the dies lubrication of the machine was completely renewed, thanks to the addition of a bearing, that allows, among other things, for vibrations reducing and it is provided with a new intelligent software for the production process analysis and for predictive maintenance.

On 31st August, Mecolpress celebrated its first 50 years of activity by opening its doors to the families of the employees who work at the Flero site every day. In this first half century of activity, there have also been moments of sacrifices and difficulties, but the tenacity and determination of its founders allowed Mecolpress to emerge very quickly in a particular market such as the forging one.

The second generation played an important role in the history of the Rhinoceros, as well, in particular, during the economic crisis of 2008, when the company could make courageous decisions, expanding its business, pushing on the accelerator of innovation and research, trying to renew itself and pushing beyond the borders drawn by parents. Now the company has reached the maturity of an important reality that operates all over the world, where the glorious history of its beginnings coexists with the desire to get involved that has especially characterized with research and innovation the last years.

With the background generated by this mix of values, now also the third generation appears in the management panorama.

Watch the video of our Anniversary Party:

Mecolpress, a new adventure

In 2018 Mecolpress acquired the majority of the shares of ME Group, manufacturing company of electric scooters with an unique design, becoming the reference partner alongside the founders. The entry of Mecolpress formally coincided with the passage of ME Group from Innovative Start Up to Innovative SME. This formal transition was in fact also substantial, thanks to the contribution of Mecolpress from a financial point of view and above all from the point of view of know-how and industrial approach to the organisation of the company. ME is the first scooter in the world with a patented frame made of SMC (Sheet Moulding Compound), a compound of thermosetting resins with excellent performances in terms of strength and resistance in relation to its weight. This electric scooter can be recharged like a mobile phone: it can be fully recharged in 3-6 hours (depending on the battery charger used), connecting the scooter directly to a domestic outlet in the garage or office or extracting the battery.

The ME Start Edition version (sold out) was followed by the range available from the 2019 season: 2.5 kW moped model, 45 km/h top speed (limited by law) and 80 km range and 6 kW model with a speed of 80 km/h. Touch display, USB socket and a range of accessories in continuous evolution complete the equipment of ME.

Company numbers:

Mecolpress has grown over the years both in terms of volume of the industrial area and in terms of numbers. Starting from the employment situation: in 1985 Mecolpress had 29 employees, in 2018 it practically doubled its staff to 55 employees. Turnover and production are also growing: in 1985 the company turnover was just over 2.7 million euros. By 1995, turnover rose to 7.5 million euros and then the last available turnover (2018) exceeded 11.3 million euros.

Over the years production has also gone hand in hand with turnover increase. Today Mecolpress has 559 customers in 59 countries worldwide. All over the world there are 1126 Mecolpress machines, including screw presses (101), mechanical presses (806), hydraulic presses (40) and trimming machines (179). Most of them (763) are located in Europe, but the Flero-based company has also exported in Africa (62), Americas (103) and Asia (198).

In addition, Mecolpress is particularly active in after-sales service. The heart and pride of Mecolpress is its large spare parts warehouse, which is able to supply accessories or spare parts for machines produced fifty years ago. For this reason, in addition to the sale of machinery, there is a wide activity related to the service and supply of accessories (such as tools, arms, spare parts, etc..) in the order of more than 1,000 units, bringing the total production of machinery and spare parts to 2183 pieces.

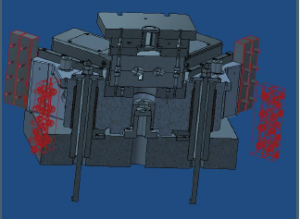

HEAVY SERIES MECHANICAL PRESSES

Mecolpress, at the EMO exhibition in Hannover which took place last September, officially presented the new series of eccentric continuous cycle mechanical presses, the HEAVY series.

Based on the experience accumulated over 50 years of designing and manufacturing presses for hot forging metal, we have succeeded in creating a totally renewed mechanical press.

We are sure that our new project will mark the beginning of a new era for hot forging!

What are the main strengths of the new HEAVY mechanical presses?

-

- A structure that is certainly innovative and modern, more robust and designed to simplify control and maintenance;

- Fully revised die automation and lubrication;

- Our innovative hydraulic cushion, the Soft-Impact, which allows to achieve important results including for example the possibility of vibrations reducing;

- The updated version of our intelligent Calipso software, for the analysis of the production process and for predictive maintenance.

Let's analyse the features in detail:

STRUCTURE

The structure of the machine is made in such a way as to separate the dangerous area (moving parts and die area) from the areas accessible to the operator for adjustments and ordinary maintenance, through front protections and soundproofing material casings, as required by CE standards.

Directly on the vertical part of the forging area, the fume extraction is obtained through metal ducts with connection to the customer’s centralized system.

The control unit for centralized lubrication of the press, the regulators of the pneumatic system and of the die lubrication system and the electrical equipment are inserted in large protected cabinets and easily accessible to the operator, not reached by the fumes and the oil of die lubrication .

The assembly of the main parts to the machine is designed to simplify inspection and maintenance.

COMMAND GROUP

It includes a compact transmission coaxial to the eccentric shaft including:

– Combined flywheel and reduction unit;

– Combined Hydraulic Brake-Clutch Group, equipped with progressive piston to mitigate shocks and transmission vibrations due to engagement and braking;

– Control valve of the Brake-Clutch group with progressive engagement and braking control;

– Double gear coupling between eccentric shaft and transmission to avoid the transmission of shocks from the crank mechanism to the control unit;

– Main motor with encoder and closed loop control, allows the slow movement of the press for tooling, “Inching mode”.

The flywheel motor system has been completely revised to obtain better resolution and precision in speed control, greater reactivity in the recovery of energy after forging.

A safe speed limit control is foreseen with open front protection, during the set-up phases and a check of a possible excessive slowing down of the machine (for example due to a too large billet).

The motor cooling is constantly ensured regardless of the motor speed, this allows to always guarantee maximum performance.

We have provided an interesting option: the energy that the motor returns to the inverter during the slowdown phases, is put back into the network and not dissipated in heat; in practice it translates into a lower consumption of electricity!

SLIDE

Also the slide has been revised, we have foreseen a motorized adjustment of the vertical light and an extraction bar with hydraulic control.

The sliding skids are oriented radially to the machine axis to reduce the variation of the tolerances with changing temperatures.

The hydraulic system for protection against overload is also inserted in the slide, which is essential for forging on the bottom.

GE EQUIPMENT

– Possibility of mounting the lower punch also with “SOFT IMPACT” cushion,

– Water cooled upper die holder,

– Up to 8 points of lubrication from the lower die holder,

– Up to 4 points of lubrication from the upper die holder,

– Easy equipment change. It is extracted by unlocking the top with pistons that allow extraction on a ball guide.

– Possibility of mounting the motorized adjustment of the punch stroke.

For the HEAVY400 the GE26 is foreseen, which has the following specific features:

– Dies 290 x 290 mm

– 110 mm punch stroke

Thanks to our Extruder Group you can save up to 40% of the material compared to the full forging modes! Check out the details here

“SOFT IMPACT” CUSHION

1000 kN hydraulic cushion with complete electronic management, it allows to check the punch height, in addition to limiting the mechanical shock due to the impact between the dies.

The Soft Impact cushion is an important innovation that we have been making for a couple of years, and that is proving to be truly appreciated. Read here to learn more about how it works.

BRCE LOADING DEVICE

The 2-axis rotary loading arm driven by brushless motors has the load angle of the clamp at 45 °, aligned with the dies centre;

The 400 mm vertical stroke allows you to manage any type of equipment without manually changing the position of the arm.

PBSE DISCHARGE DEVICE

The discharge chute has been designed to avoid dents to the forged part; driven by a motor brushless, the unloading arm allows automatic adjustment of the position.

DIE LUBRICATION

We have provided up to 20 lubrication points and 2 dies blowing points, an open and flexible configuration for each type of die and tool.

Also interesting is the possibility of adjusting the amount of oil from the panel, without need of manual adjustments on the machine and on the control unit.

From every point it is possible to blow air to clean / cool the die before every lubrication.

The press is able to warn in advance when it is necessary to fill the hydraulic unit, in order to avoid a machine stop due to lack of fluid.

A digital sensor allows the control of the fluid temperature, the operator can start the production only when the oil is at the correct temperature, an essential requirement for a correct and constant lubrication.

An inverter for pump speed adjustment prevents overpressure peaks and oil dripping when the pump starts with oil still cold; automatically adjusts the oil flow rate according to the quantity needed for use; prevents overheating of the oil in the control unit.

Our lubrication system, unlike the systems marketed up to now, eliminates the problem of the quantity of oil usable for each individual nozzle.

Competitive lubrication systems load a limited amount of oil into a tube and then blow it off with compressed air.

This ensures that 70% of the sprayed lubricant is used only in the first moment of lubrication, while in the remaining cycle the quantity of lubricant decreases until it is completely zeroed.

On the other hand, our lubrication system allows continuous and constant mixing directly at the exit point of the pipe, through our system we can cool and lubricate the dies from the same pipe without affecting the programmed oil quantity.

ELECTRICAL CONFIGURATION

The 24vcc circuits are protected by auxiliary electronic devices, able to provide a quick diagnosis of any short circuits or overloads (also through Teleservice).

This is a very interesting aspect because it allows a greater reliability of the system and a service life up to 10 times greater than normal technology!

The cables are in PUR, protected by steel sheaths and silicone protections against flames, specific for use even in environments deemed aggressive.

OPERATOR INTERFACE

The Operator Panel is a 15 ″ Siemens Touch Panel to better manage machine data, you can save up to 1000 recipes! And have an alarm history with up to 10,000 events.

Obviously, through the proper configuration of our software, you can receive valuable reports to carry out preventive maintenance.

Another practical example is the notepad function, thanks to which the operator can then write important information and his personal notes, added to each production recipe.

It is possible to obtain a production report, a secure management by 4-level password with autologon function, and much more.

Finally, the movable panel allows close controls on the machine, possibility of movement and programming with front or rear open protection, close to the die (eg die lubrication).