CO-ENGINEERING TO DEVELOP MECHANICAL PRESSES

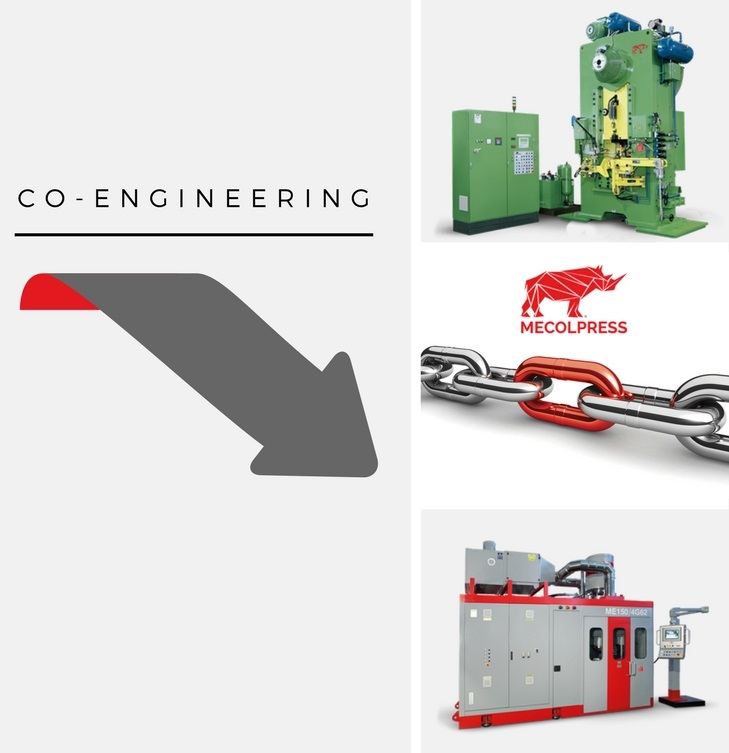

Co-Engineering makes it possible to create customized Mechanical Forging Presses and Hydraulic Presses

Mecolpress manufactures mechanical presses, hydraulic presses, used mechanical presses and used hydraulic presses, carefully revised, developing projects and new ideas from a close and constant collaboration with their customers and carefully selected partners.

This allows you to make great initiatives based on the professionalism, seriousness and trust of those who collaborate, sharing the best of the technological skills and design capabilities of everyone.

Mecolpress designs and constructs totally a complete range of hot forging machines such as: mechanical presses, hydraulic presses, friction and electric screw presses, trimming presses and knuckle joint press.

Through a co-engineering activity he also succeeded in offering complete forging systems that could include:

- Anthropomorphic robots

- Design of pneumatic and electronic arms based on customer requirements

- Transfer systems for forging

- Integrated or press-independent dies lubrication and cooling systems

- Forged pieces cooling systems

Mecolpress is responsible for the direction and coordination of the works.

As CEO, we are able to ensure continuity, support, and timely advice.

What enables Mecolpress to be at the forefront of Co-engineering activities designed to produce hot forging machines?

- the high number of projects completed,

- our experience in hot forging started in 1969,

- our constant presence on international markets.

All this has allowed us to gain considerable experience in the industry and to offer reliable service.

Getting a perfect forging solution becomes possible with Mecolpress:

- We reach an objectives set with the customer,

- We continually seek innovative solutions to achieve the perfect shape forming technology,

- Our R & D team is constantly committed to meeting the different needs of the customer.

These have always been the cornerstones of our mission.